Method for controlling formation quantity of bromate in ozone oxidized water treatment process by TiO2

A technology of ozone oxidation and nano-titanium dioxide, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of reducing organic matter, high safety and reliability of drinking water, and increasing the production potential of total organic bromine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

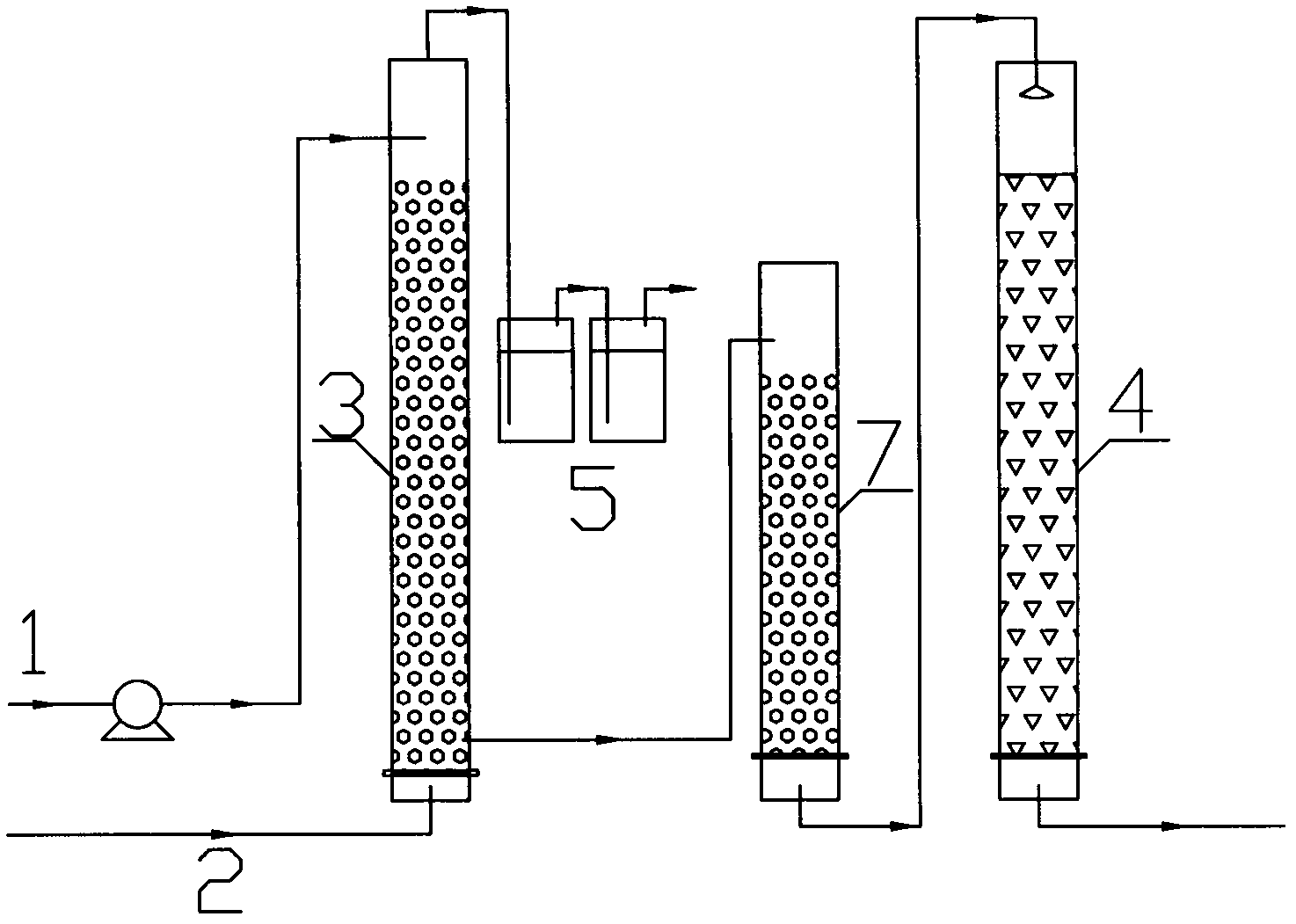

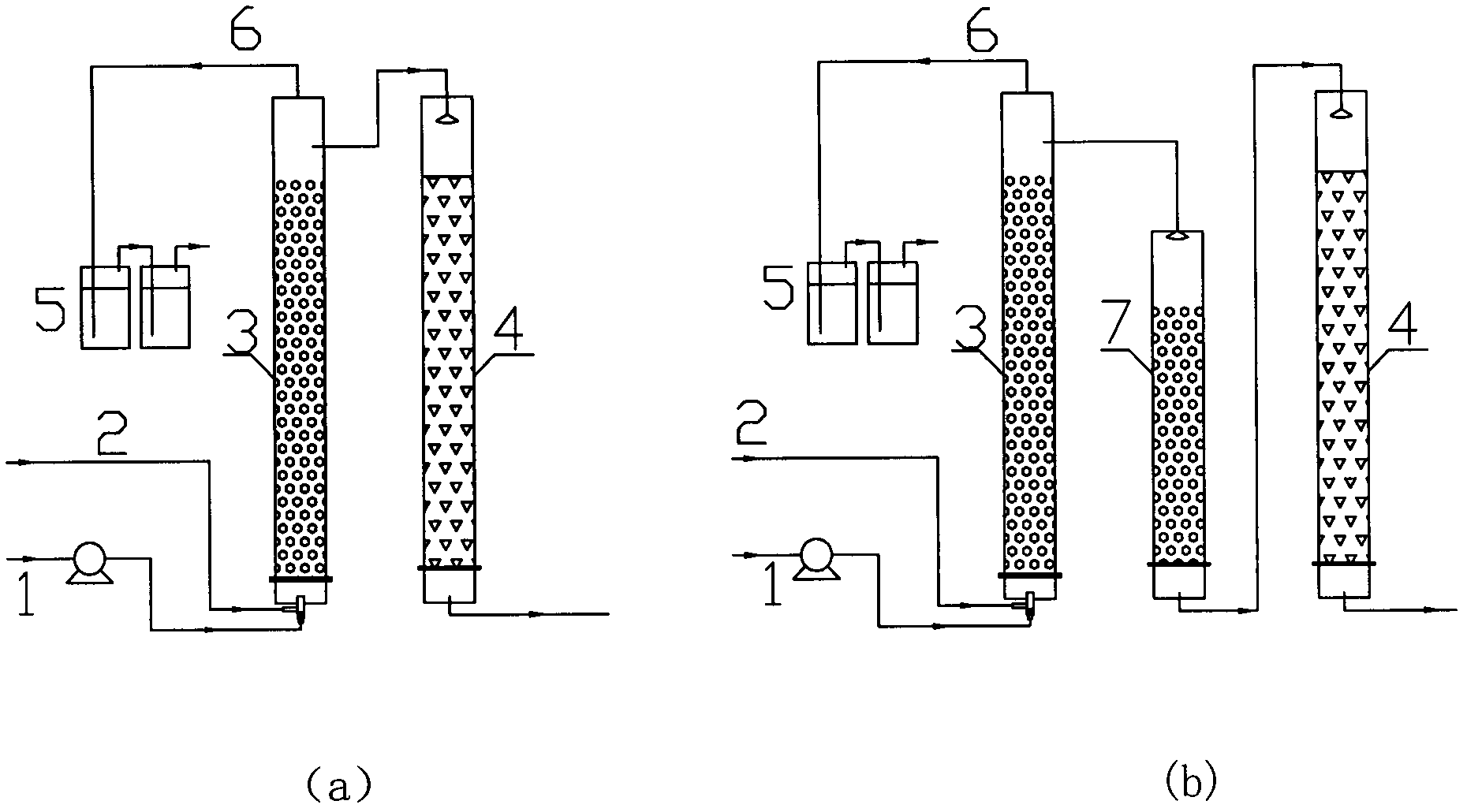

[0016] Specific implementation mode 1: The sinking water after coagulation and precipitation treatment by the conventional treatment process enters the catalytic bed filled with supported nano-metal oxides for catalytic ozone oxidation, the ozone enters from the bottom of the catalytic bed, and the sinking water flows from the catalytic bed The part near the top enters, the ozone dosage is: 0.4-3.5mgO 3 / mgDOC, the catalytic contact time is: 10-20min; the effluent enters the sand filter / activated carbon filter for further filtration, then adds chlorine (chloramine) for disinfection, and then sends it to the user. See attached for specific process figure 1 .

specific Embodiment approach 2

[0017] Specific implementation mode 2: Different from the above-mentioned implementation method 1, the water after sinking enters the first-stage ozone catalytic oxidation bed to carry out the ozone oxidation reaction for 5-15 minutes, and the water still containing ozone from the ozone catalytic oxidation bed enters the interior to fill with a load In the second-stage catalyst bed of the type nanometer metal oxide catalyst, the time for controlling the second-stage catalytic oxidation is 5-10 minutes. Other steps and process conditions are the same as the above method. See attached for specific process figure 2 .

specific Embodiment approach 3

[0018] Specific implementation method three: different from the above-mentioned implementation methods one and two, when the sinking water enters the catalytic bed filled with loaded nano-metal oxides for catalytic ozonation, the sinking water is positively discharged from the bottom of the catalytic bed (or catalytic tank). Enter from below or enter through the bottom water inlet of the ejector (the specific location is shown in the attached image 3 As shown), ozone enters from the side of the bottom of the catalytic bed through the gas distribution plate or jet device and quickly contacts with the sinking water, and immediately catalyzes ozone oxidation through the catalyst. Other embodiments and process conditions are the same as those of the first and second methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com