Black raspberry beverage and making method thereof

A production method and technology of black raspberries, which are applied in the field of food processing, can solve the problems affecting unique flavor, damage and loss of nutrients such as vitamins, amino acids, minerals, and easy loss of volatile aroma substances, so as to maintain flavor and function. Characteristics, significant effect on the balance of human nutrient intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

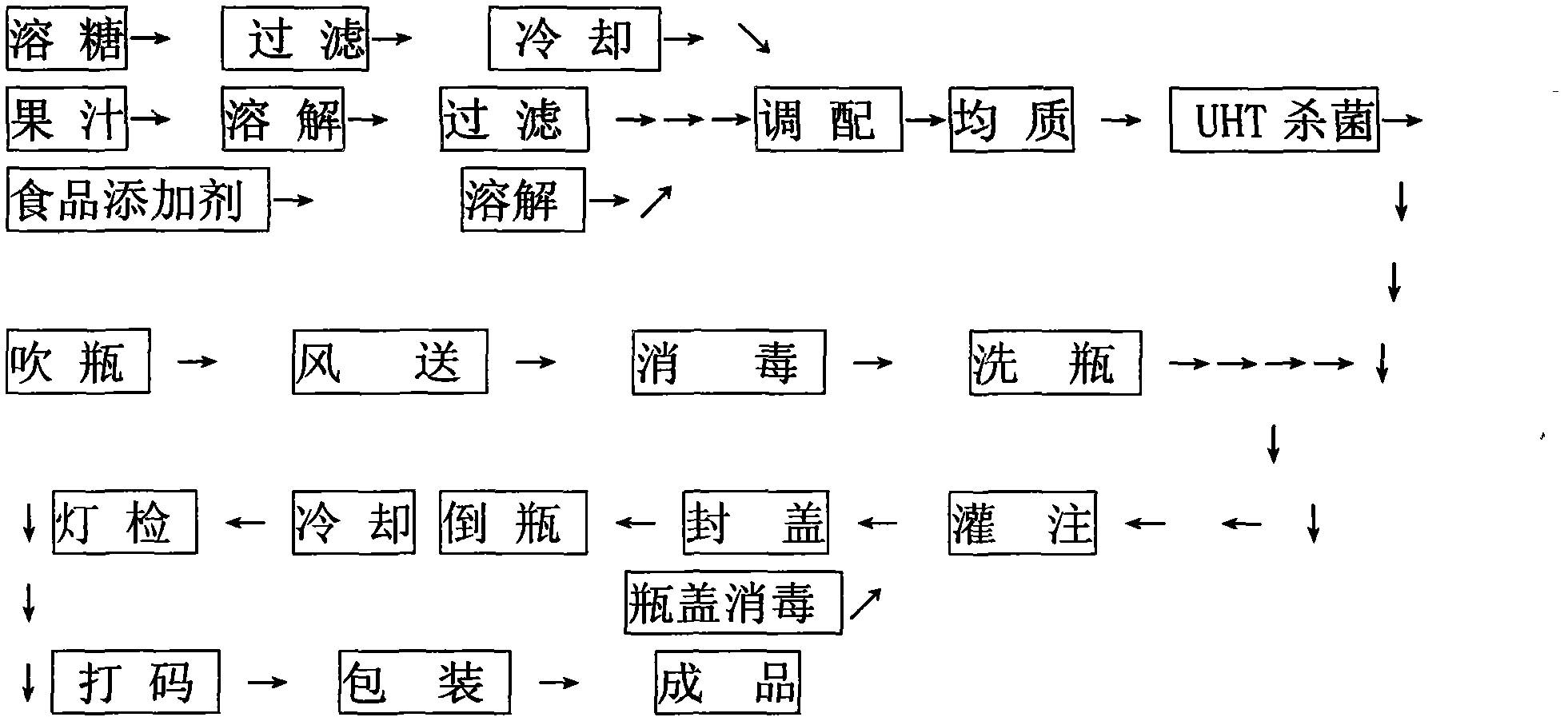

Image

Examples

Embodiment 1

[0023] Get the following mass ratio raw materials: 25% of blackberry juice, 0.15% of edible acid, 6% of edible sugar, 0.03% of pectin, 0.2% of honey and the rest of the water, and make it according to the following steps:

[0024] (1) Cool the fresh black raspberry fruit to 1°C, or heat up the black raspberry quick-frozen fruit to 1°C, use cold beating, filter with 300 mesh, and set aside;

[0025] (2) Edible acid, edible sugar, pectin, honey, water and other auxiliary materials are mixed, dissolved, filtered, and set aside;

[0026] (3) Mix the raw materials obtained in steps (1) and (2), constant volume, stirring, homogenization, degassing, high temperature instantaneous sterilization, temperature 118 ° C, time 5 seconds, volatile aroma substances are recycled into the high temperature instantaneous sterilization Condenser, finally mix volatile aroma substances and raw material liquid;

[0027] (4) Hot filling at 85°C, capping, cooling down to 35°C by spray cooling system c...

Embodiment 2

[0029] Get the following mass ratio raw materials: 30% of blackberry juice, 0.17% of edible acid, 7% of edible sugar, 0.03% of pectin, 0.3% of honey and the rest of the water, and make it according to the following steps:

[0030] (1) Cool down the fresh black raspberry fruit to 3°C, or heat up the black raspberry quick-frozen fruit to 3°C, use cold beating, filter with 300 mesh, and set aside;

[0031] (2) Edible acid, edible sugar, pectin, honey, water and other auxiliary materials are mixed, dissolved, filtered, and set aside;

[0032] (3) Mix the raw materials obtained in steps (1) and (2), constant volume, stirring, homogenization, degassing, high temperature instantaneous sterilization, temperature 118 ° C, time 5 seconds, volatile aroma substances are recycled into the high temperature instantaneous sterilization Condenser, finally mix volatile aroma substances and raw material liquid;

[0033] (4) Hot filling at 88°C, capping, cooling down to 38°C by spray cooling sys...

Embodiment 3

[0035] Get the following mass ratio raw materials: 40% of blackberry juice, 0.18% of edible acid, 8% of edible sugar, 0.04% of pectin, 0.3% of honey and the rest of the water, prepared according to the following steps:

[0036] (1) Cool down the fresh black raspberry fruit to 5°C, or heat up the black raspberry quick-frozen fruit to 5°C, use cold beating, filter with 300 mesh, and set aside;

[0037] (2) Edible acid, edible sugar, pectin, honey, water and other auxiliary materials are mixed, dissolved, filtered, and set aside;

[0038] (3) Mix the raw materials obtained in steps (1) and (2), constant volume, stirring, homogenization, degassing, high temperature instantaneous sterilization, temperature 118 ° C, time 5 seconds, volatile aroma substances are recycled into the high temperature instantaneous sterilization Condenser, finally mix volatile aroma substances and raw material liquid;

[0039] (4) Hot filling at 90°C, capping, cooling down to 40°C by spray cooling system...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com