Light emitting diode packaging structure and manufacturing method of light emitting diode packaging structure

A technology for light-emitting diodes and packaging structures, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of large substrate thickness, low yield, and complex packaging structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

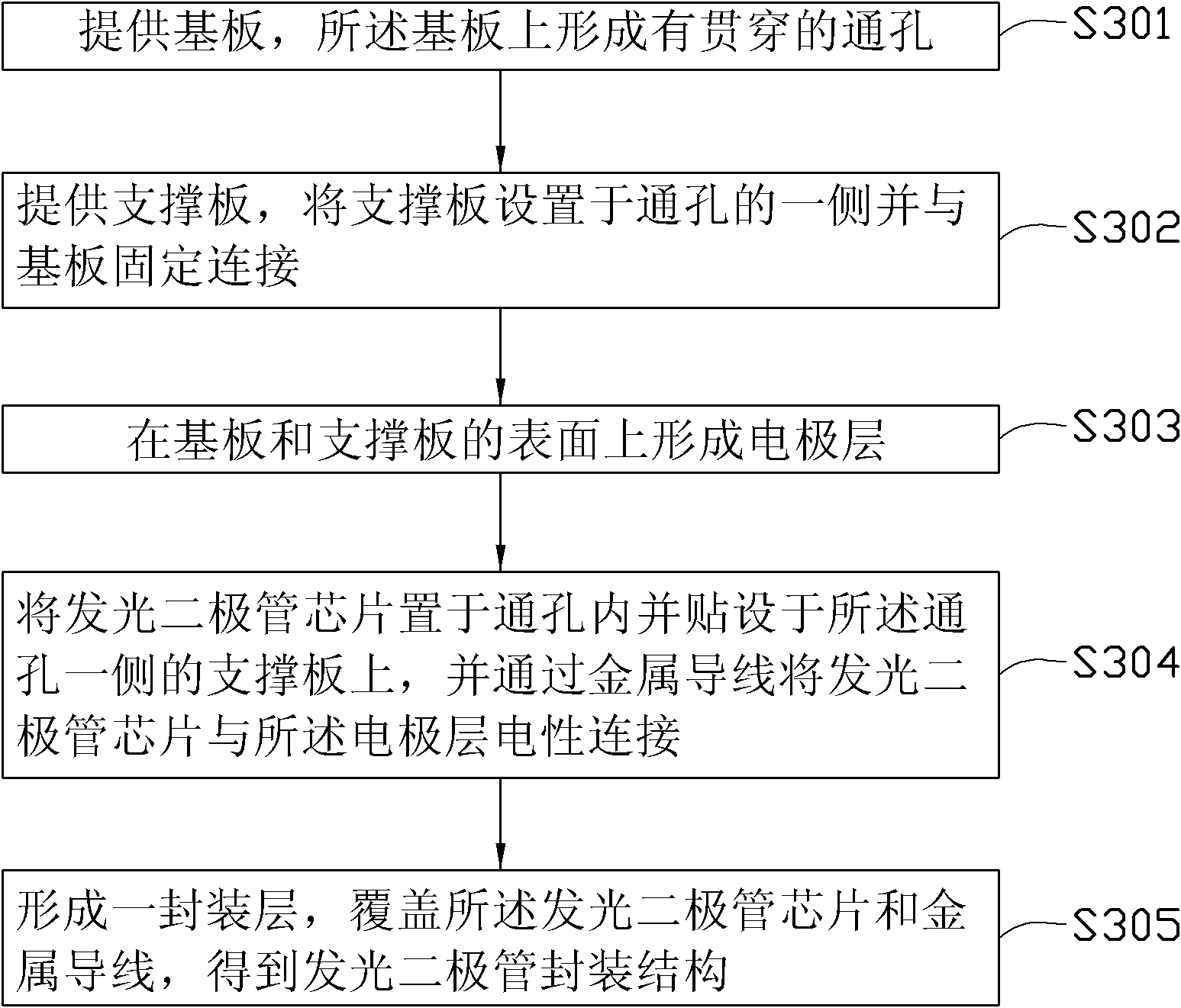

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings.

