Stator component of charging pump for nuclear power station

A technology for nuclear power plants and components, which is applied to the components, pump elements, pumps, etc. of pumping devices for elastic fluids. It can solve the inconvenience of sand cleaning and grinding in the inner flow channel, certain displacement in the axial direction, and high casting difficulty. problems, to achieve the effect of reducing the difficulty of casting process, improving efficiency and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

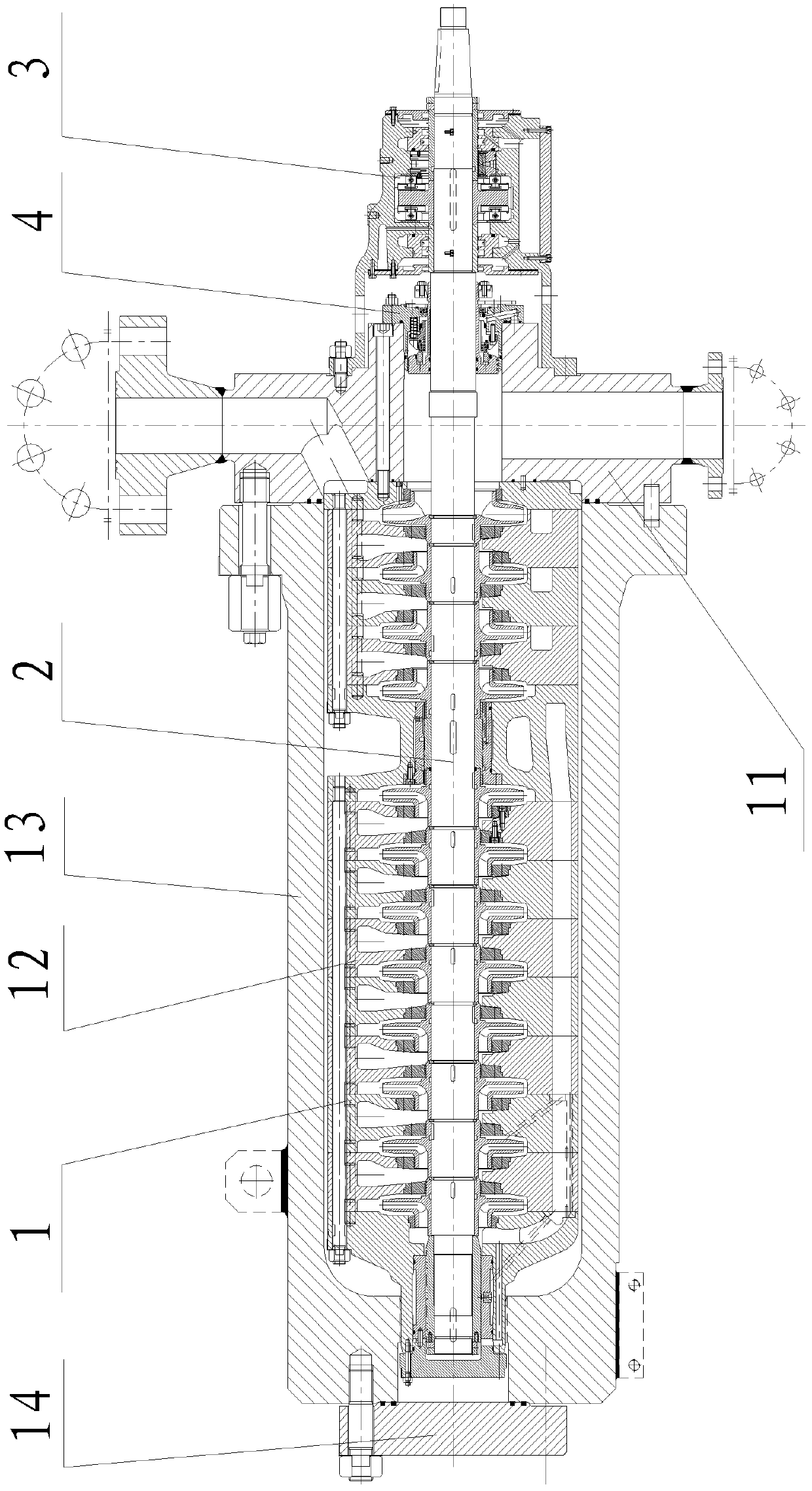

[0036] see figure 1 , The upper charging pump used in nuclear power plants includes a stator part 1, a rotor part 2, a bearing part 3 and a mechanical seal 4.

