Method and device for rapid high-temperature heating of plates

A high-temperature heating and heating method technology, which is applied in the direction of measuring devices, heat treatment furnaces, and analytical materials, can solve the problems that the heating furnace occupies a large space, cannot reach a high temperature above 900°C, and is easy to be oxidized, and achieves a compact structure of the device. Easy to make, stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as Figure 5a , as shown in 5b and 5c, bend the induction coil 5 into a rectangular frame of 220*220*50mm to ensure the uniformity of heating, a total of 30 turns, and the specific parameters are shown in Table 1.

[0032] Table 1 Induction coil parameter list

[0033]

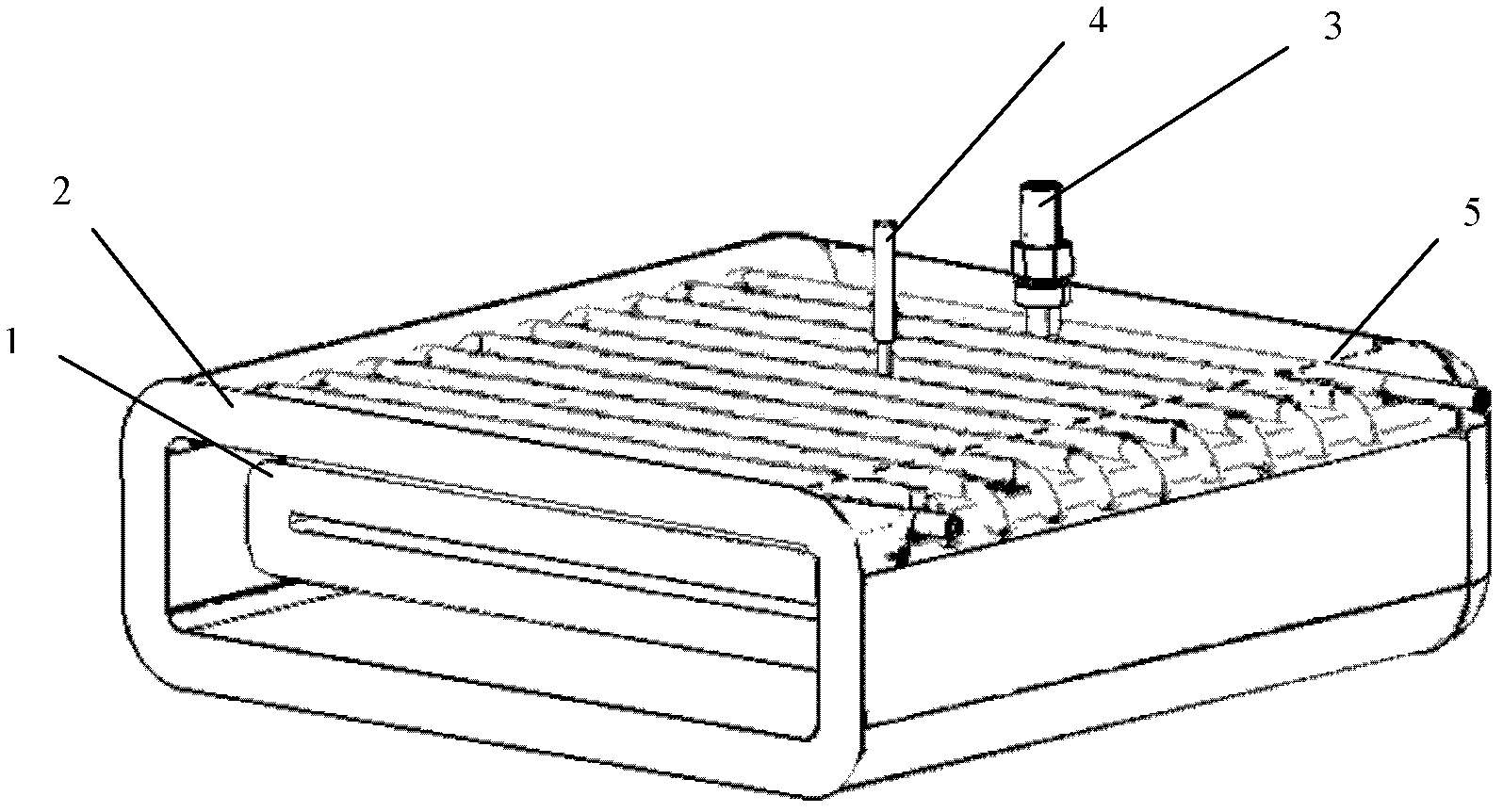

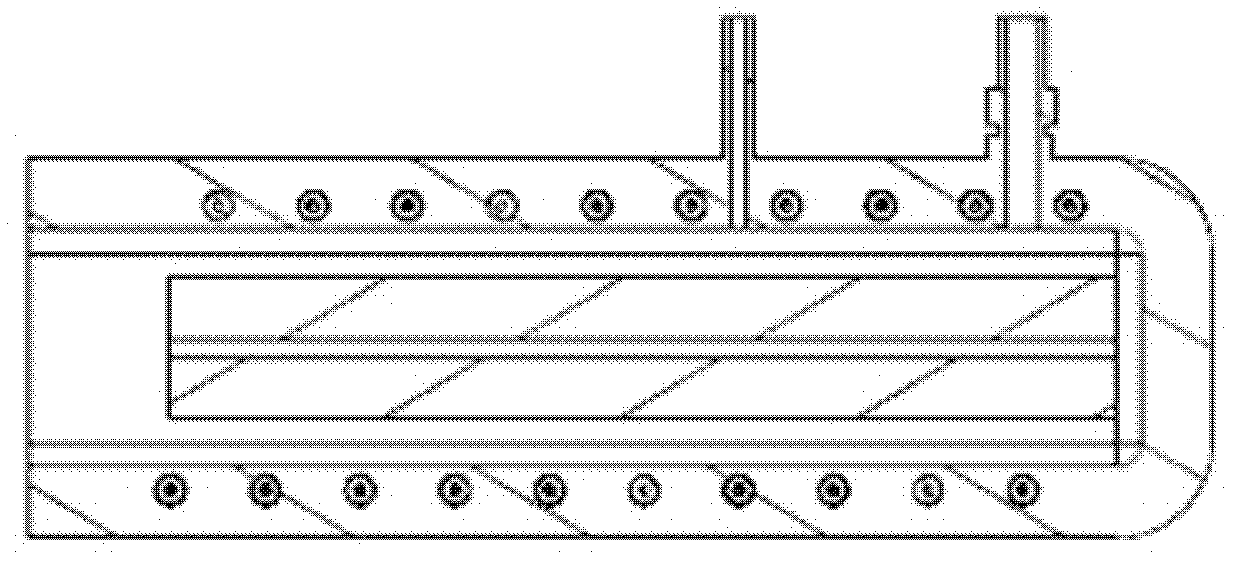

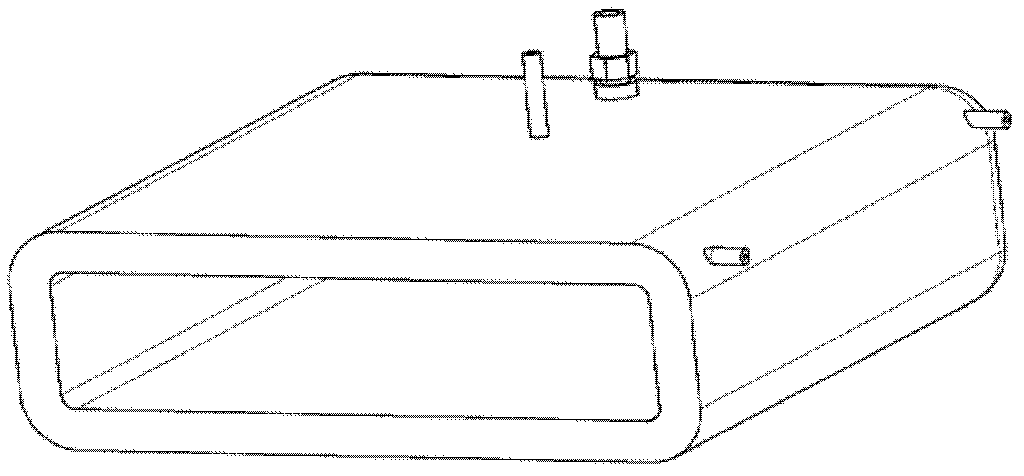

[0034] Such as Figure 1-4 As shown, the induction coil 5 bent into a rectangular frame is fixed and packaged with cement to form a box-shaped heating chamber with one side open, and the positions required for the installation of the protective gas charging port 3 and the thermocouple installation hole 4 are fixed. After the cement is cured , that is, the cement heating chamber 2 is formed. The graphite inner cavity 1 is placed in the center of the cement heating cavity 2, and a gap of 3 mm is left, which is fixed with cement slurry.

[0035] Pass the inert gas helium into the protective gas filling hole 3, drive away the air in the cement heating chamber 2, and prevent the sample from being ...

Embodiment 2

[0037] Such as Figure 5a , 5b, 5c, the induction coil 5 is bent into a rectangular frame of 500mm*500mm*80mm to ensure the uniformity of heating, a total of 80 turns.

