Poultry egg windowing and sealing method

A poultry egg and window opening technology, which is applied in the field of poultry egg window opening and sealing, can solve problems such as difficult unification of standards, hatching failure, and low success rate of operation, and achieve the effects of guaranteed operation time, easy control of the process, and high hatching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

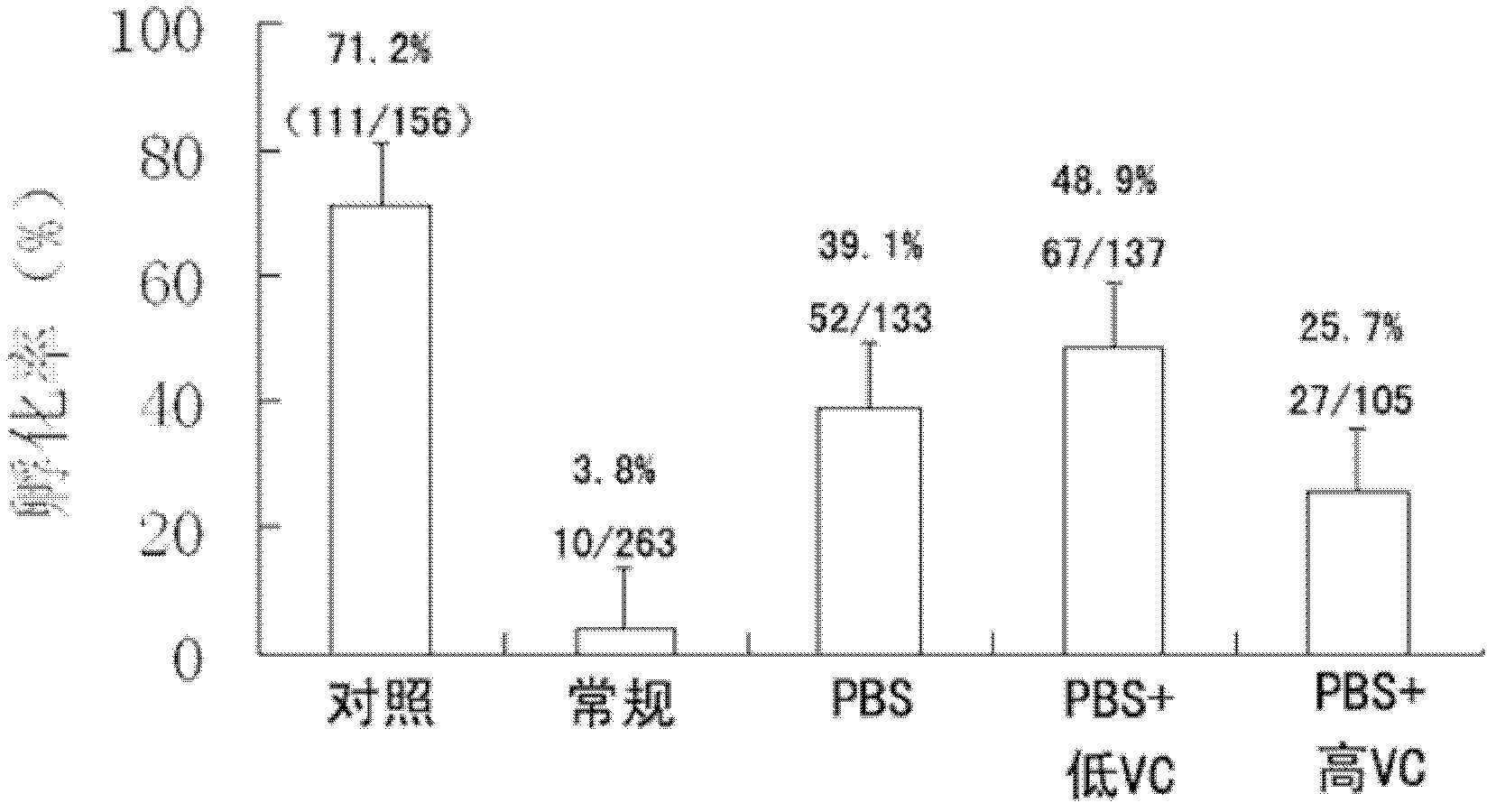

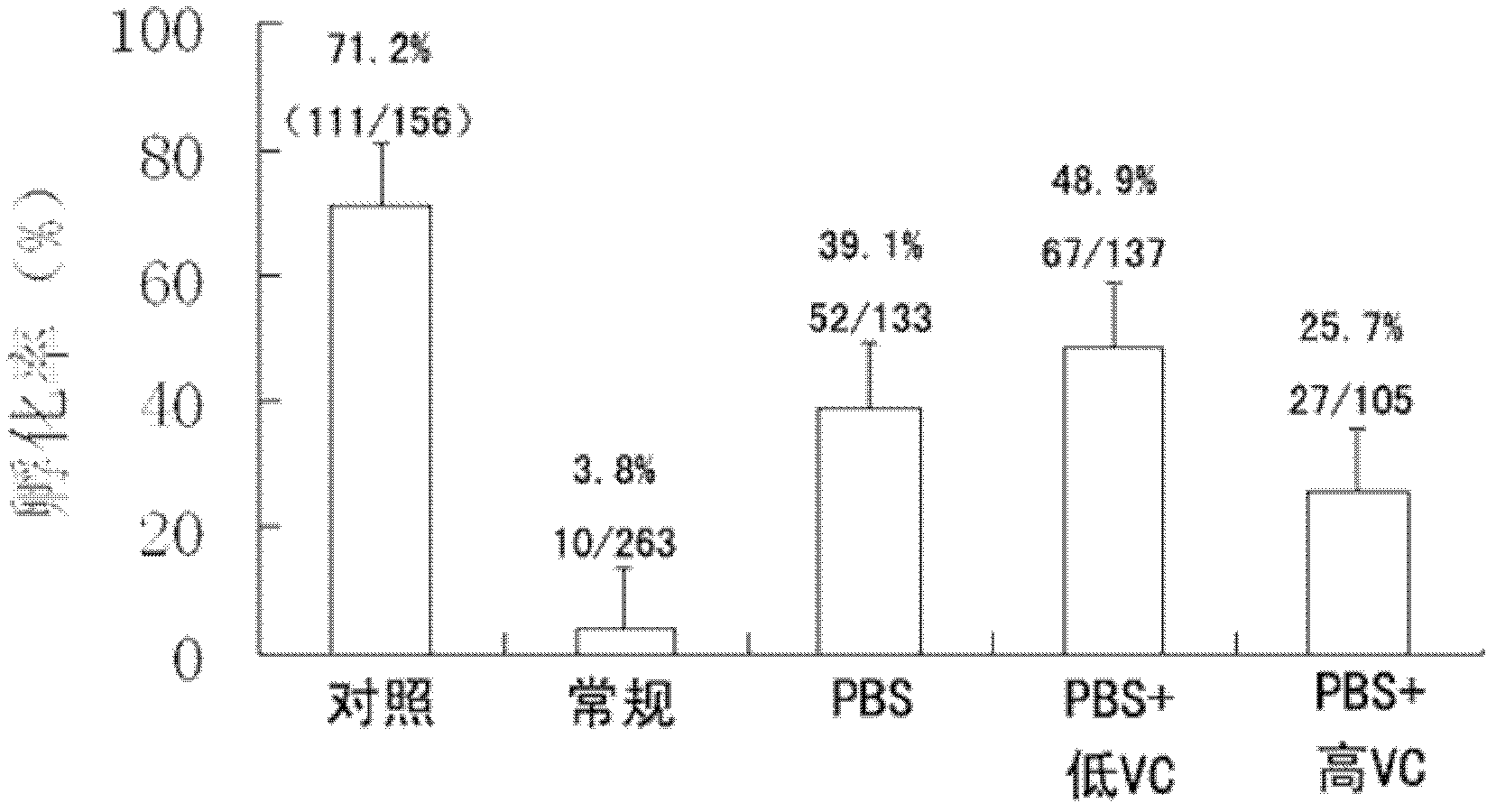

[0024] 1.1 Opening windows of poultry eggs: Fertilized eggs are taken from Taicang breeder farm of Wen's Group. The fresh fertilized eggs are sterilized by 75% alcohol and placed flat on the egg plate. After the highest point is marked with ordinary ink, the germinal disc is fixed overnight at room temperature. The next day, use a mini electric drill (Taiwan Baogong, model 1PK-500B-2) to polish a window of about 0.3-0.6 cm square at the mark on