Method for preparing sorbitol polyether polyol

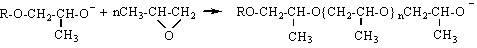

A technology of sorbitol polyether and polyether polyol, which is applied in the directions of ether preparation, alkylene oxide preparation of ether, organic chemistry, etc. In order to improve the uniformity of mixing, improve fluidity, and improve product performance and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

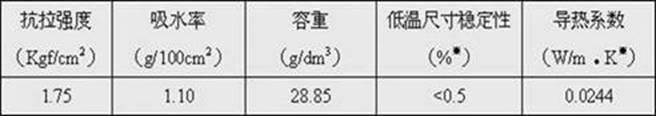

Examples

Embodiment 1

[0036] ( The molar ratio of propylene oxide to crystalline sorbitol is 12:1)

[0037]Add 400g of crystalline sorbitol, 1550g of propylene oxide, 6.0g of catalyst and 4.0g of regulator into the reactor, cover and tighten the screws, then replace the air in the reactor with nitrogen for 3 times, remove the oxygen from the reactor, and then use nitrogen Pressurize to 0.15 Mpa, heat, start the stirring device, heat preservation reaction for 7 hours when the temperature rises to 95°C, and the reaction ends after the pressure drops to a constant value, turn on the cooling water to cool to room temperature, open the cover and discharge to obtain crude sorbitol polymer ether polyols.

[0038] Add phosphoric acid with a concentration of 10% to the crude sorbitol polyether polyol for neutralization reaction, neutralize to pH 7.0; heat, vacuumize and degas at 45~55°C, control the vacuum degree to 0.001 Mpa, degas for 60min ; and then in the state of stirring, add activated carbon to ca...

Embodiment 2

[0041] ( The molar ratio of propylene oxide to crystalline sorbitol is 15:1)

[0042] Add 1kg of crystalline sorbitol, 4.78kg of propylene oxide, 23g of catalyst and 23g of regulator into the reactor, cover and tighten the screws, then replace the air in the reactor with nitrogen for 4 times, remove the oxygen from the reactor, and then fill it with nitrogen. Press down to 0.15 Mpa, heat, start the stirring device, heat preservation reaction for 8 hours when the temperature rises to 95°C, and the reaction ends after the pressure drops to a constant value, turn on the cooling water to cool to room temperature, open the cover and discharge to obtain crude sorbitan polyether Polyol.

[0043] Add 99% solid oxalic acid to the crude sorbitol polyether polyol for neutralization reaction, neutralize to pH 7.1; heat, vacuumize and degas at 45~50°C, control the vacuum degree to 0.001 Mpa, degas for 80min ; and then in the state of stirring, add activated carbon to carry out the adsorp...

Embodiment 3

[0046] ( The molar ratio of propylene oxide to crystalline sorbitol is 13:1)

[0047] Add 800g of crystalline sorbitol, 3316g of propylene oxide, 14.5g of catalyst and 12.3g of regulator into the reactor, cover and tighten the screws, then replace the air in the reactor with nitrogen for 2 times, remove the oxygen from the reactor, and then use nitrogen Pressurize to 0.18Mpa, heat, start the stirring device, heat preservation reaction for 8 hours when the temperature rises to 90°C, the reaction ends after the pressure drops to a constant value, turn on the cooling water to cool to room temperature, open the cover and discharge to obtain crude sorbitol polymer ether polyols.

[0048] Add phosphoric acid with a concentration of 10% to the crude sorbitol polyether polyol for neutralization reaction, and neutralize to a pH value of 6.9; heat, vacuumize and degas at 50~55°C, control the vacuum degree to 0.001 Mpa, and degas for 40 minutes ; and then in the state of stirring, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap