Multi-luminous-region luminous Ag, Ga and N doping ZnO film and preparation method of multi-luminous-region luminous Ag, Ga and N doping ZnO film

A thin film and co-doping technology, applied in the field of ZnO thin film and its preparation, can solve the problems of less luminous area and weak luminous intensity, and achieve the effect of improving luminous intensity and increasing luminous intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

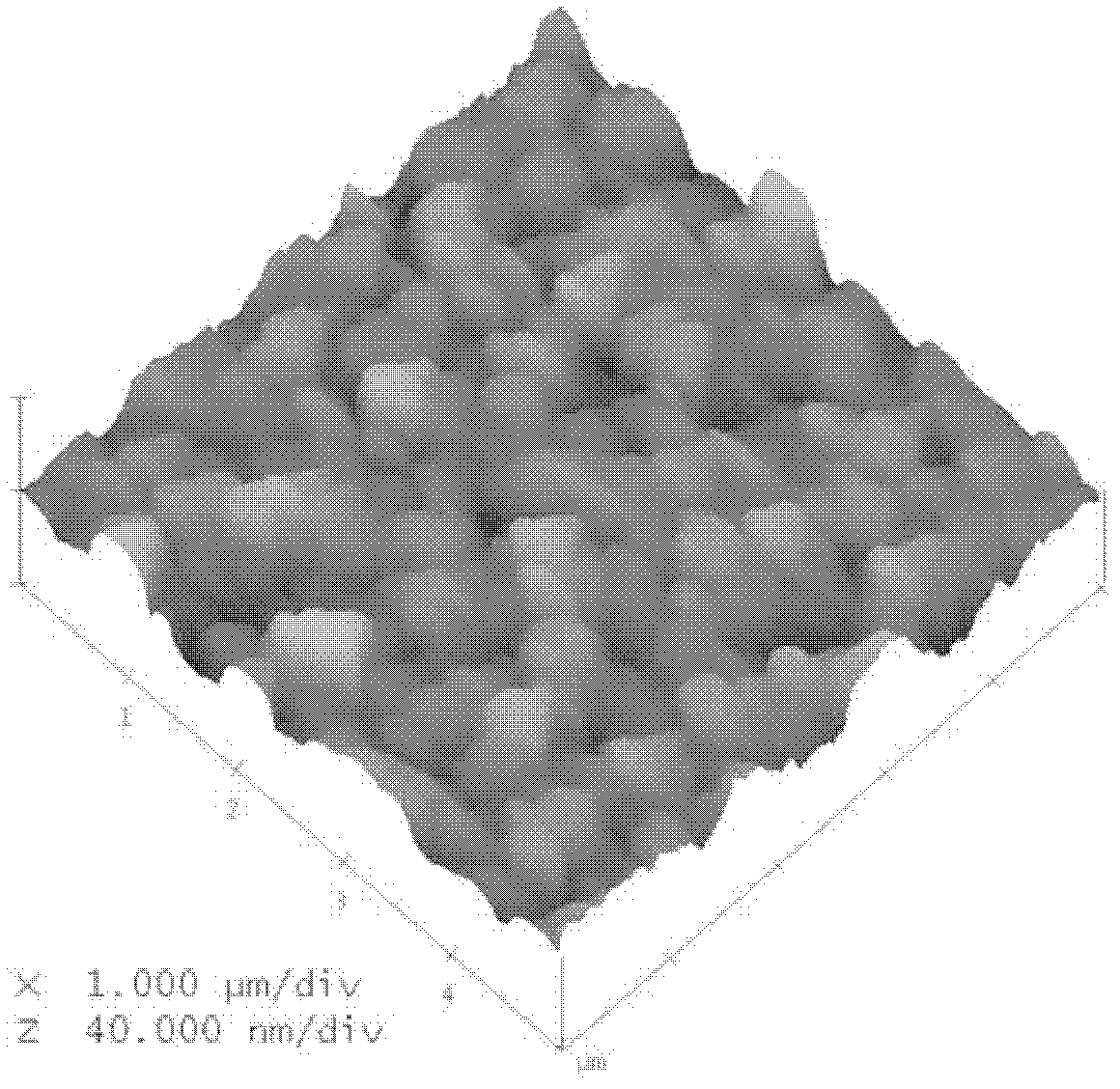

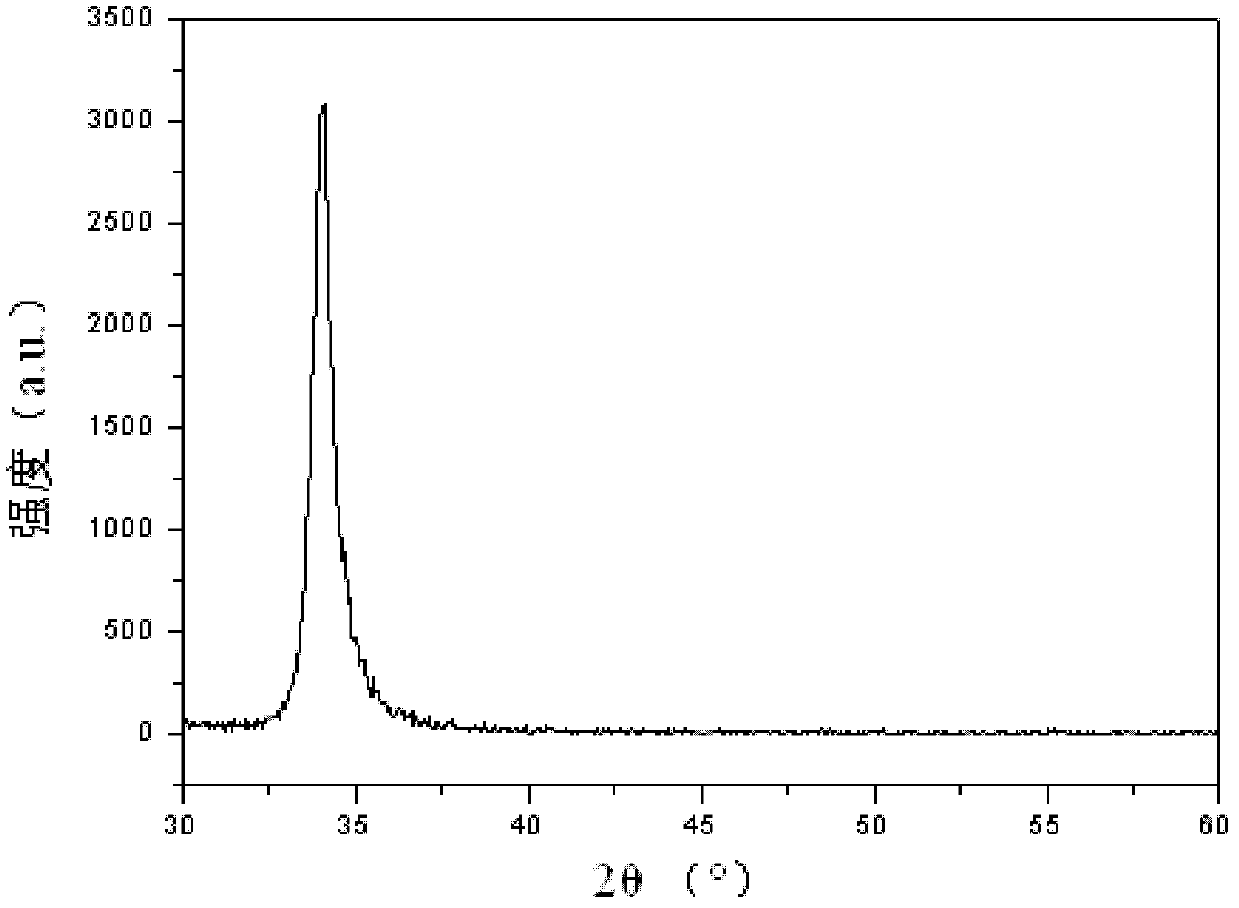

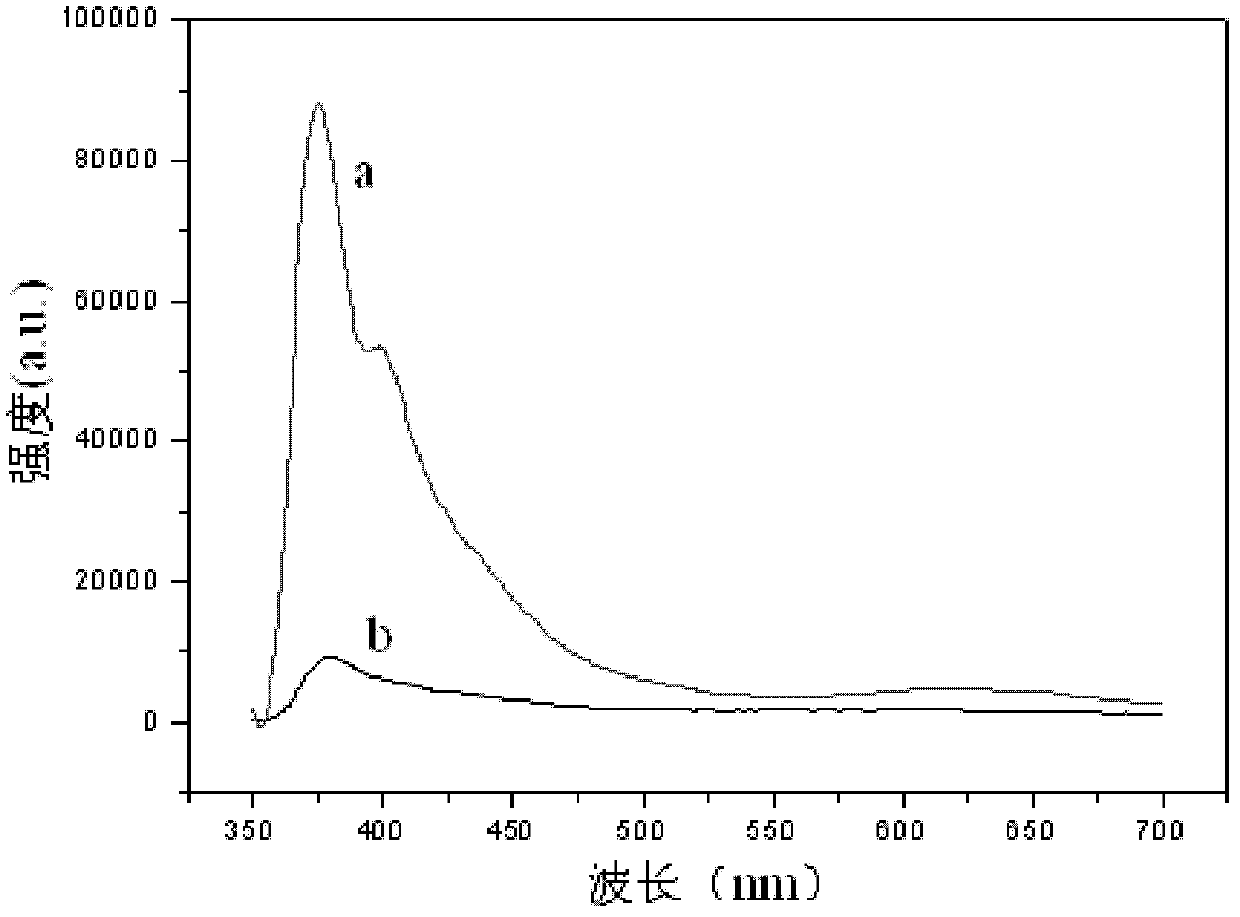

[0016] Embodiment 1: The Ag, Ga, N-doped ZnO thin film with multi-light region light emission in this embodiment is sputtered a layer of Ag, Ga, N co-doped ZnO thin film on the substrate.

[0017] In the present embodiment, the Ag, Ga, and N-doped ZnO thin film with multi-light regions emits light, and the Ag, Ga, and N double-acceptor-donor co-doped ZnO thin film