Radiating fan controlled by moment of force and used for servo motor

A servo motor and cooling fan technology, which is applied to the components, electromechanical devices, electrical components, etc. of the pumping device for elastic fluid, can solve the problems of complicated wiring, decreased ventilation, and decreased heat dissipation capacity of the motor, so as to reduce the extra cost. Wiring, reduce fan noise, prevent the effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

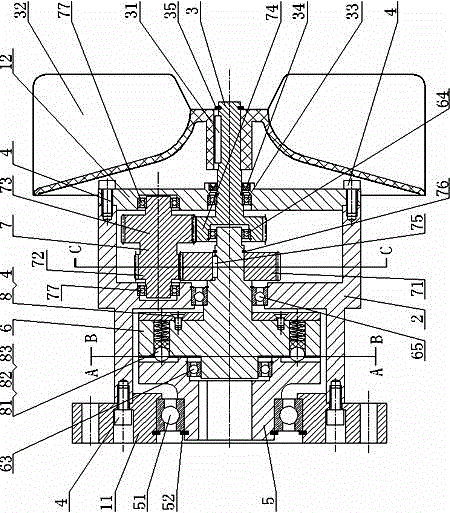

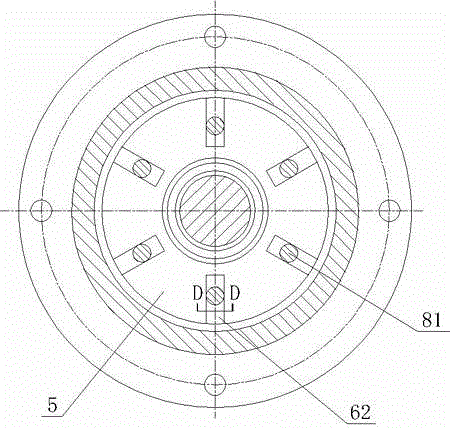

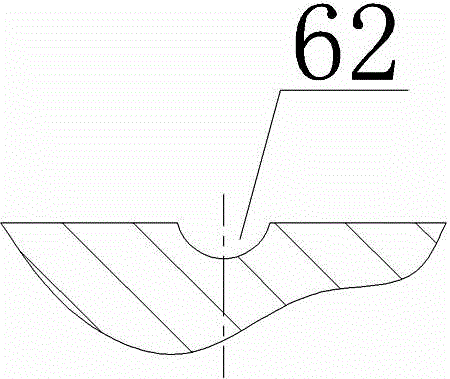

[0033] A torque-controlled cooling fan for a servo motor, comprising a front end cover 11, a rear end cover 12, a housing 2, a fan shaft 3, a fan key 31, a fan blade 32, a fan shaft bearing 33, and an oil seal 34 , Fan blade retaining ring 35, screw 4, disc shaft 5, disc shaft bearing 51, disc shaft retaining ring 52, intermediate disc shaft 6, front intermediate disc shaft bearing 63, rear intermediate disc shaft bearing 64, intermediate disc shaft bearing 65, Gear shaft 7, first-level gear 71, second-level gear 72, third-level gear 73, fourth-level gear 74, gear key 75, gear retaining ring 76, gear bearing 77, pressing plate 8, steel ball 81, steel ball sliding shoe 82 and spring 83, such as Figure 1 to Figure 5 As shown, the specific structure is:

[0034] The two ends of the housing 2 are respectively fixed with the front end cover 11 and the rear end cover 12 by screws 4, and the middle part of the inner cavity of the housing 2 is provided with a ring-shaped partition 2...

Embodiment 2

[0045] A torque-controlled cooling fan for a servo motor, comprising a front end cover 11, a rear end cover 12, a housing 2, a fan shaft 3, a fan key 31, a fan blade 32, a fan shaft bearing 33, and an oil seal 34 , Fan blade retaining ring 35, screw 4, disc shaft 5, disc shaft bearing 51, disc shaft retaining ring 52, intermediate disc shaft 6, front intermediate disc shaft bearing 63, rear intermediate disc shaft bearing 64, intermediate disc shaft bearing 65, Gear shaft 7, first-level gear 71, second-level gear 72, third-level gear 73, fourth-level gear 74, gear key 75, gear retaining ring 76, gear bearing 77, pressing plate 8, steel ball 81, steel ball sliding shoe 82 and The spring 83, the intermediate disc shaft 6 and the intermediate disc 61 are provided with 4 through holes parallel to the central axis. The central angle of the arc is 120°. Other structures and usage methods are all the same as in Embodiment 1.

Embodiment 3

[0047] A torque-controlled heat dissipation fan for a servo motor, comprising a front end cover 11, a rear end cover 12, a housing 2, a blade shaft 3, a blade key 31, a blade 32, a blade shaft bearing 33, and an oil seal 34 , Fan blade retaining ring 35, screw 4, disc shaft 5, disc shaft bearing 51, disc shaft retaining ring 52, intermediate disc shaft 6, front intermediate disc shaft bearing 63, rear intermediate disc shaft bearing 64, intermediate disc shaft bearing 65, Gear shaft 7, first-level gear 71, second-level gear 72, third-level gear 73, fourth-level gear 74, gear key 75, gear retaining ring 76, gear bearing 77, pressing plate 8, steel ball 81, steel ball sliding shoe 82 and The spring 83, the intermediate disk shaft 6, and the intermediate disk 61 are provided with 8 through holes parallel to the central axis. The central angle of the arc is 150°. Other structures and usage methods are all the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com