Method and device for power generation by utilizing low-temperature waste heat

A liquid inlet and electrode liquid technology, applied in circuits, fuel cells, electrical components, etc., can solve problems such as large water consumption, limited application areas, and increased power generation costs, achieving low water consumption, wide application areas, and power generation. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1. Method and device for generating electricity using low-temperature waste heat

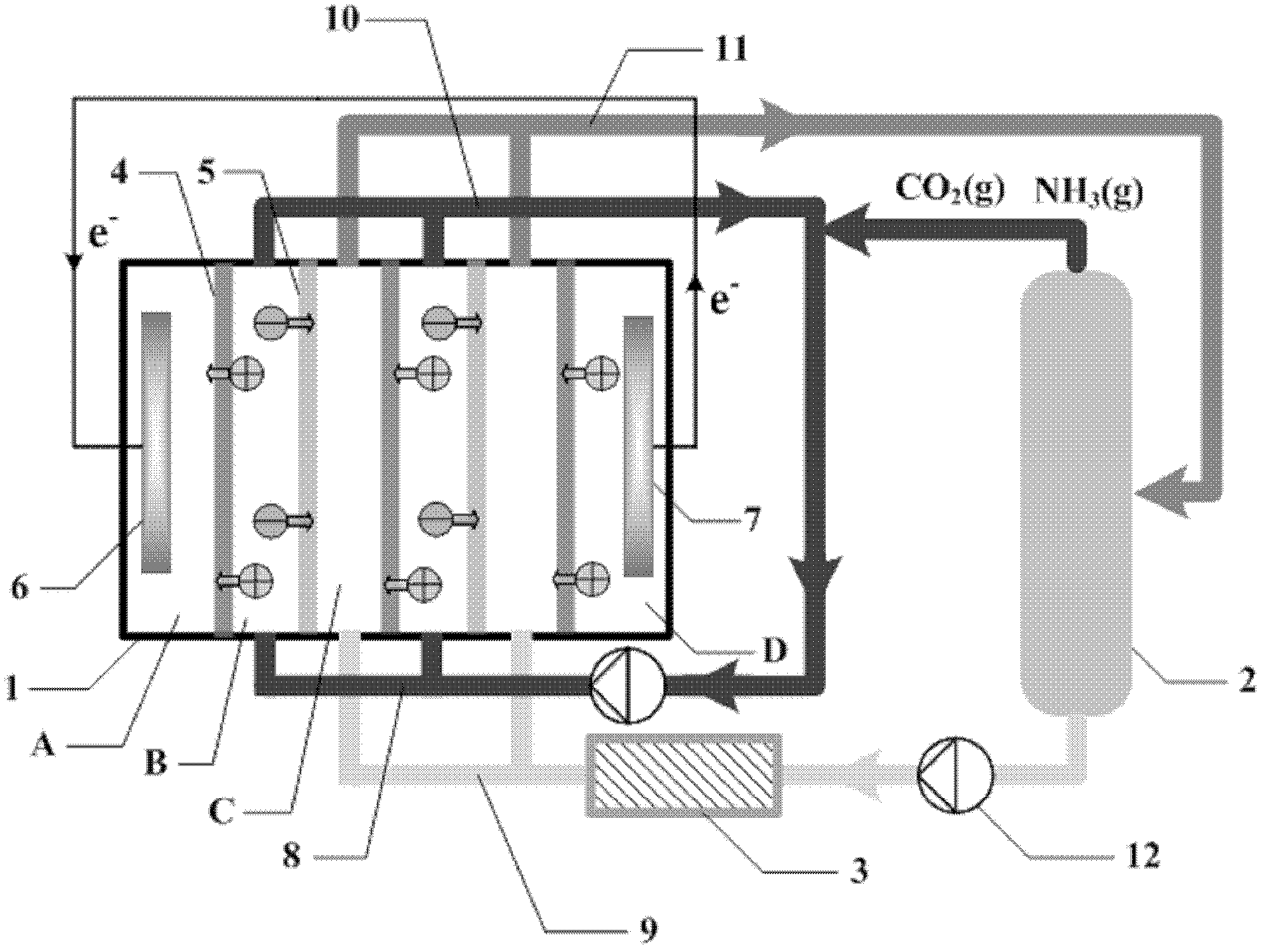

[0028] figure 1 It is a schematic diagram of the principle and device structure of the process of utilizing low-temperature waste heat for power generation in the present invention. The device is mainly composed of RED module 1 , distillation column 2 and heat exchanger 3 . Among them, the RED module 1 is mainly composed of a cathode 6, an anode 7, a cation exchange membrane 4 and an anion exchange membrane 5, and the module is provided with a cathode chamber A, a concentrated water chamber B, a fresh water chamber C and an anode chamber D. Both the cathode 6 and the anode 7 are titanium plates coated with ruthenium and iridium. The concentrated ammonium bicarbonate solution 8 and the dilute ammonium bicarbonate solution 9 flow through the concentrated water chamber B and the fresh water chamber C respectively, and the solutions are delivered by a peristaltic pump 12 .

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Burst strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com