Once molding construction method of beam-type conversion layer of high-rise building by steel pipe supporting and laminated pouring

A beam-type conversion, high-rise building technology, applied in the direction of construction, building structure, building materials, etc., can solve the problems of long construction period, beam and slab engineering quality impact, etc., to facilitate construction operations, avoid adverse effects, easy quality The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

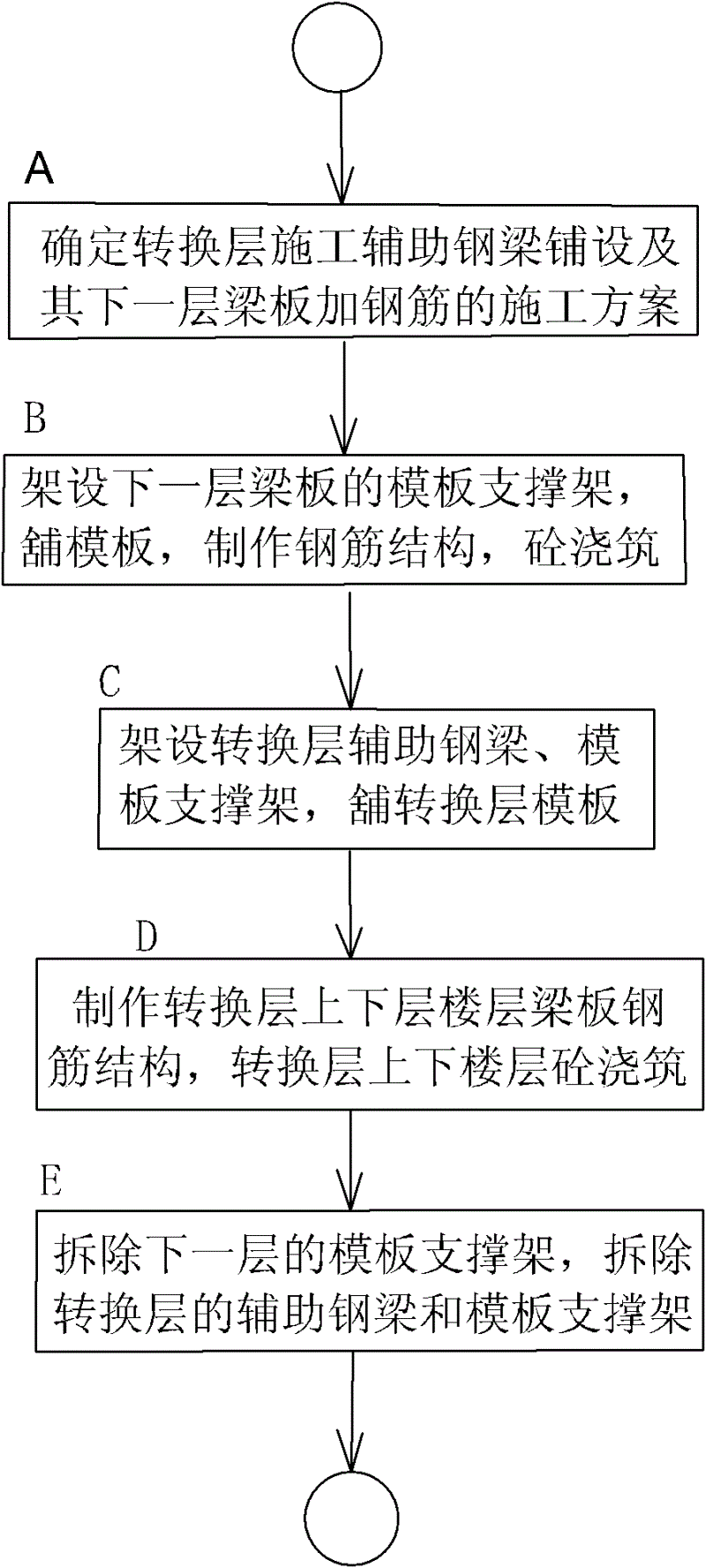

[0020] The main construction process of the high-rise building beam-type transfer layer steel pipe support superimposed pouring one-time forming construction method of the present invention is as follows figure 1 Shown:

[0021] Step A, determine the scheme of adding reinforcement to the auxiliary steel beams of the transfer floor and the beams and slabs of the first and second floors of the transfer floor. In the structural design stage of high-rise buildings, due to consideration of wind loads and earthquake loads, the load effect is reflected in the lower beams and columns with larger cross-sectional dimensions, more reinforcement, and higher bearing capacity. During the construction of the lower part, since the upper load, construction vibration load and most of the wind load have not been applied to the structure, the beams and columns of the lower part of the structure have a large bearing capacity reserve. During the construction of the transfer floor, the bearing capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com