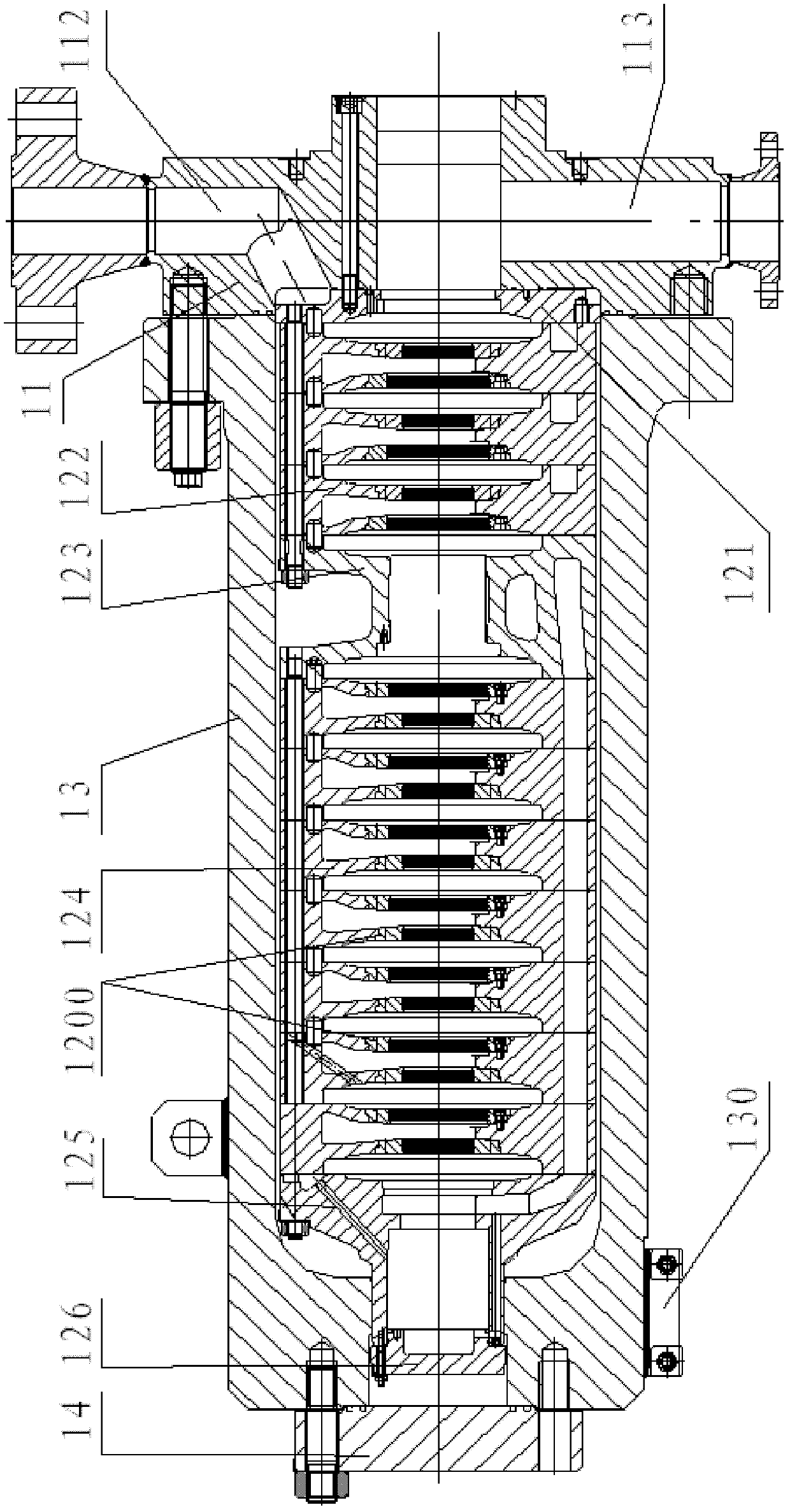

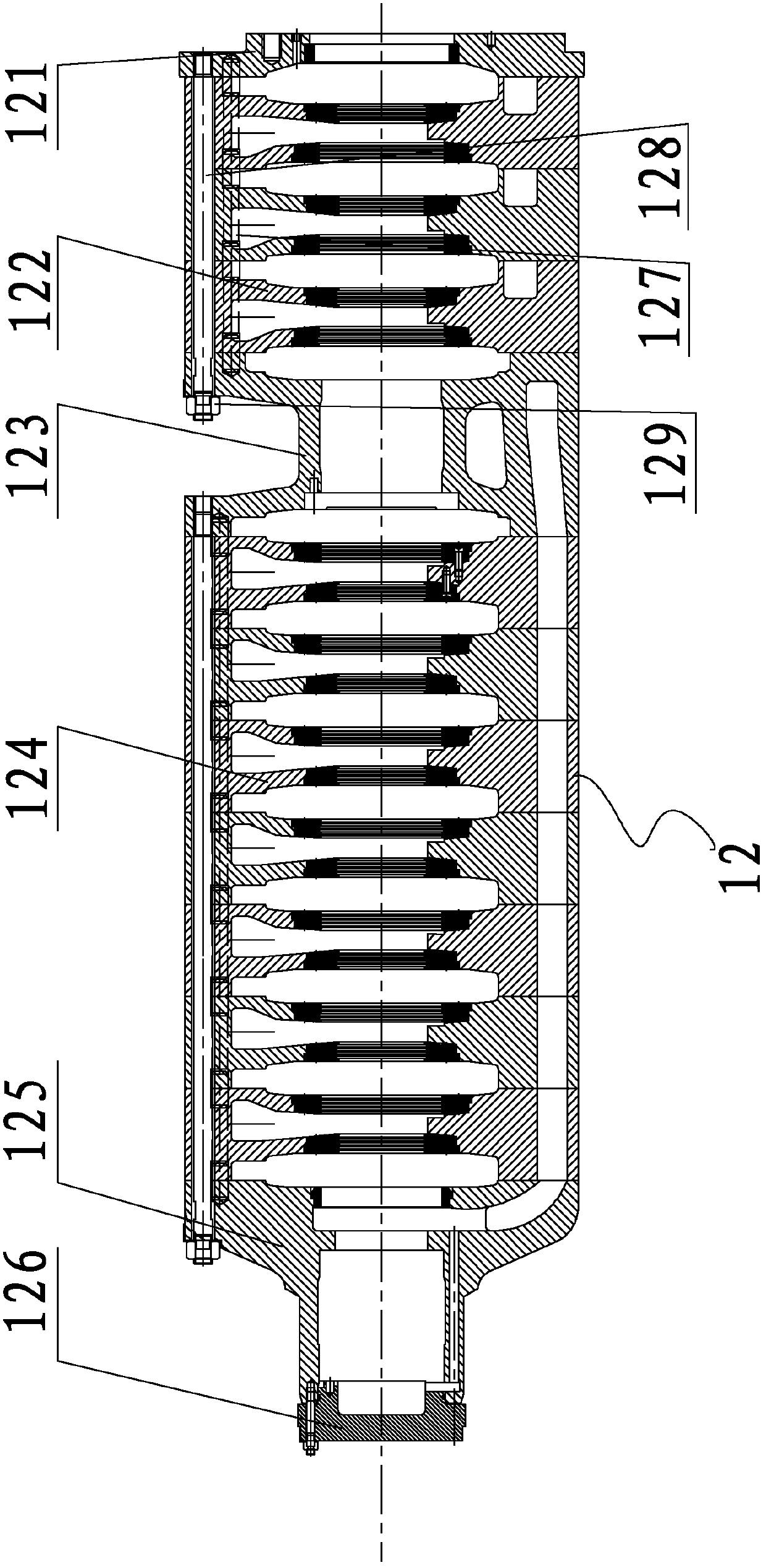

[0037] see again figure 2 , The stator part of the upper charging pump used in the nuclear power plant of the present invention includes a pump head 11, a cylinder body and a tail plate 14 which are sequentially connected back and forth. Among them, the barrel includes an outer shell 12 and an inner shell 13, and a barrel slideway block 130 is provided at the connecting position between the barrel and the pump base to ensure high repositionability of the upper charging pump when disassembled and installed; The components can withstand the axial extension during thermal expansion, without affecting the center of the pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com