Hardware equipment automation testing system and testing method thereof

A technology for automated testing and hardware equipment, applied in the detection of faulty computer hardware, etc., can solve problems such as inability to support GUI automation and inflexible parameter transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

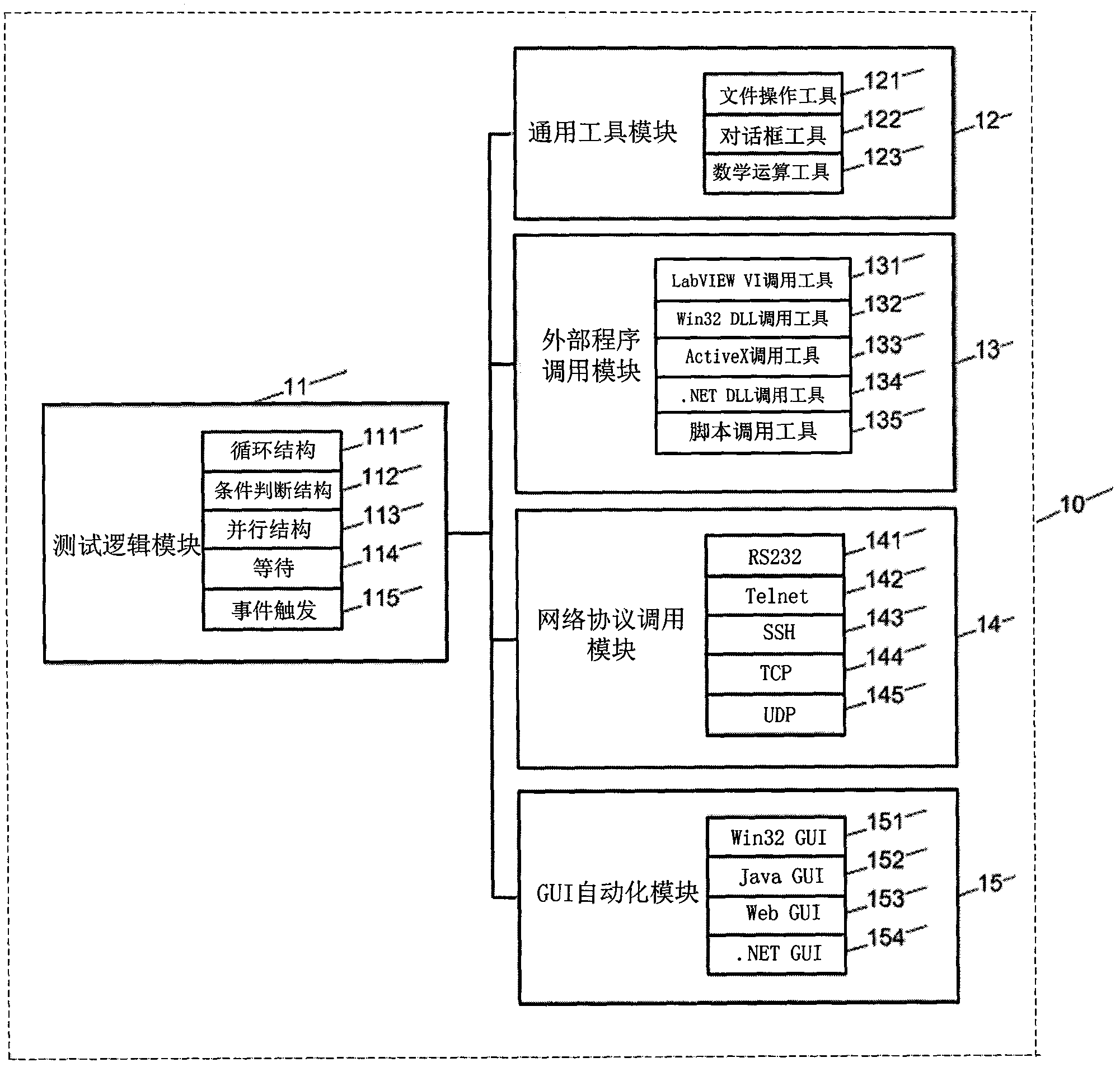

[0081] see figure 1 , the present invention discloses a system 10 capable of creating automatic test cases for various complex hardware devices without programming. Hardware device testing may involve various tools and methods, and the system includes a test logic module 11 , a general tool module 12 , an external program calling module 13 , a network protocol module 14 and a GUI automation module 15 .

