Regular nitrogen doped graphene and preparation method thereof

A nitrogen-doped graphene and carbon-nitrogen source technology, applied in gaseous chemical plating, metal material coating process, coating, etc., to achieve low economic cost, simple preparation process, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The first step, the preparation of catalyst:

[0041] The substrate is ultrasonically cleaned with deionized water, detergent, ethanol, acetone, etc. and then dried, and then processed by chemical vapor deposition, physical vapor deposition, vacuum thermal evaporation, magnetron sputtering, plasma enhanced chemical vapor deposition or Deposition techniques such as printing deposit a layer of metal or metal compound (such as zinc sulfide, zinc oxide, gold, silver, copper, iron, cobalt, nickel, etc.) on the surface of the substrate as a catalyst; or gold, Silver, copper, iron, cobalt, nickel and other foils.

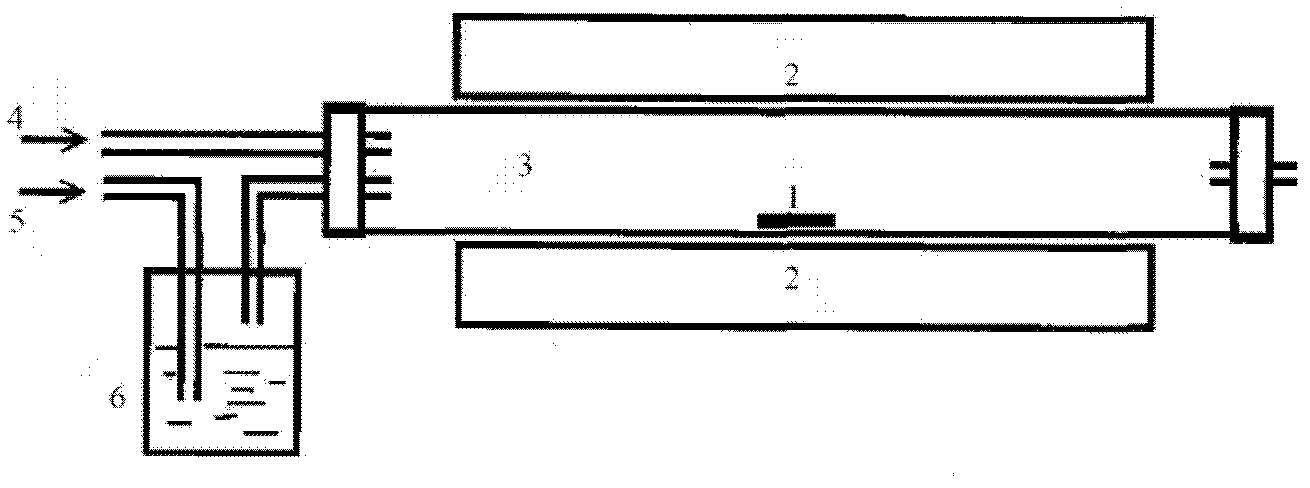

[0042] The second step: chemical vapor deposition equipment such as figure 1 As shown, the catalyst is placed in the middle of a clean quartz tube, the middle part of the electric furnace is facing the catalyst, and then the air in the quartz tube is removed by repeated vacuuming three times, or 10-3000 sccm non-oxidizing Gas (such as hydrogen, argon, nitrogen, et...