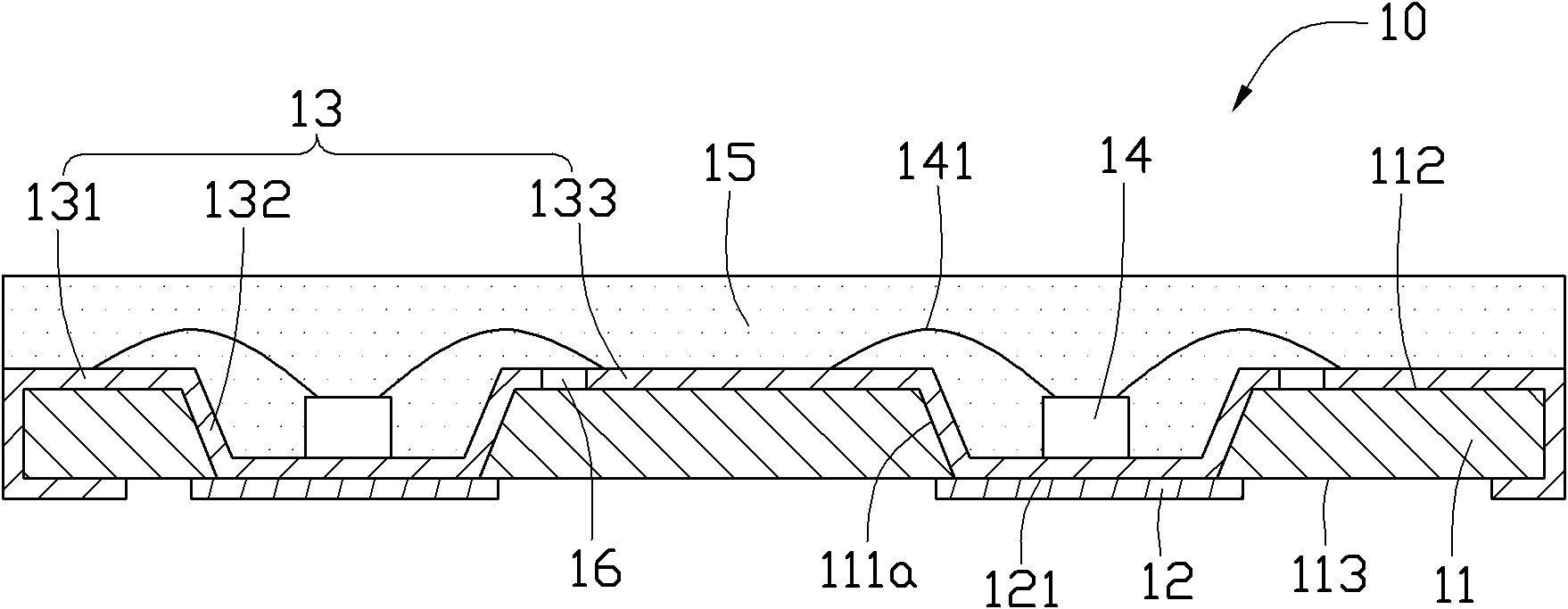

[0035] see figure 1 , The first embodiment of the present invention provides a LED packaging structure 10 , which includes a substrate 11 , several support plates 12 , an electrode layer 13 , several LED chips 14 and a packaging layer 15 .

[0036] see Figure 4 , the substrate 11 is in the shape of a plate, and a through hole 111 is formed on the substrate 11 , and the substrate includes a first surface 112 and a second surface 113 opposite to each other. The substrate 11 is used to support the LED packaging structure 10 . The through hole 111 is bounded by an inclined side surface 111 a and penetrates downwardly from the first surface 112 of the substrate 11 to the second surface 113 of the substrate 11 . The material of the substrate 11 is bismaleimide triazine resin (Bismaleimide Triazine resin, BT resin) or epoxy glass cloth. The thickness of the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com