Water seal device suitable for high-temperature and high-thermal environment of dry quenching coke furnace

A technology of dry quenching coke oven and water sealing device, applied in coke oven, coke cooling, petroleum industry and other directions, can solve problems such as maintenance, replacement construction difficulties, water seal bursting, safety hazards and other problems, and achieve significant social and economic benefits. Benefit, safety of maintenance and replacement process, excellent sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

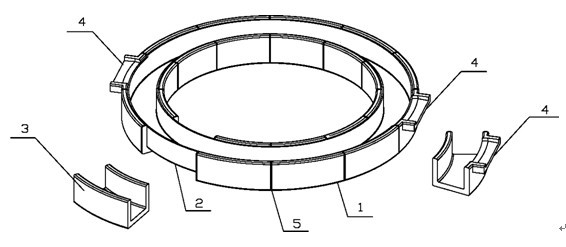

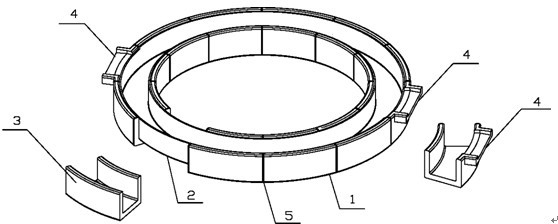

[0013] The invention consists of a permanent refractory outer tank 1 and a stainless steel inner tank 2 .

[0014] As shown in the figure, the permanent refractory outer tank 1 is formed by a plurality of arc-shaped groove bricks 3 and arc-shaped groove bricks 4 with overflow weirs bonded by refractory mud 5 to form an annular groove. The curved groove brick 3 and the curved groove brick 4 with an overflow weir are fired from refractory materials with excellent high temperature resistance and thermal shock resistance. The arc-shaped groove bricks 4 with overflow weirs can be arranged at any position on the circumference of the permanent refractory outer groove 1, and one piece or multiple pieces can be arranged.

[0015] The figure shows that the stainless steel inner tank 2 is punched or welded into an annular groove by a thin heat-resistant stainless steel plate, the stainless steel inner tank 2 is embedded in the permanent refractory outer tank 1, and the outer wall size of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com