is magnetron sputtered on the substrate, and the doping elements Ga and N Regulate and control the luminescence of ZnO thin films in the violet band, while the doping of Ag increases the concentration of excitons on the one hand and promotes the O i The formation of the ZnO film effectively increases the luminous intensity of the ZnO film in the ultraviolet and visible light regions. On the other hand, it increases the concentration of the neutral donor-bound excitons in the ZnO film. Luminous peak. When doping, due to the high formation energy of N, it is not easy to be mixed into the ZnO lattice. The present inven...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment is different from Embodiment 1 in that the substrate is silicon or quartz glass. Others are the same as in the second embodiment.

specific Embodiment approach 3

[0019] Specific implementation mode three: the preparation method of the multi-light area luminescent Ag, Ga, N-doped ZnO thin film of the present embodiment is carried out according to the following steps:

[0020] 1. Preparation of target material: Weigh 99.1% to 99.6% of ZnO powder and 0.9% to 0.4% of Ga 2 o 3 Mix the powder evenly, add it into the mold, and press it for 4-6 hours at a temperature of 1000°C-1300°C and a pressure of 5-20MPa to obtain a ceramic sheet with a diameter of 60mm-100mm and a thickness of 3mm-5mm. The Ag sheet, which accounts for 1% to 2% of the ceramic sheet area, is attached to the center of the ceramic sheet to obtain the target; the purity of the ZnO powder is ≥99.99%, the particle size is 0.2 μm to 2 μm, and the Ga 2 o 3 The purity of the powder is ≥99.99%, and the particle size is 0.2 μm to 2 μm;

[0021] 2. Put the target and substrate prepared in step 1 into a radio frequency magnetron sputtering coating machine, wherein the distance betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com