Embodiment 1

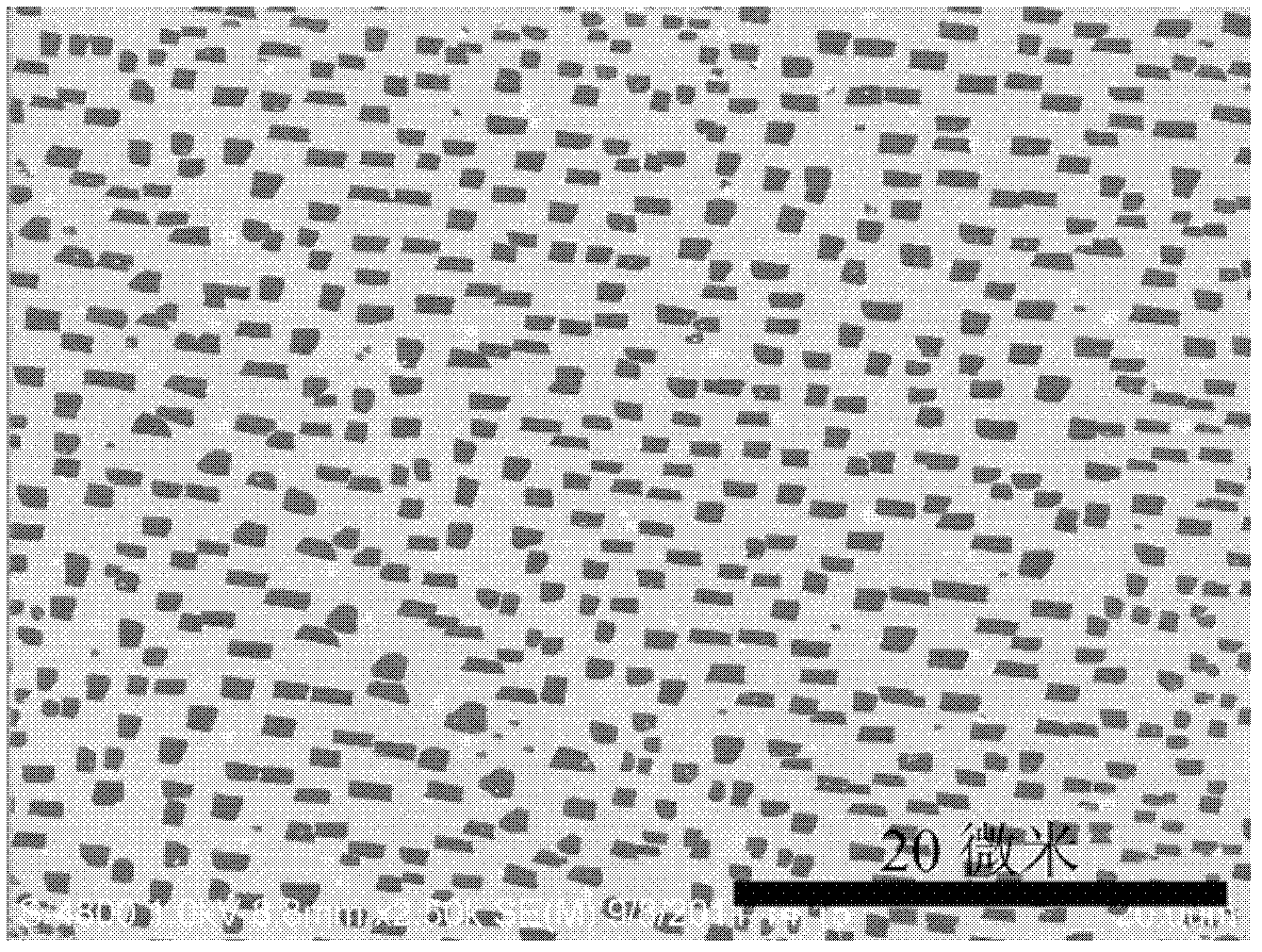

[0046] Example 1. Preparation of nitrogen-doped graphene with regular morphology on a copper-based substrate

[0047] Step 1: Clean the copper foil with deionized water, ethanol, and acetone ultrasonically, then dry it in an oven, and then put it into the quartz tube of the chemical vapor deposition system. Align the center of the high-temperature furnace with the copper foil. The vacuum completely removes the air in the furnace. Through 100sccm H 2 And 20sccm Ar mixed gas as carrier gas, start heating.

[0048] Step 2: When the temperature in the central area of the furnace reaches 300°C, pass the carrier gas through figure 1 6 in the carbon nitrogen source (the carbon nitrogen source is pyridine, and the flow rate of carrier gas is 100sccm H 2 and 20sccm Ar. ) into the reaction system, the reaction begins.

[0049] Step 3: After the reaction is carried out for 5 minutes, change the carrier gas path to not pass through the carbon and nitrogen source, and at the same ti...

Embodiment 2

[0051] Example 2, preparation of nitrogen-doped graphene with regular morphology

[0052] The preparation method is basically the same as in Example 1, except that when the temperature of the electric furnace reaches 200°C, pyridine is introduced as a carbon and nitrogen source, and the scanning electron micrograph of the product is as follows: Figure 6 As shown, the regular tetragonal structure can be seen from the figure, indicating that the product is regular nitrogen-doped graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com