Surface treatment process method before wiredrawing of welding wire

A technology of surface treatment and process method, which is applied in the field of continuous surface treatment, can solve problems such as low production efficiency, environmental pollution, and long pickling time, and achieve the effects of preventing over-corrosion, eliminating pollution, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

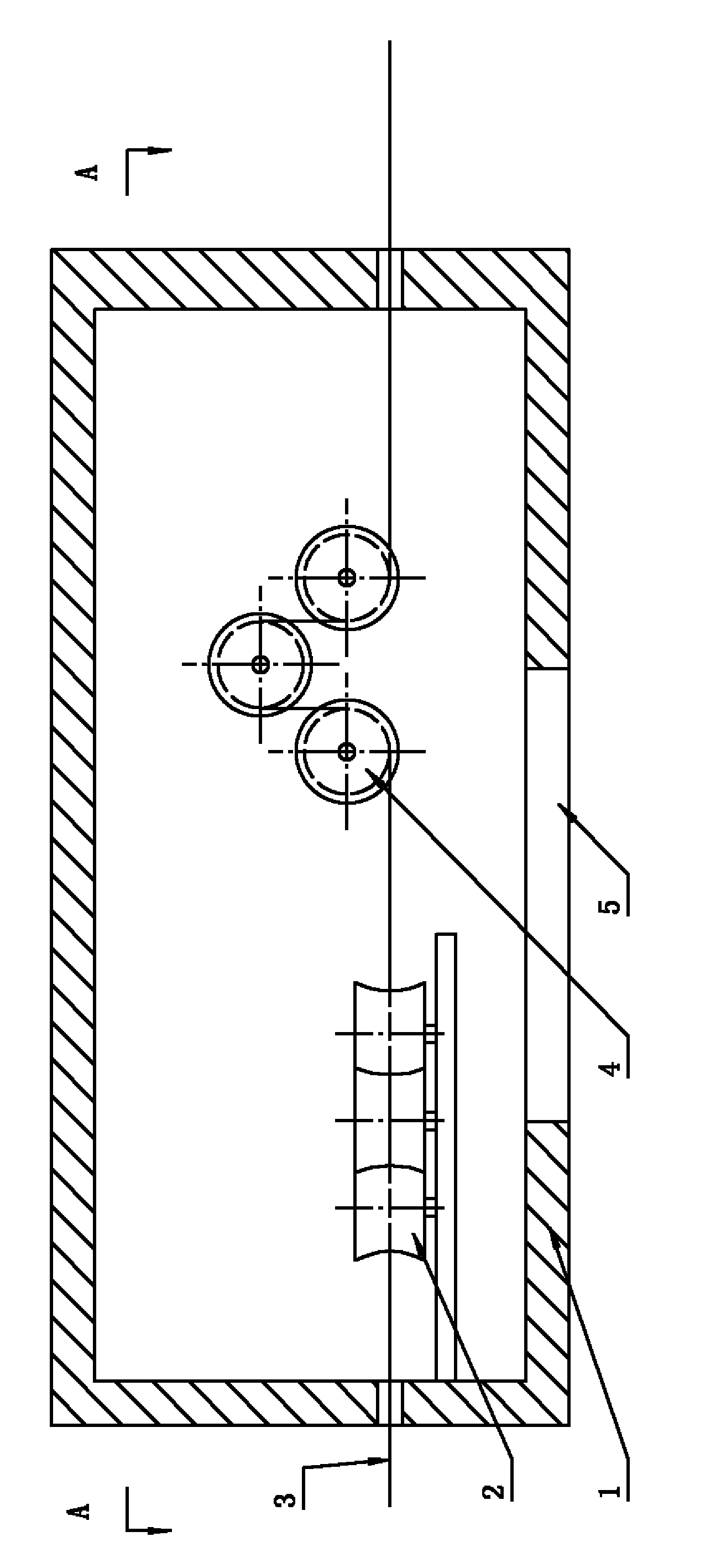

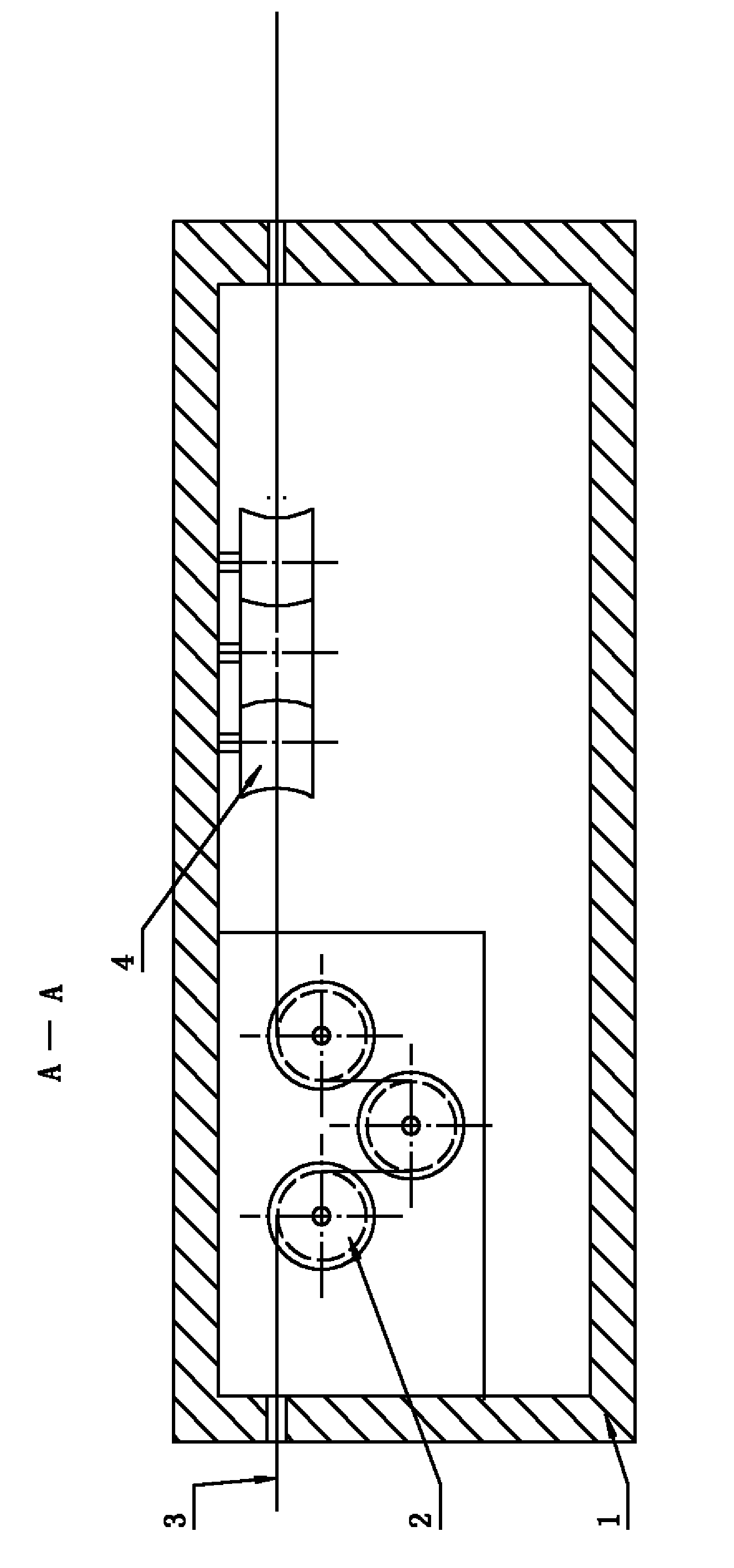

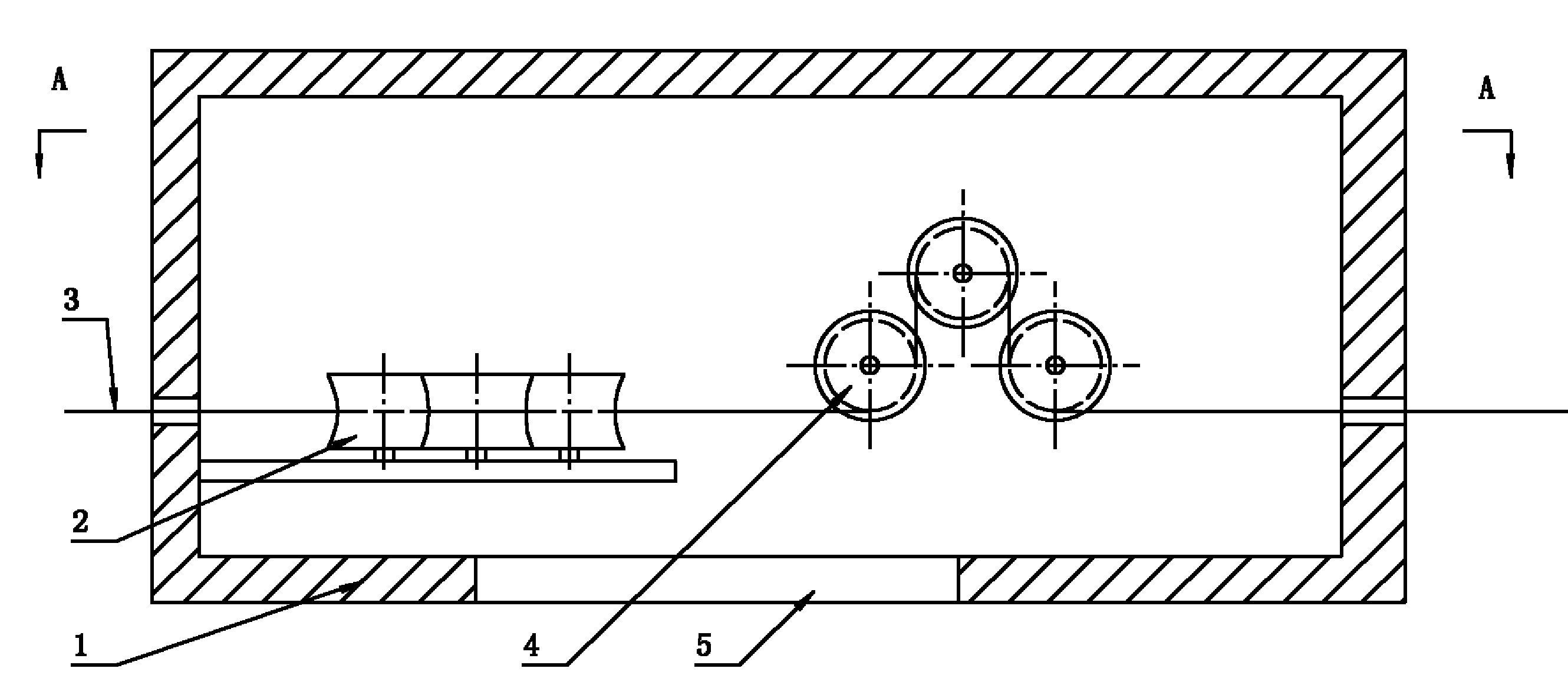

[0013] Remove the metal oxide scale of the welding wire to be drawn: the oxide scale is peeled off by passing the welding wire 3 to be drawn through a peeling machine, and the peeling machine is as follows: figure 1 and figure 