Galloping test machine power loading device for transmission tower tension change research

A technology of transmission tower and loading device, which is applied in measurement device, vibration test, machine/structural component test, etc., can solve the problems of main material fracture, transmission tower damage, economic loss, etc., and achieve the effect of reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

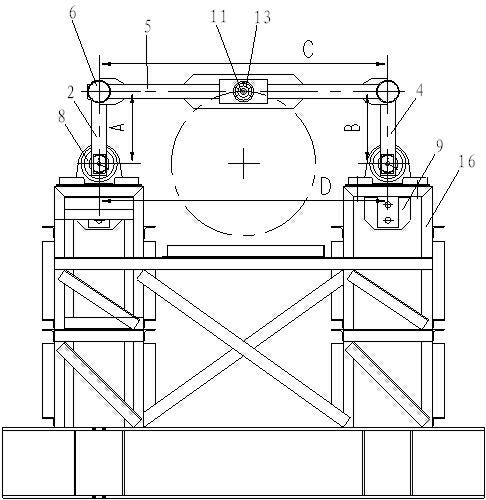

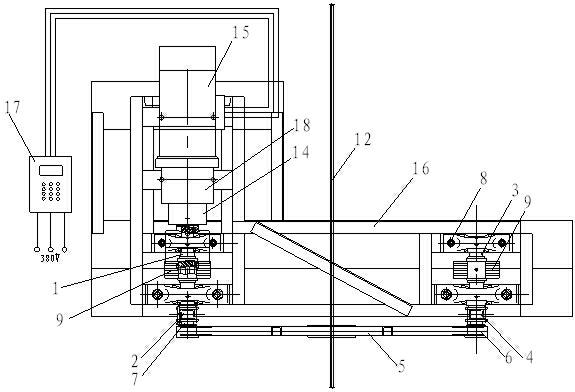

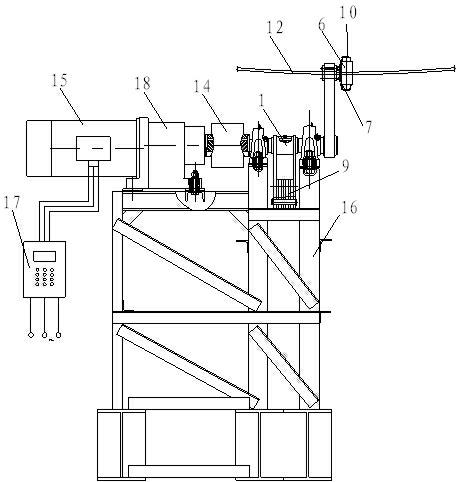

[0025] Such as figure 1 , 2 , 3, the present invention includes a frame 16, a drive mechanism installed on the frame 16 and a parallel four-bar mechanism. The driving mechanism drives the parallel four-bar mechanism to rotate back and forth. The drive mechanism includes a frequency conversion motor 15; the parallel four-bar mechanism includes a driving arm 2, a driven arm 4 and a connecting rod 5, and the driving arm 2, driven arm 4, connecting rod 5 and frame 16 together form a parallel four-bar mechanism.

[0026] The left and right sides of the frame 16 are respectively equipped with a driving shaft 1 and a driven shaft 3, and the driving shaft 1 and the driven shaft 3 are all fixed on the frame 16 through the support bearing 8 and bolts. The other end of the drive shaft 1 is connected to the variable frequency motor 15 through a coupling 14, and the variable frequency motor 15 is fixed on the frame 16 by a screw, and the speed control of the variable frequency motor 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com