Modified expanded perlite for treating low-concentration ammonia-nitrogen wastewater and wastewater treatment method

A technology of expanded perlite and low-concentration ammonia-nitrogen, which is applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of difficult treatment and cost of ammonia-nitrogen wastewater, and achieve improved adsorption efficiency and selectivity, strong The effect of ion exchange capacity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1 expanded perlite chemical modification

[0018] Put into 5% (w / w) sulfuric acid solution activation 0.5 hour through the expanded perlite 500 grams of drying and crossing 60 mesh sieves, put into saturated copper salt (copper sulfate, cupric chloride, Copper nitrate, etc.) solution, the soaking time is controlled at about 0.5-1.0 hours, and the dosage of expanded perlite is limited to be completely submerged in the copper salt saturated solution. Finally, it is filtered out and dried at 105±5°C to obtain the modified expanded perlite product.

Embodiment 2

[0019] Embodiment 2 wastewater treatment process

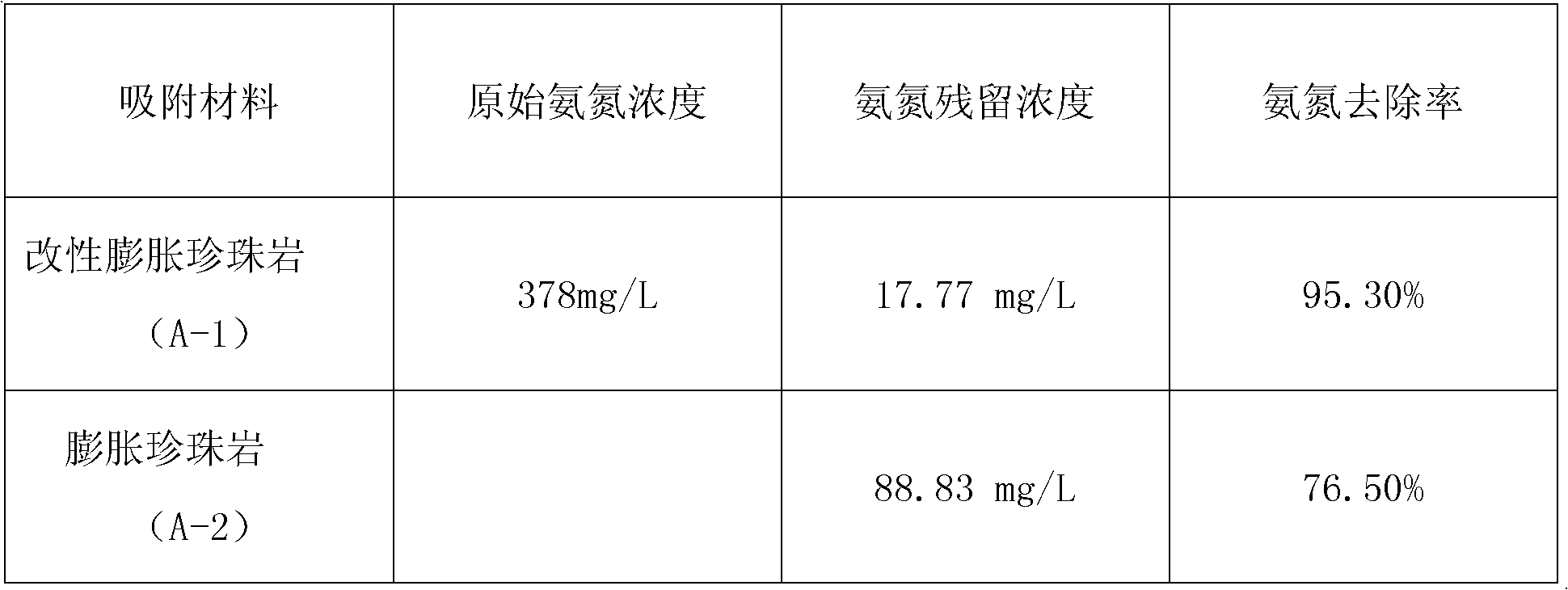

[0020] Using the fixed bed reaction method, 500 grams of the modified expanded perlite prepared in Example 1 and 500 grams of the unmodified expanded perlite were put into the adsorption reaction columns A-1 and A with upper and lower water inlets and outlets respectively. In -2, fill in. Adjust the pH value of the wastewater with an ammonia nitrogen content of 378mg / L to 7-9. Then take 3000ml of the waste water and introduce them into two adsorption columns respectively. The flow of water is controlled at 0.81m / h, and the residual ammonia nitrogen value in the effluent is measured. The treatment results are shown in Table 1.

[0021] Table 1 Residual ammonia nitrogen value in effluent

[0022]

[0023] The results show that the ability of the expanded perlite to remove ammonia nitrogen after modification has been significantly improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com