Three-in-one spunlaced composite non-woven fabric

A non-woven fabric, three-in-one technology, used in non-woven fabrics, textiles and papermaking, etc., can solve the problems of poor strength, no moisture absorption, hydrophilicity and degradability, lack of strength, etc., to achieve a simple overall structure, Good hygroscopic effect, excellent water-absorbing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

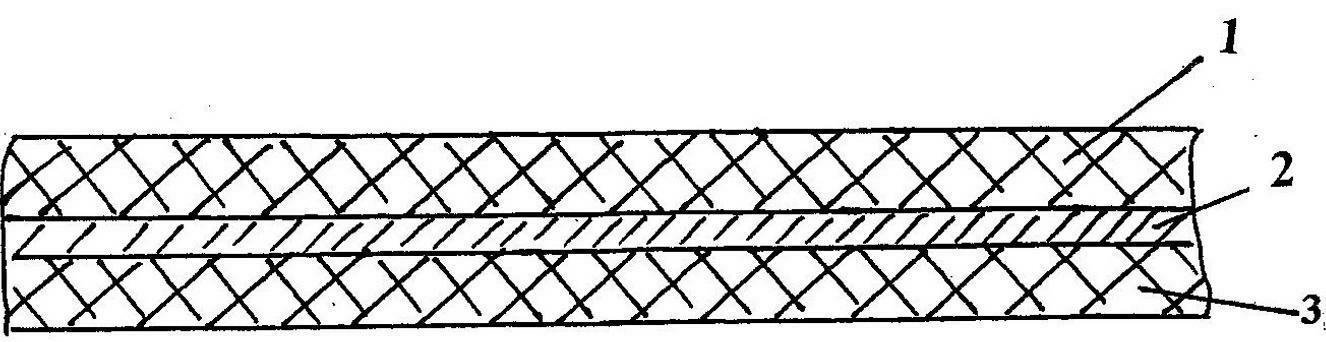

[0017] See figure 1 , the three-in-one spunlace composite nonwoven of the present invention is composed of a substrate layer 1, a hygroscopic layer 2 and a hydrophilic layer 3, and the substrate layer 1, the hygroscopic layer 2 and the hydrophilic Layer 3 is combined as a whole, more specifically, the fibers of substrate layer 1, fibers of moisture absorption layer 2 and fibers of hydrophilic layer 3 are entangled together by spunlace, wherein: moisture absorption layer 2 is located between the substrate layer 1 and the hydrophilic layer 3.

[0018] In this embodiment, the grammage of the substrate layer 1 is 40g / ㎡, and the material of the substrate layer 1 is polyester staple fiber with a fiber length of 38-65㎜; The material of layer 2 is wood pulp fiber with a fiber length of 2-5 mm, which is obtained from wooden pulp boards. Specifically, the pulp boards are pulverized by a hydraulic pulper and introduced into the storage tank, and then the storage tank is pumped into...

Embodiment 2

[0020] Only change the weight of substrate layer 1 to 100 g / ㎡, and use polypropylene staple fibers with a length of 38-65㎜ as the material; change the weight of moisture-absorbing layer 2 to 50 g / ㎡, and change the length of wood pulp fibers to 4-10㎜; the weight of the hydrophilic layer 3 is changed to 20 g / ㎡, the material is changed to degradable short-fiber polylactic acid spun-bonded non-woven fabric, and the length of the short-fiber polylactic acid is changed to 38-65㎜ to obtain 170 The three-in-one spunlace composite nonwoven fabric of g / ㎡, all the other are the same as the description to embodiment 1.

Embodiment 3

[0022] Only change the weight of substrate layer 1 to 20 g / ㎡, and use short milk fibers with a fiber length of 38-65㎜ as the material; change the weight of moisture-absorbing layer 2 to 30 g / ㎡, and change the length of wood pulp fibers to 3-6㎜; the weight of the hydrophilic layer 3 is changed to 20 g / ㎡, the material is polypropylene spun-bonded non-woven fabric, and the length of the polypropylene staple fiber is 38-65㎜, to obtain 70 g / ㎡ three-in-one water Prickly composite nonwoven fabric, all the other are with the description to embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com