[0082] 【Test logic module】

[0083] The test logic module 11 includes tools for implementing various test logics, such as loop structure 111 , condition judgment structure 112 , parallel structure 113 , waiting 114 , event trigger 115 and so on. These tools are used to implement various test logics and combine tools in other modules into a complete test process.

[0084] The loop structure 111 is used to implement steps that require loops in the test process. It can be divided into two types: the loop with a certain number of loops - just set the number of loops; it is nece...

Embodiment 2

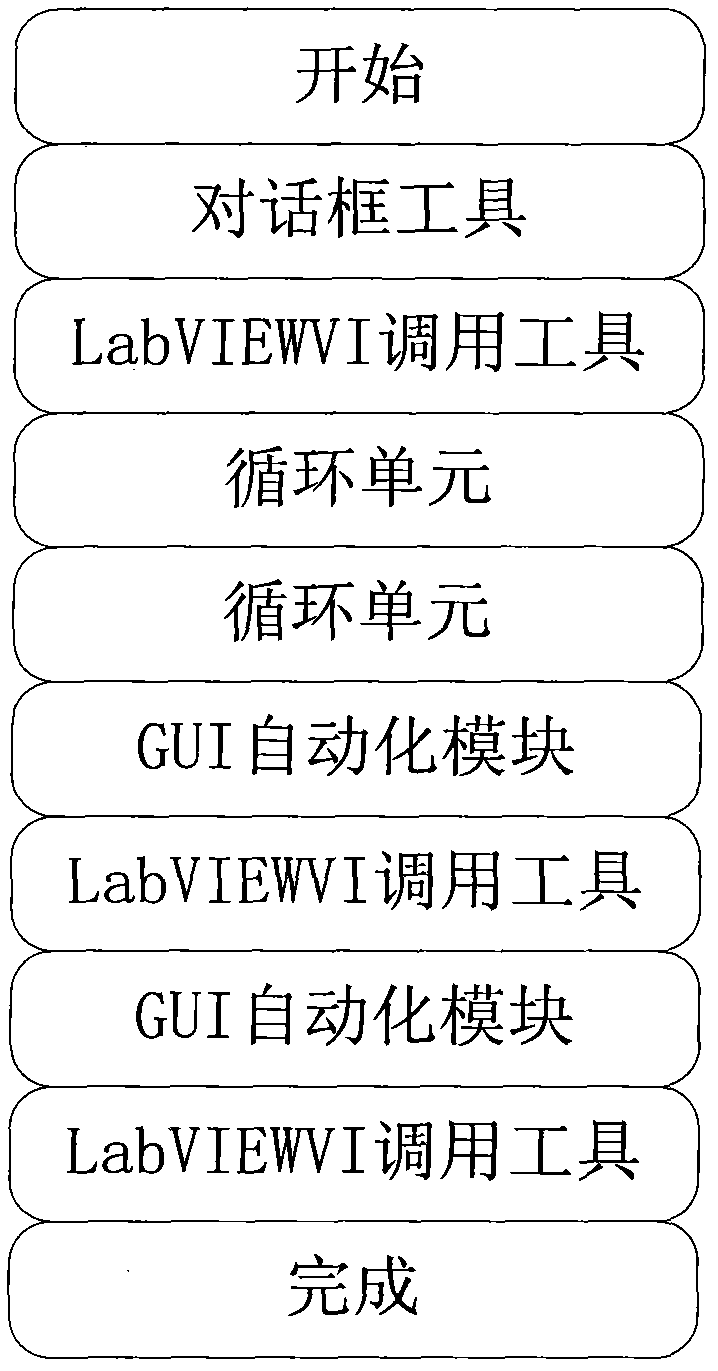

[0116] This embodiment introduces the present invention by taking the TD-LTE (fourth generation mobile communication) base station vector magnitude error test as an example.

[0117] The testing process is as follows:

[0118] Use case description: Verify that the EVM of the eNodeB's transmitted signal complies with the regulations

[0119] Testing process:

[0120] 1) Configure the carrier frequency point, the center frequency is 2350MHz;

[0121] 2) Start eNodeB to work in E-TM3.1 mode and transmit with maximum power;

[0122] 3) Use the LTE spectrum analyzer to test the PDSCH EVM whose modulation mode is 64QAM;

[0123] 4) Change the downlink signal mode to E_TM3.2, and test the PDSCH EVM whose modulation mode is 16QAM;

[0124] 5) Change the downlink signal mode to E_TM3.3, and test the PDSCH EVM whose modulation mode is QPSK;

[0125] 6) Change the downlink signal mode to E_TM2, and test the PDSCH EVM whose modulation mode is 64QAM;

[0126] 7) Configure the carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com