the side of the egg, while paying attention to maintaining the integrity of the eggshell membrane. Use a soft brush to clean the shell powder on the surface first, and then wipe it clean with 75% alcohol cotton balls. After drying, use a hot melt glue gun (Joel Thunder, model XL-E20K, ordinary EVA hot melt adhesive) to push the glue to make the hot melt The glue forms a concentric closed circle with the center of the window as the center and an inner diameter of about 1 cm. The hot-melt glue is solidified, and the concentric closed cir...

Embodiment 2

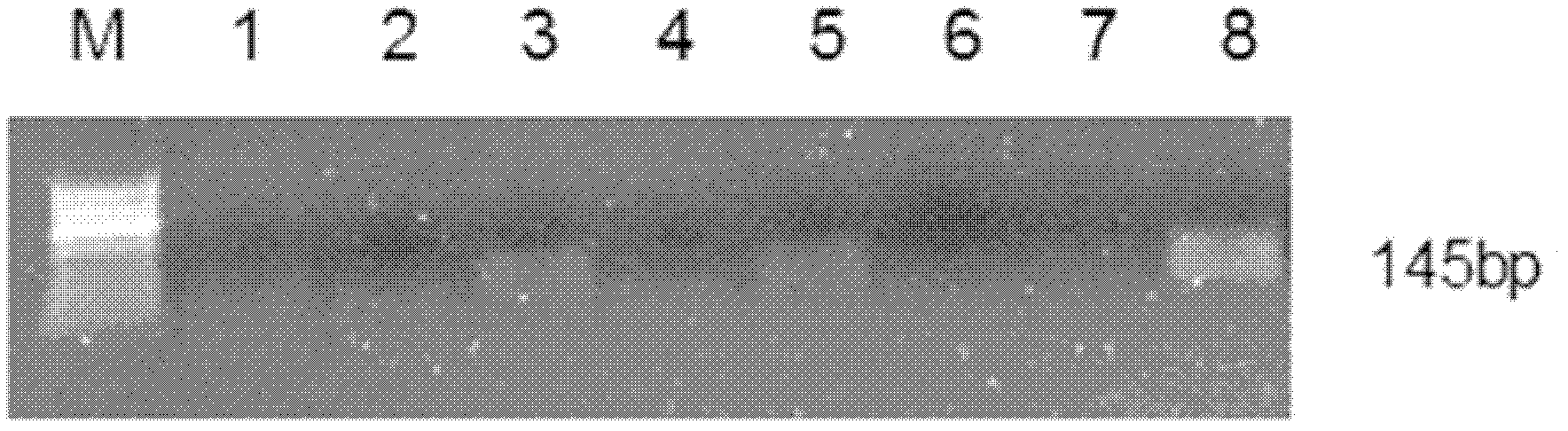

[0038] The fertilized eggs were taken from the Taicang breeder farm of Wen's Group. The fresh fertilized eggs are sterilized by 75% alcohol and placed flat on the egg plate. After the highest point is marked with ordinary ink, the germinal disc is fixed overnight at room temperature. The next day, use a mini electric drill (Taiwan Baogong, model 1PK-500B-2) to polish a window of about 0.3-0.6 cm square at the mark on the side of the egg, while paying attention to maintaining the integrity of the eggshell membrane. Use a soft brush to clean the shell powder on the surface, and then wipe it with 75% alcohol cotton balls. After drying, use gelatin to form a concentric closed circle with the center of the window as the center and an inner diameter of about 1 cm on the eggshell. After solidification, drop double-antibody (1‰w / v ampicillin and 1‰w / v streptomycin, the same below) and 2μg / ml PBS (pH7.2, 0.02M) in the gelatin ring to full , carefully cut the eggshell membrane along th...

Embodiment 3

[0040] The method is the same as in Example 2, only the gelatin is replaced by hot melt glue, the Vc concentration is changed to 20 μg / ml, the hatching rate reaches 45.2%, and the transgene detection efficiency is 48% in the effectively extracted samples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com