Method for constructing escherichia coli genetic engineering bacteria for producing fumaric acid

A technology of genetically engineered bacteria and Escherichia coli is applied in the field of constructing fumaric acid-producing Escherichia coli genetically engineered bacteria to achieve better and ideal results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

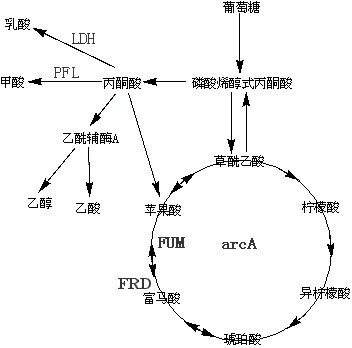

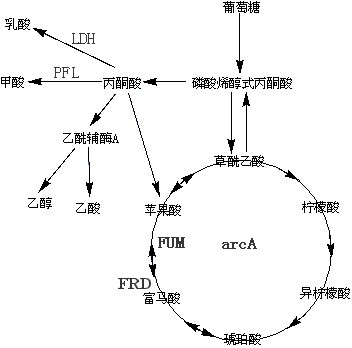

Method used

Image

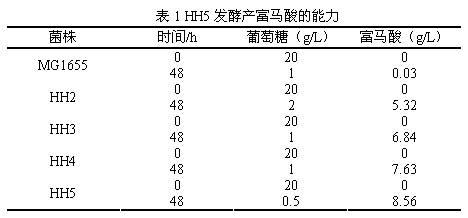

Examples

Embodiment 1

[0032] This example illustrates the use of RED recombination technology to knock out the starting strain parent E. coli Methods of encoding the TCA cycle fumarase (FUM) gene in MG1655.

[0033] 1. Using LB medium, culture at 37°C under aerobic conditions E. coli MG1655 to OD600=0.6, prepared to be electroporation competent.

[0034] 2. Introduce plasmid pKD46 into competent Escherichia coli, cultivate overnight at 30°C, inoculate into LB medium (containing ampicillin, 100 μg / L) the next day, cultivate at 30°C until OD=0.25, add 10 mM L-arabinose, induced plasmid pKD46 to express three proteins EXo, Bet and Gam at 37°C, and prepared competent cells again E. coli MG1655 1 .

[0035] 3. Using pKD3 with FRT sites on both sides and chloramphenicol resistance as a template, use a high-fidelity PCR amplification system, and design fumA Amplification primers for homologous fragments, amplified to obtain linear DNA homologous fragments. Similarly, combining various subunits...

Embodiment 2

[0051] This example describes the E. coli HH1 is the starting strain, using RED recombinant technology to knock out the protein gene (arcA) that inhibits the TCA cycle, so as to realize the normal opening of the TCA cycle under anaerobic conditions.

[0052] 1. Using LB medium, culture at 37°C under aerobic conditions E. coli From HH1 to OD600=0.6, it was prepared as a competent state for electroconversion.

[0053] 2. Introduce plasmid pKD46 into competent Escherichia coli, cultivate overnight at 30°C, inoculate into LB medium (containing ampicillin, 100 μg / L) the next day, cultivate at 30°C until OD=0.25, add 10 mM L-arabinose, induced plasmid pKD46 to express three proteins EXo, Bet and Gam at 37°C, and prepared competent cells again E. coli HH1 1 .

[0054] 2. Using pKD3 with FRT sites on both sides and chloramphenicol resistance as a template, use a high-fidelity PCR amplification system, and design amplification primers with FRD homologous fragments at both ends...

Embodiment 3

[0062] This embodiment is an optimized implementation scheme on the basis of embodiment 2, illustrating the following E. coli HH2 is the starting strain, using RED recombinant technology to knock out a subunit of fumarate reductase FRD wxya , to achieve the destruction of FRD and block the conversion of fumaric acid to succinic acid.

[0063] 1. Using LB medium, culture at 37°C under aerobic conditions E. coli HH2 to OD600=0.6, prepared to be electroporation competent.

[0064] 2. Introduce plasmid pKD46 into competent Escherichia coli, cultivate overnight at 30°C, inoculate into LB medium (containing ampicillin, 100 μg / L) the next day, cultivate at 30°C until OD=0.25, add 10 mM L-arabinose, induced plasmid pKD46 to express three proteins EXo, Bet and Gam at 37°C, and prepared competent cells again E. coli HH2 1 .

[0065] 2. Using pKD3 with FRT sites on both sides and chloramphenicol resistance as a template, use a high-fidelity PCR amplification system, and design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com