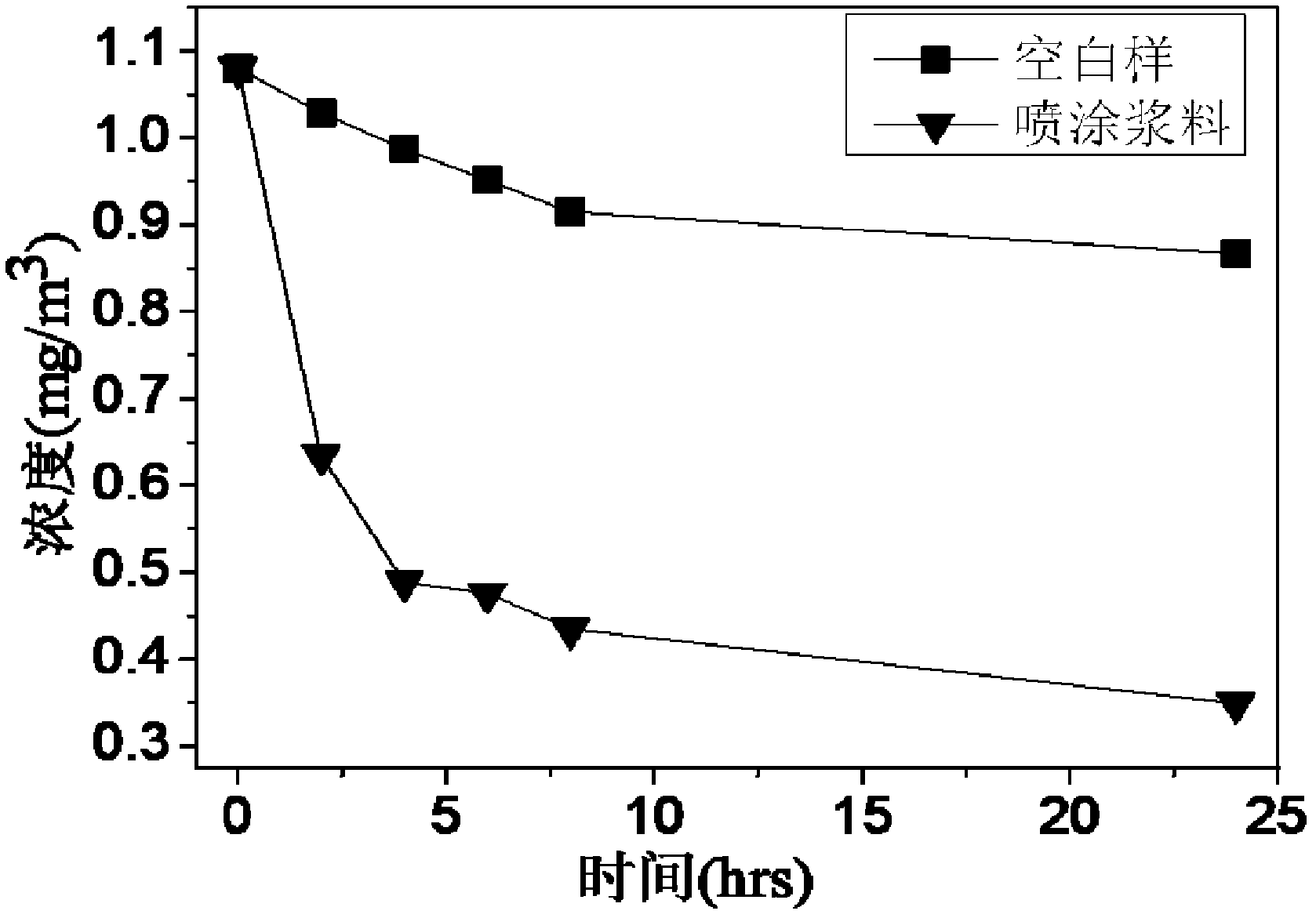

Preparation method of visible light response water-based photocatalytic spray coating slurry

A visible light and photocatalytic technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of inapplicability, limited application range, poor stability, etc., and achieve good photocatalytic performance and promote Popular application, excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] First, 800 parts by weight of water, 0.1 parts by weight of sodium disilicate as a wetting and dispersing agent, and 10 parts by weight of bentonite as a thickening and dispersing agent were stirred at high speed for 30 minutes to obtain a dispersion, and then the chromium-nitrogen co-doped nano-titanium dioxide powder was weighed according to 4 The proportion of parts by weight is dispersed in a certain amount of pre-stirred dispersion liquid under the condition of high-speed stirring to obtain a mixture. Put the above-mentioned mixture into a sand mill for 2 hours, then add 50 parts by weight of alumina sol, an effective bonding film-forming component, continue sanding for 30 minutes, and then carry out degassing and stirring for 1 hour to obtain visible light response nano-titanium dioxide photocatalytic spraying for spraying. slurry.

Embodiment 2

[0023] First, 1000 parts by weight of water, 1 part by weight of sodium hexametaphosphate as a wetting and dispersing agent, and 30 parts by weight of sepiolite as a thickening and dispersing agent were stirred at high speed for 30 minutes to obtain a dispersion. The iron-nitrogen co-doped nano-titanium dioxide powder responding to visible light is weighed and dispersed in a certain amount of pre-stirred dispersion liquid under the condition of high-speed stirring in a proportion of 300 parts by weight to obtain a mixture. Put the above-mentioned mixture into a sand mill for 12 hours, then add 200 parts by weight of silica sol, an effective bonding film-forming component, continue sanding for 30 minutes, and then carry out defoaming and stirring for 1 hour to obtain visible light-responsive nano-titanium dioxide photocatalytic spraying for spraying. slurry.

Embodiment 3

[0025] First, 900 parts by weight of water, 3 parts by weight of wetting and dispersing agent (sodium disilicate: trisodium phosphate = 1:1), 60 parts by weight of thickening and dispersing agent (bentonite:: hectorite = 1:2) were mixed at high speed After stirring for 30 min, a dispersion was obtained. The chromium-doped nano-titanium dioxide powder that responds to visible light is weighed and dispersed in a certain amount of pre-stirred dispersion liquid under the condition of high-speed stirring in a proportion of 1000 parts by weight to obtain a mixture. Put the above mixture into a sand mill for 12 hours, then add 300 parts by weight of effective bonding and film-forming components (alumina sol: titanium dioxide sol = 1:1), continue sanding for 30 minutes, then defoam and stir for 1 hour to obtain Visible light-responsive nano-titanium dioxide photocatalytic spray coating slurry for spraying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com