Cast-in-place concrete major-diameter pipe pile body strain monitoring method based on BOTDA

A large-diameter pipe and strain monitoring technology, used in measuring devices, instruments, material analysis by optical means, etc., can solve the problems affecting the integrity and strength of cast-in-place concrete large-diameter pipe piles, the complex operation of strain gauges, and the connection of strain gauges. There are many problems such as many lines, so as to achieve the effect of anti-high voltage and anti-interference ability, simple construction and wiring, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

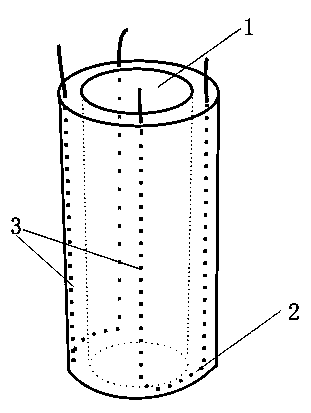

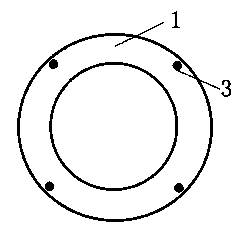

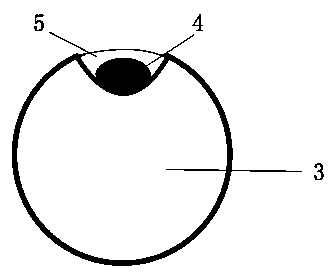

[0021] Embodiment: the cast-in-place concrete large-diameter pipe pile monitored in this embodiment is such as figure 1 As shown, the pile body 1 is included, and a pair of carrier reinforcement bars are embedded in the cast-in-place concrete of the pile body 1, and the carrier reinforcement bars include arc-shaped reinforcement bars 2 and a pair of vertical reinforcement bars 3 connected to each other. Such as figure 2 As shown, a pair of carrier steel bars are symmetrically arranged in the pile body 1 , and the tops of the vertical steel bars 3 are located at the top of the pile body 1 . Such as image 3 As shown, the sensing optical fiber 4 is fixed in the groove provided on the curved steel bar 2, and the groove is also filled with epoxy resin 5. Such as Figure 4 As shown, the end of the sensing fiber 4 is covered with a protective sleeve 6 .

[0022] When in use, the BOTDA-based method for monitoring the strain of the cast-in-place concrete large-diameter pipe pile ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com