[0038] Such as Figure 1-4 As shown, the induction coil 5 bent into a rectangular frame is fixed and packaged with cement to form a box-shaped heating chamber with one side open, and the positions required for the installation of the protective gas charging port 3 and the thermocouple installation hole 4 are fixed. After the cement is cured , that is, the cement heating chamber 2 is formed. The graphite inner cavity 1 is placed in the center of the cement heating cavity 2, and a gap of 8mm is left, and is fixed with cement slurry.

[0039]Pass the inert gas helium into the protective gas filling hole 3, drive away the air in the cement heating chamber 2, and prevent the sample from being over-oxidized at high temperature. Install it in the thermal couple installation hole 4, and connect the thermostat; conn...

Embodiment 3

[0041] Such as Figure 5a , As shown in 5b and 5c, the induction coil 5 is bent into a rectangular frame of 400mm*400mm*65mm to ensure the uniformity of heating, with a total of 60 turns.

[0042] Such as Figure 1-4 As shown, the induction coil 5 bent into a rectangular frame is fixed and packaged with cement to form a box-shaped heating chamber with one side open, and the positions required for the installation of the protective gas charging port 3 and the thermocouple installation hole 4 are fixed. After the cement is cured , that is, the cement heating chamber 2 is formed. The graphite inner cavity 1 is placed in the center of the cement heating cavity 2, and a gap of 5mm is left, and is fixed with cement slurry.

[0043] Pass the inert gas helium into the protective gas filling hole 3, drive away the air in the cement heating chamber 2, and prevent the sample from being over-oxidized at high temperature. Install it in the thermal couple installation hole 4, and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com