Ice cream processed by PMF (palm-oil middle fractionation)-base composite grease and production method

A technology for ice cream and oil, applied in the application, frozen dessert, food science and other directions, can solve the problems of increasing demand and lack of taste, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The ice cream that utilizes the PMF base compound fat of the present invention to make, it is prepared from following raw material:

[0028] Get 6 parts of compound fats and oils prepared according to the ratio of 90:5:5 by palm oil intermediate fraction PMF, milk fat AMF and palm stearin ST; 8 parts of skimmed milk powder; 13 parts of sucrose; 0.25 part of sucrose ester; 0.25 parts of monoglyceride; 0.2 parts of guar gum; 72.3 parts of water; appropriate amount of spices and flavors;

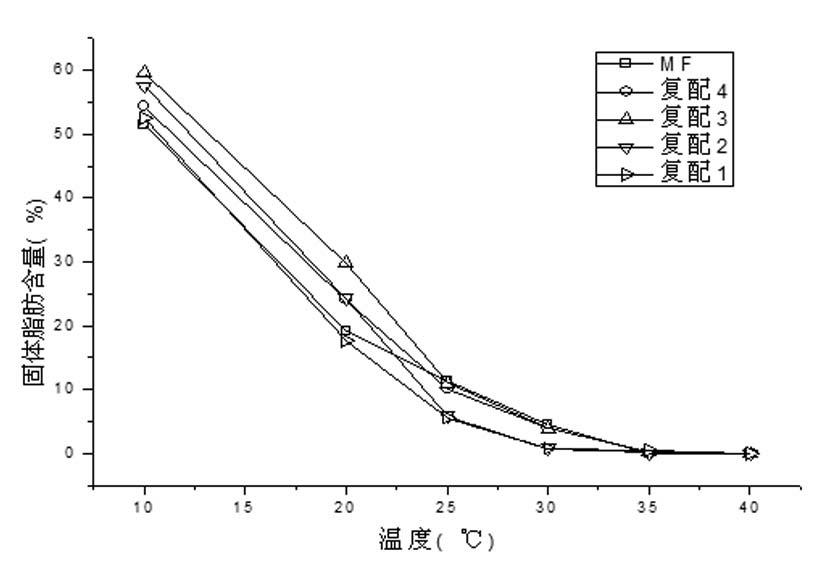

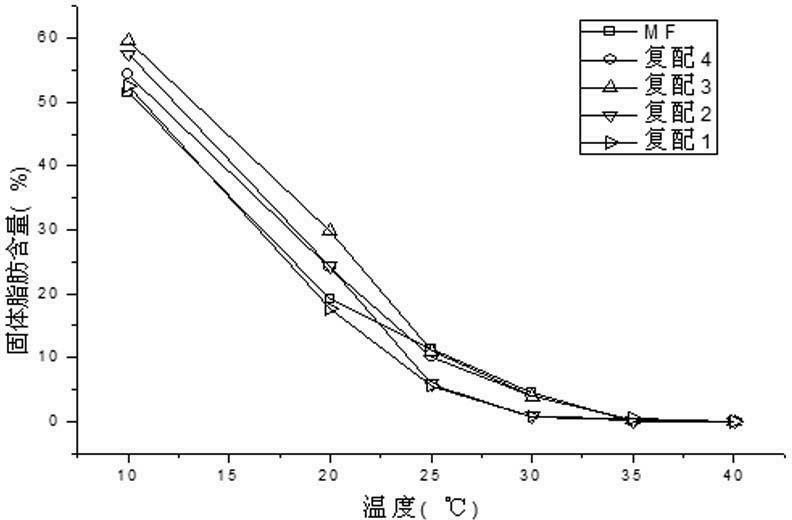

[0029] The melting point of the palm oil intermediate fraction PMF used is 26.4°C; the iodine value is 47.9 gI / 100g; the fatty acid composition (%) is: C14:0=0.92, C16:0=47.53, C18:0=5.09, C18 :1=37.91, C18:2=8.56; solid fat content (%): 5℃ 76.7, 10℃ 70.2, 20℃ 35.0, 25℃ 10.3, 30℃ 2.5;

[0030] The production method of ice cream of the present invention comprises the steps:

[0031] first step, mixing

[0032] Water phase solution: sucrose is completely dissolved in water and filtered,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com