Full-automatic multifunctional deburring machine

A deburring machine and multi-functional technology, applied in the field of mechanical equipment, can solve the problems of low automation, difficult operation, and low production quality, and achieve the effect of liberating heavy physical labor, relaxing grinding work, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

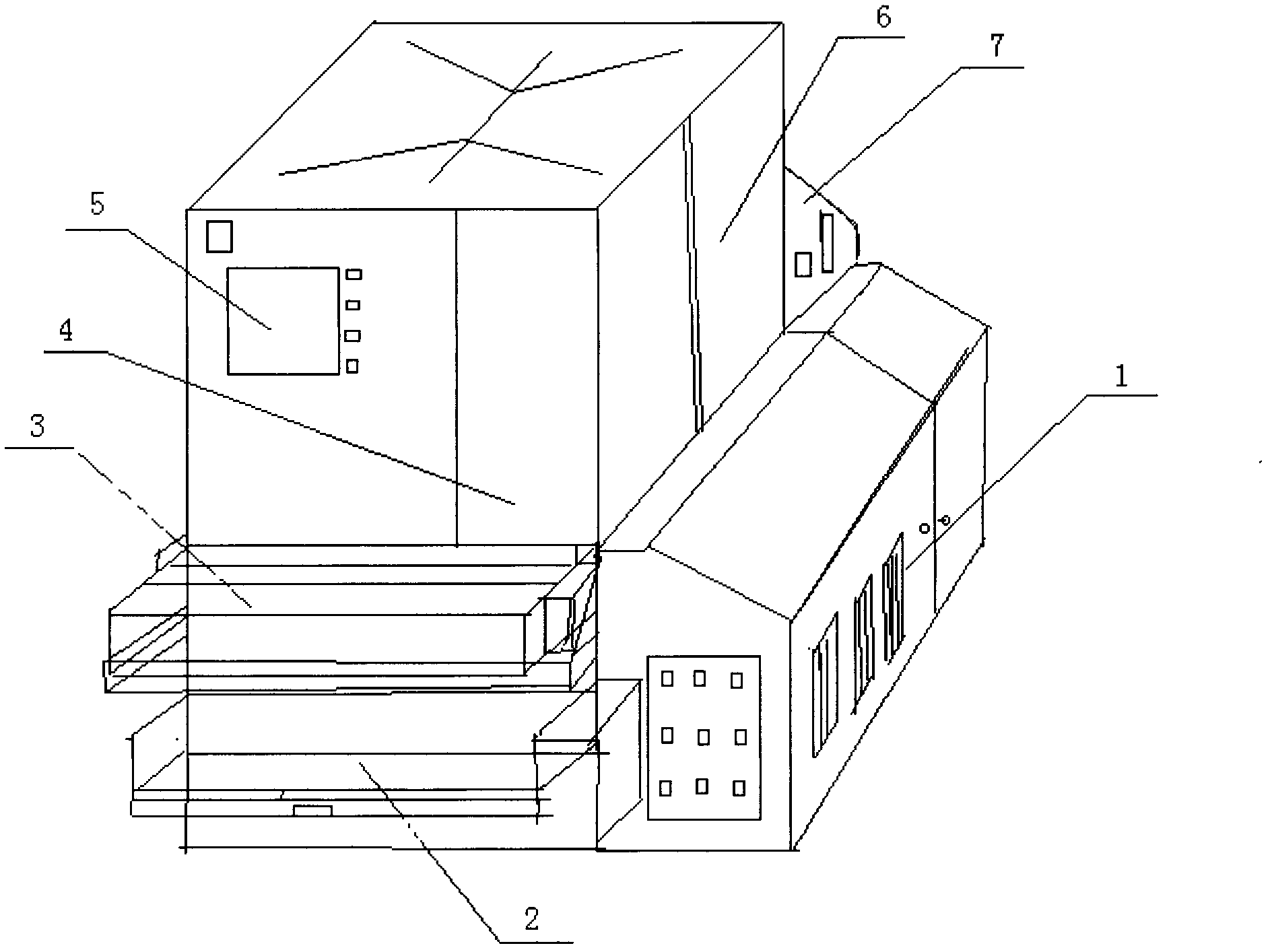

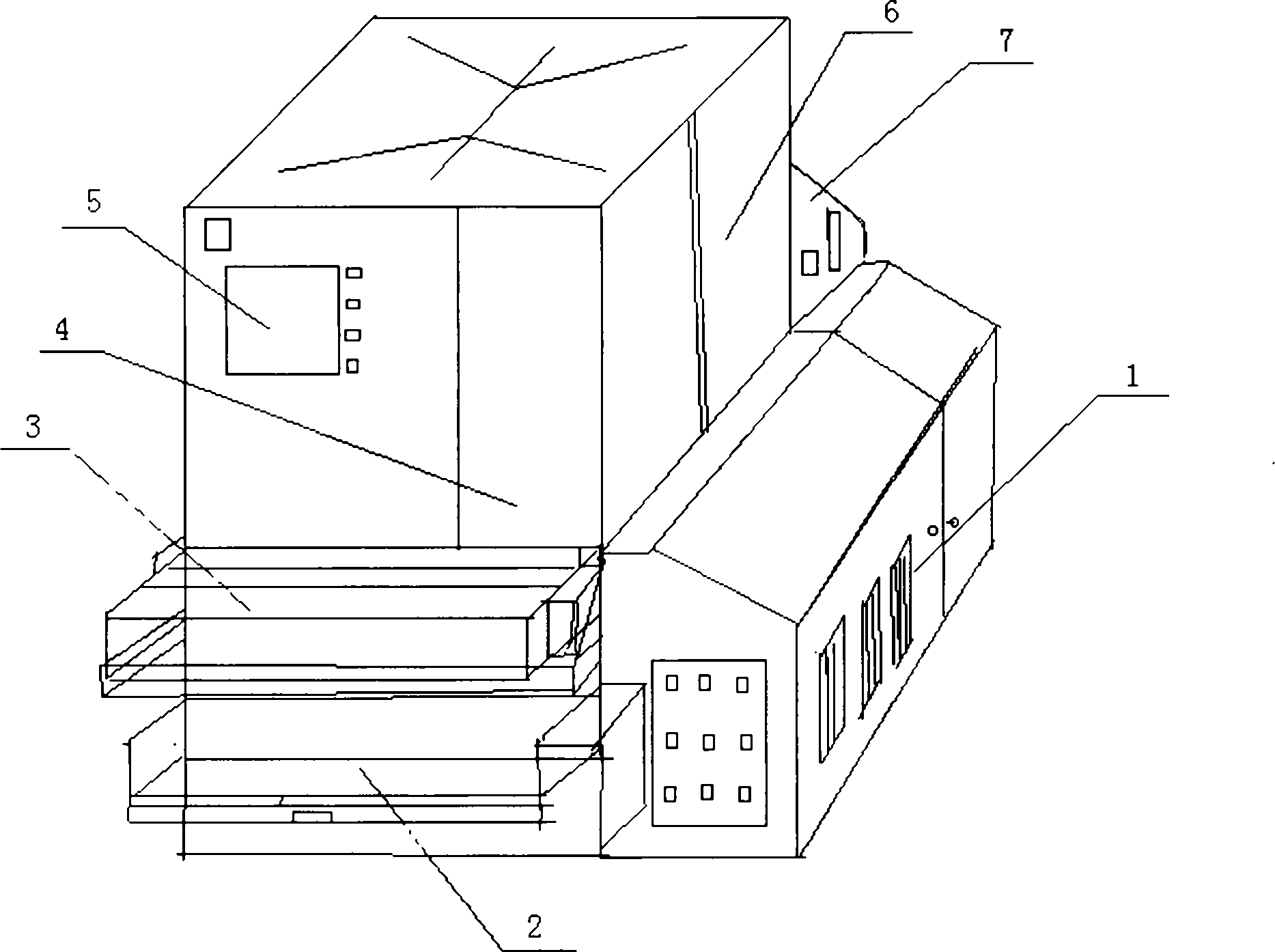

[0015] The technical solution of the present invention will be further specifically described below in conjunction with the accompanying drawings.

[0016] refer to figure 1 with figure 2 As shown, the present invention includes a processing control cabinet 4, a touch screen control panel 5 is provided on the front of the processing control cabinet 4, a sheet metal protection door 6 is provided on the side of the processing control cabinet 4, and a sheet metal protection door 6 is provided on the side of the processing control cabinet 4. A variable frequency motor drive mechanism 1 is provided under the door 6, a workpiece input conveying device 3 and a cutting fluid filtering device 2 are respectively provided under the touch screen control panel 5, and a workpiece air-drying device is provided on the side of the sheet metal protection door 6. The outlet device 7, the cutting fluid filter device 2 and the workpiece air-drying outlet device 7 are connected through a transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com