Method for directly machining turbine blade air film irregular holes through laser

A turbine blade and laser direct technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of hole position and angle deviation, poor surface shape consistency of special-shaped holes, and low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments:

[0028] See attached Figure 3-7 As shown, the method for directly processing the special-shaped hole of the turbine blade air film by this kind of laser is characterized in that: the special-shaped hole processed by the method is an oblique hole, and the shape of the entrance (1) of the special-shaped hole on the blade surface is the two waists of an equilateral trapezoid (4) It is tangent to the cylindrical through hole (2), and the three-dimensional shape of the special-shaped hole is a funnel-shaped trapezoid (large on the top and small on the bottom) and the cylindrical through hole (2) is connected with a smooth transition inside, and the hole exit is still for round holes.

[0029] The steps of this method are:

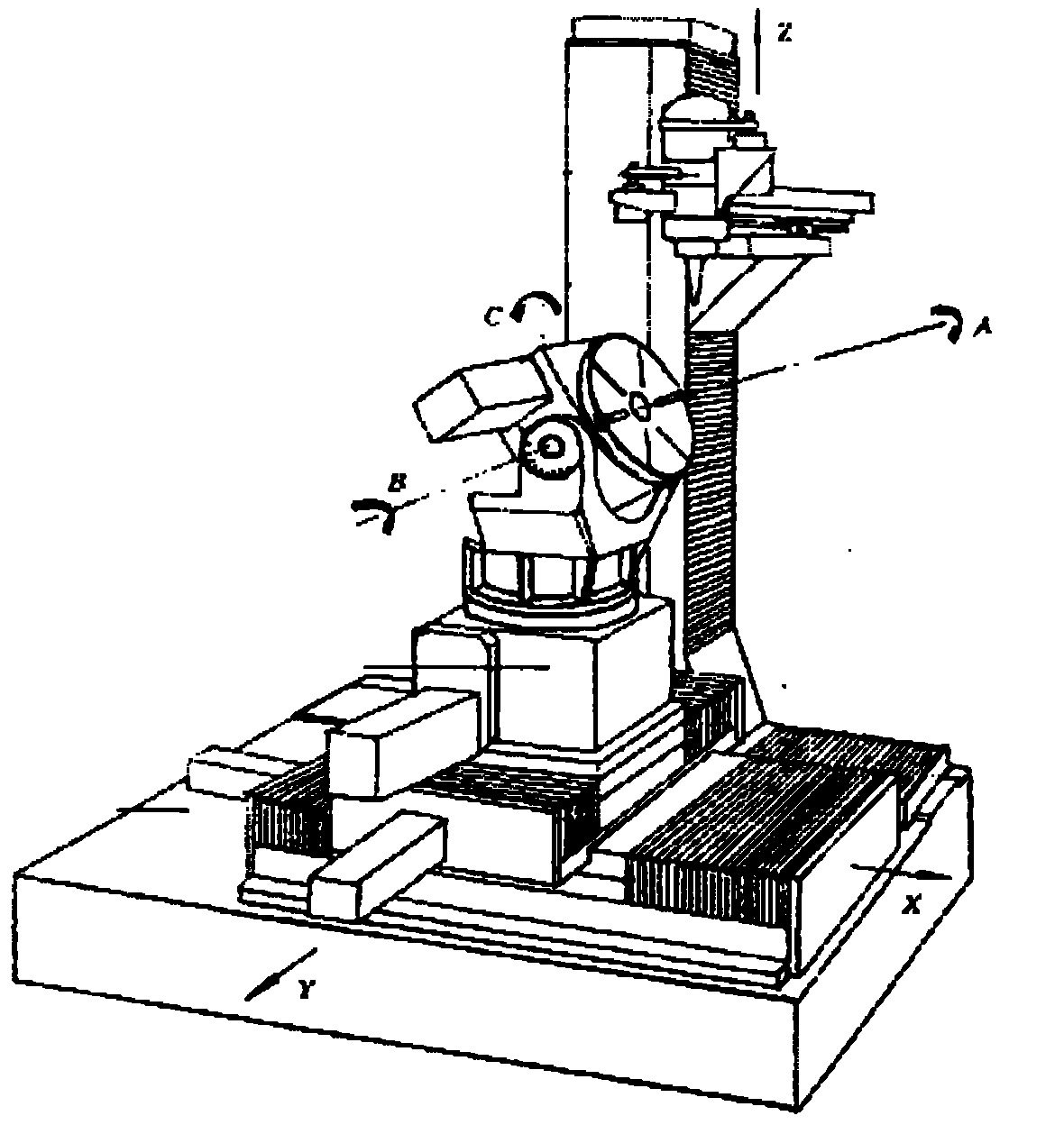

[0030] (1) An eight-axis five-link CNC laser processing machine tool equipped with a two-dimensional numer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com