Vacuum centrifugal casting method and device

A technology of vacuum centrifugation and evacuation, which is applied in the field of casting methods and devices, can solve the problems of difficulty in sealing the joint of a sealing cover, large air extraction volume, and difficulty in improving the degree of vacuum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

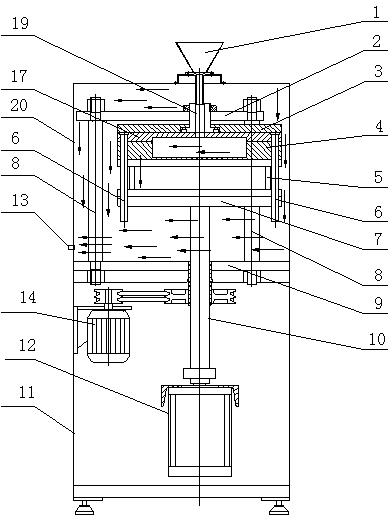

[0011] Depend on figure 1 It can be seen that the upper part of the frame 11 is provided with a sealing cover 20, and the sealing cover 20 is provided with an air extraction joint 13, and the forming mechanism composed of the connecting seat 5, the lower mold 4, the upper mold 17 and the upper mold mounting seat 3 is arranged on the sealing cover 20. Inside. During work, because the inner space of the sealing cover 20 is too large, the amount of air extraction is large, figure 1 The middle arrow shows the direction of the air, and it is difficult to seal, which makes it difficult to increase the vacuum degree. At the same time, due to the existence of the sealing cover 20, the runner 19 is longer, the temperature drops too fast during the pouring process, and the pouring temperature is not easy to control, especially for pouring small castings.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com