2 As shown, the peeling machine has a group of longitudinal sheaves 2 vertically arranged on three axes installed in the casing 1. The relative positions of the three longitudinal sheaves 2 are arranged in the shape of "product" to form a group of longitudinal folding. Winding wheel group: In the casing 1, after the longitudinal winding of the wheel group, three horizontal sheaves 4 arranged horizontally on the axis are installed. The wheel set, the welding wire 3 to be pulled is successively bypassed in the peeling machine by the longitudinal folding wheel set formed by three longitudinal sheaves 2 and the transverse folded wheel set formed by three transverse sheaves 4 to make the oxide skin on the surface Detach after repeated bending; the detached...

Embodiment 2

[0020] Except for the following parameters, other parts of this embodiment are the same as in Embodiment 1: the process conditions of the electrolytic pickling step are that the moving speed of the welding wire to be drawn is 0.5 m / s, the surface current density of the welding wire to be drawn is 350A / d㎡, and the electrolysis The temperature of the liquid is controlled at 25-35°C. The weight ratio of the following components in the electrolyte is 1% sulfuric acid, 2% hydrochloric acid, 5% sodium sulfate, and 0.005% additives. The weight ratio of the following components in the additive is dodecane 80% sodium base benzene sulfonate, 5% alkylphenol polyoxyethylene ether, and the balance is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com