Method for extracting common macrocarpium fruit total glycoside and application of common macrocarpium fruit total glycoside to preparation of hypoxia tolerant medicines

An extraction method, the technology of cornus officinalis, applied in the field of plant materials, can solve the problems of heart and brain hypoxia and other problems that have not been seen in the total glycosides of cornus officinalis, and achieve the effect of improving the ability of patient brain hypoxia, high utilization rate of raw materials, and promoting hypoxia resistance and adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Taking Cornus officinalis fresh fruit extract Cornus officinalis dry medicinal material powder 100g as an example, the raw materials used and its extraction method are as follows:

[0029] 1. Boiling

[0030] Put the fresh fruit of Cornus officinalis into boiling water until submerged, cook in boiling water for 10-15 minutes, take it out and cool for a while, squeeze out the core by hand, dry the pulp at 40°C, crush it, and pass through a 20-mesh sieve to obtain the medicinal material of Cornus officinalis powder.

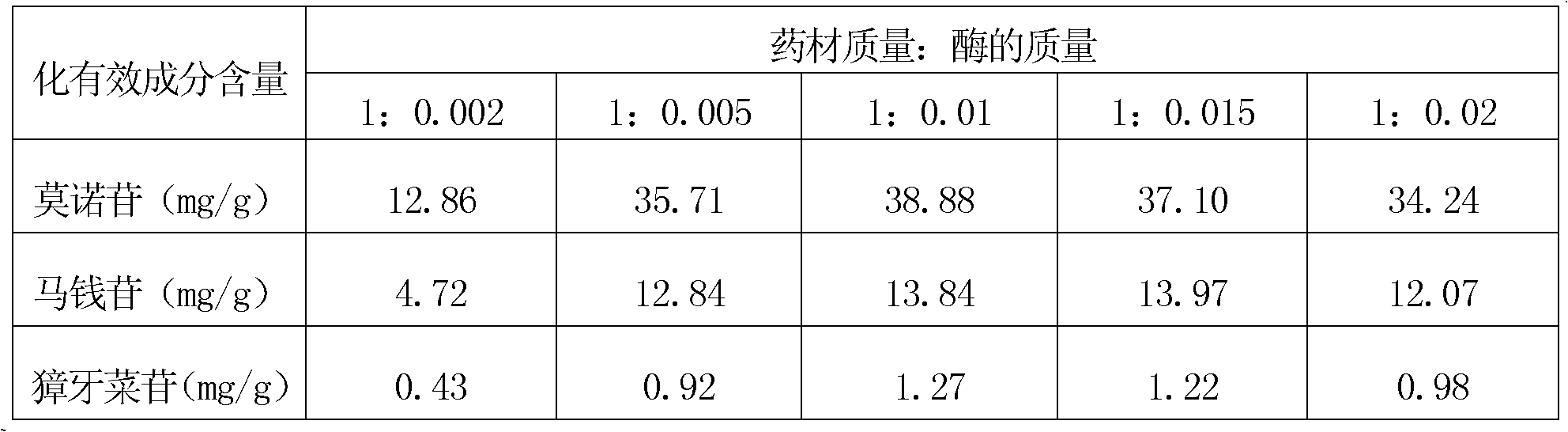

[0031] 2. Enzymatic extraction

[0032] Take 100g of dogwood medicinal material powder, add 2 to 4 times of water to swell, then add 1g of amygdala, the model of amygdala is M0034-1, and amygdala is a commodity sold in the market, sold by Shanghai Kexing Trading Co., Ltd. Adjust the pH value to 4.5 with glacial acetic acid, perform enzymolysis at a constant temperature of 50°C for 4 hours, add ethanol equal in mass to water to terminate the enzymolysis, add...

Embodiment 2

[0036] Taking Cornus officinalis fresh fruit extract Cornus officinalis dry medicinal material powder 100g as an example, the raw materials used and its extraction method are as follows:

[0037] In step 2 of enzymatic hydrolysis and extraction, take 100g of Cornus officinalis medicinal material powder, add 2 to 4 times of water to swell, then add 0.5g of amygdalinase, adjust the pH value to 4 with glacial acetic acid, enzymolyze at a constant temperature of 45°C for 6 hours, add water Equal mass of ethanol, stop enzymolysis, add water until the mass fraction of ethanol is 25% to 27%, use ultrasonic wave with a frequency of 25kHz and a power of 300W to extract for 30 to 40 minutes, pour out the supernatant; The ratio of liquid to material is 12 to 16 times, and the mass fraction is 25% to 27% of the ethanol aqueous solution to extract once, vacuum filtration, combined two extracts, and concentrated under reduced pressure to the extract with a relative density of 1.20 to obtain ...

Embodiment 3

[0040] Taking Cornus officinalis fresh fruit extract Cornus officinalis dry medicinal material powder 100g as an example, the raw materials used and its extraction method are as follows:

[0041]In step 2 of enzymatic hydrolysis and extraction, take 100g of Cornus officinalis medicinal powder, add 2 to 4 times of water to swell, then add 1.5g of amygdalinase, adjust the pH value to 4.5 with glacial acetic acid, enzymolyze at a constant temperature of 50C for 4 hours, add water, etc. quality ethanol, stop enzymolysis, add water until the mass fraction of ethanol is 25% to 27%, use ultrasonic wave with a frequency of 25kHz and a power of 300W to extract for 30 to 40 minutes, pour out the supernatant; Ratio of 12 to 16 times, the mass fraction of 25% to 27% ethanol aqueous solution is extracted once, vacuum filtration, combined two extracts, concentrated under reduced pressure to an extract with a relative density of 1.20, to obtain the ethanol extract of Cornus officinalis .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com