Novel quick digging and anchoring integrated machine for rectangular coal roadway

An all-in-one machine and rectangular technology, which is applied in the direction of cutting machinery, slitting machinery, bolt installation, etc., can solve the problems of low bolter operation efficiency, increased excavation cost, and affecting mining efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

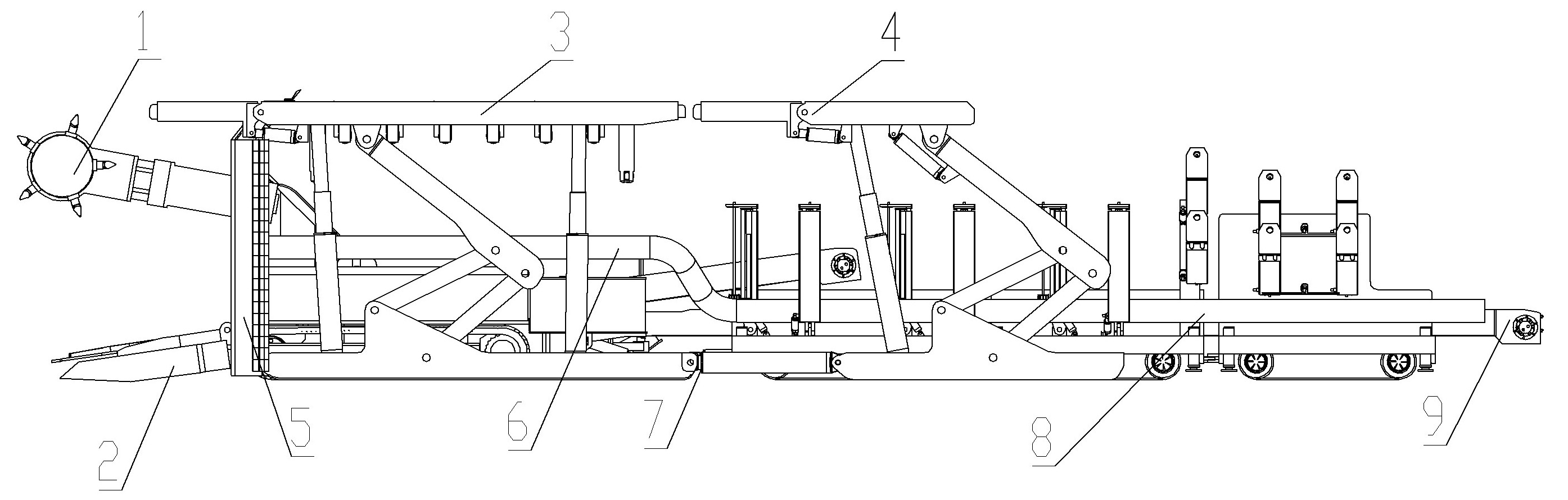

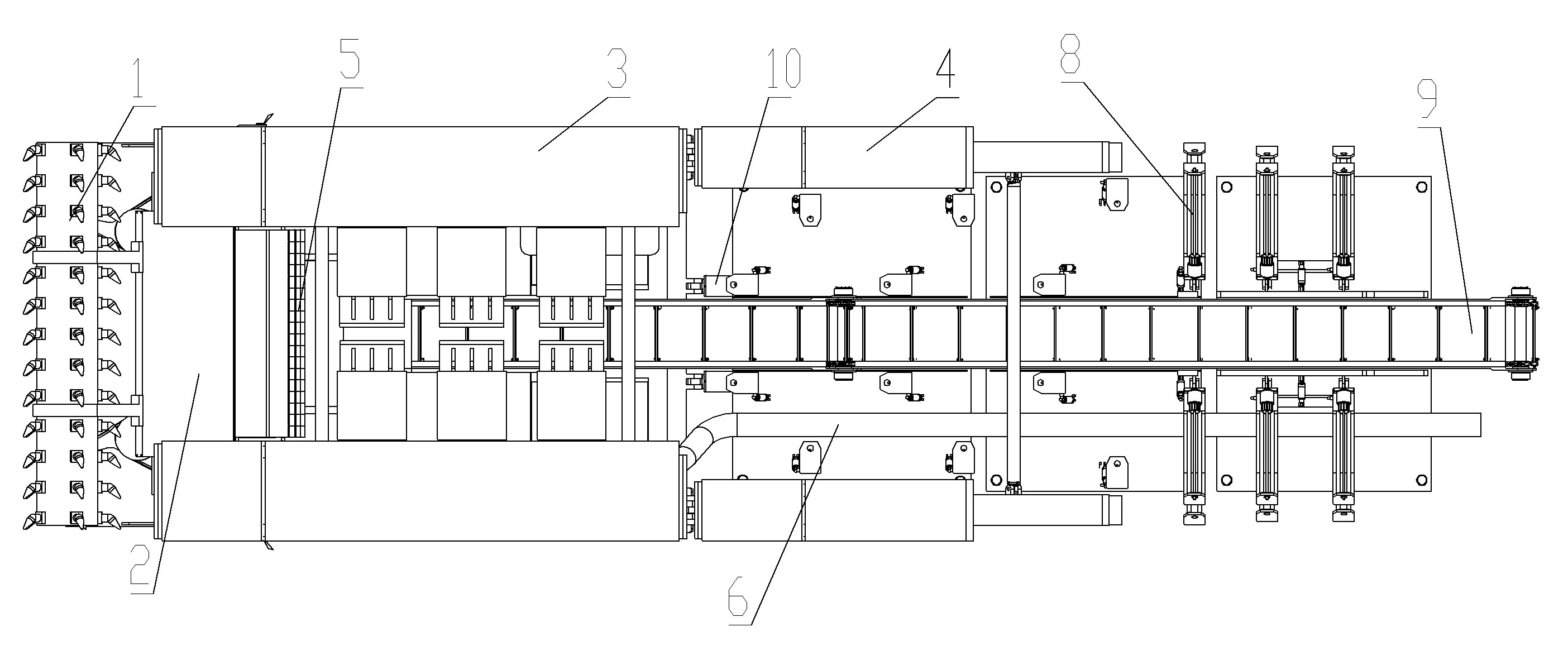

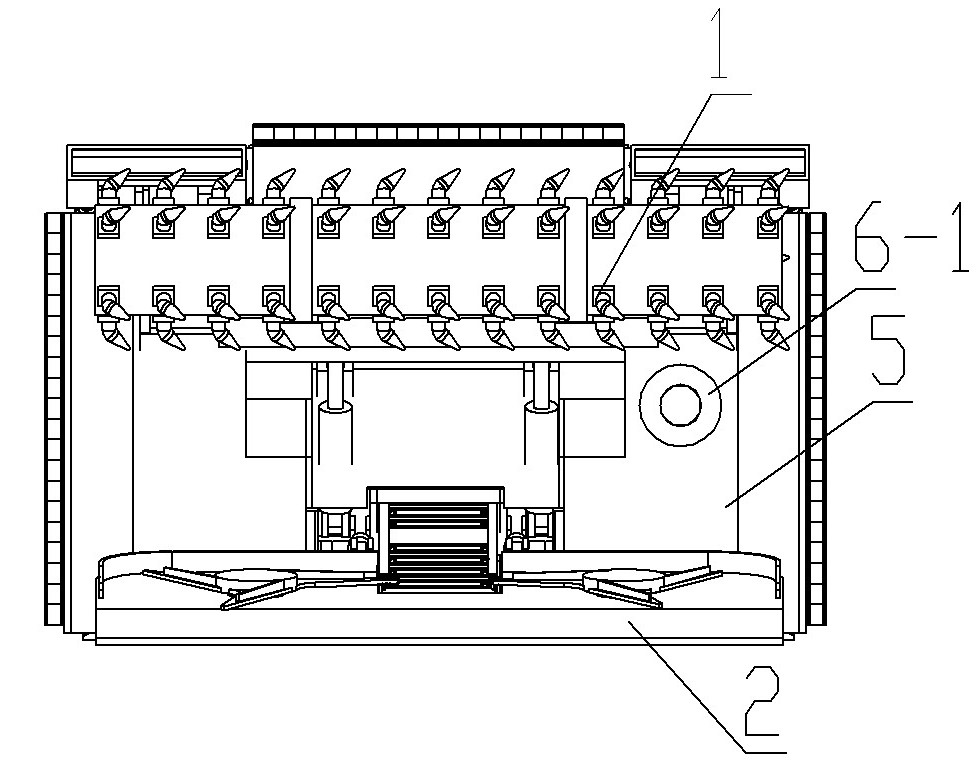

[0030] Example: see Figure 1-Figure 14 In the figure, a new type of fast and bolt-digging all-in-one machine for rectangular coal roadway, including a roadheader, a temporary support system, an anchor system, a conveying system, and a dust removal system. The roadheader is located at the front, and the anchorage system is installed at the rear of the roadheader. The left and right sides and the top of the roadheader rear and the front of the anchoring system are temporary support systems, and the conveying system is a scraper conveyor installed inside the roadheader and the anchorage system; the nose of the roadheader and A sealing device is provided between the front parts of the support system, the sealing device includes the main body plate, the upper movable sealing plate hinged on the upper part of the main body plate, the left and right movable sealing plates hinged on both sides of the main body plate, and the main body plate and the upper movable sealing plate The bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com