Processing method of miniature spherical or aspherical lens array

A kind of aspheric lens and miniature technology, which is applied in the field of optical device processing, can solve the problems such as difficult to process micro and array lenses, and achieve the effect of solving difficult to process micro and array lenses, easy to popularize and apply, and easy to process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In the method, figure 1 It is used for processing the optical glass substrate 10 of the microlens array, and its upper surface needs to be polished in advance to meet the requirements of the optical mirror surface.

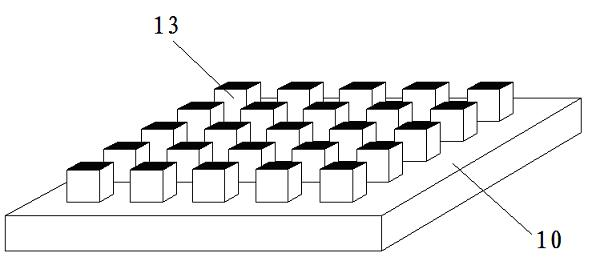

[0030] according to figure 2 Use a grinding wheel 20 with multiple grooves to grind two groups of mutually perpendicular grooves 11 on the glass surface, and form some square columns between the two groups of grooves, and these regularly arranged square columns form a square column arrays, such as image 3 shown.

[0031] Figure 4 The ultrasonic grinding head 51 shown is connected with the ultrasonic horn 52, and the ultrasonic grinding head 51 is composed of a plurality of cylindrical pits 31, whose shape is shown in Figure 5 . Use this grinding head to grind the square cylinder into a cylinder, such as Figure 7 , Figure 8 Shown is an ultrasonic micro grinding head 30 with a single pit and the processed micro cylinder 12. The depth of the pit ...

Embodiment 2

[0035] Process a miniature non-linear optical lens array, the overall dimensions of the device are 32mm×32mm×4.5mm, the height of a single lens micro cylinder 14 is 2.5mm, and the diameter of the upper circle of the micro cylinder 12 is 2.6mm and the diameter of the lower circle is 3.0mm The non-linear change, the lens arrangement is 5×5 array, and the lens material is G9 optical glass.

[0036] The production process is divided into the following steps:

[0037] 1. (1) Design and process the ultrasonic four-hole grinding head 51, the depth of the cylindrical pit is 3.5mm, the diameter is 3.1mm, and the distance between adjacent pit sides is 3.0mm. The material used for the grinding head is tool steel. (2) Design and process ultrasonic single-hole grinding head 30, refer to Figure 8 In 31, the diameter of the large circle of the pit is 3.0mm, and the diameter of the small circle is 2.7mm. The material is tool steel. (3) Refer to Figure 9 Design and process the polishing...

Embodiment 3

[0043]Process a miniature spherical optical lens array, the overall dimensions of the device are 23mm×20mm×4.5mm, the height of a single lens micro cylinder 14 is 1.2mm, the diameter of the upper circle of the micro cylinder 12 is 1.9mm, and the diameter of the lower circle is 2.4mm, The side of the micro-pillar is a spherical surface with a diameter of 2.4mm, the lenses are arranged in a 5×4 array, and the lens material is G9 optical glass. Process relevant abrasive tools according to the above parameters:

[0044] (1) Design and process the ultrasonic four-hole grinding head 51, the depth of the cylindrical pit 31 is 1.6mm, the diameter is 2.6mm, and the distance between adjacent pit sides is 2.8mm; the material used for the grinding head is tool steel.

[0045] 2) Design and process ultrasonic single-hole grinding head 30, refer to Figure 8 Among them, the diameter of the large circle of the pit 31 is 2.5mm, and the diameter of the small circle is 2.0mm; the material is t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com