Blast furnace reducing tuyere short set

A technology of radial wind and blast furnace, applied in the direction of tuyere, etc., can solve the problems of short service life of tuyere small sleeve, inability to use on demand, and inability to increase air supply speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

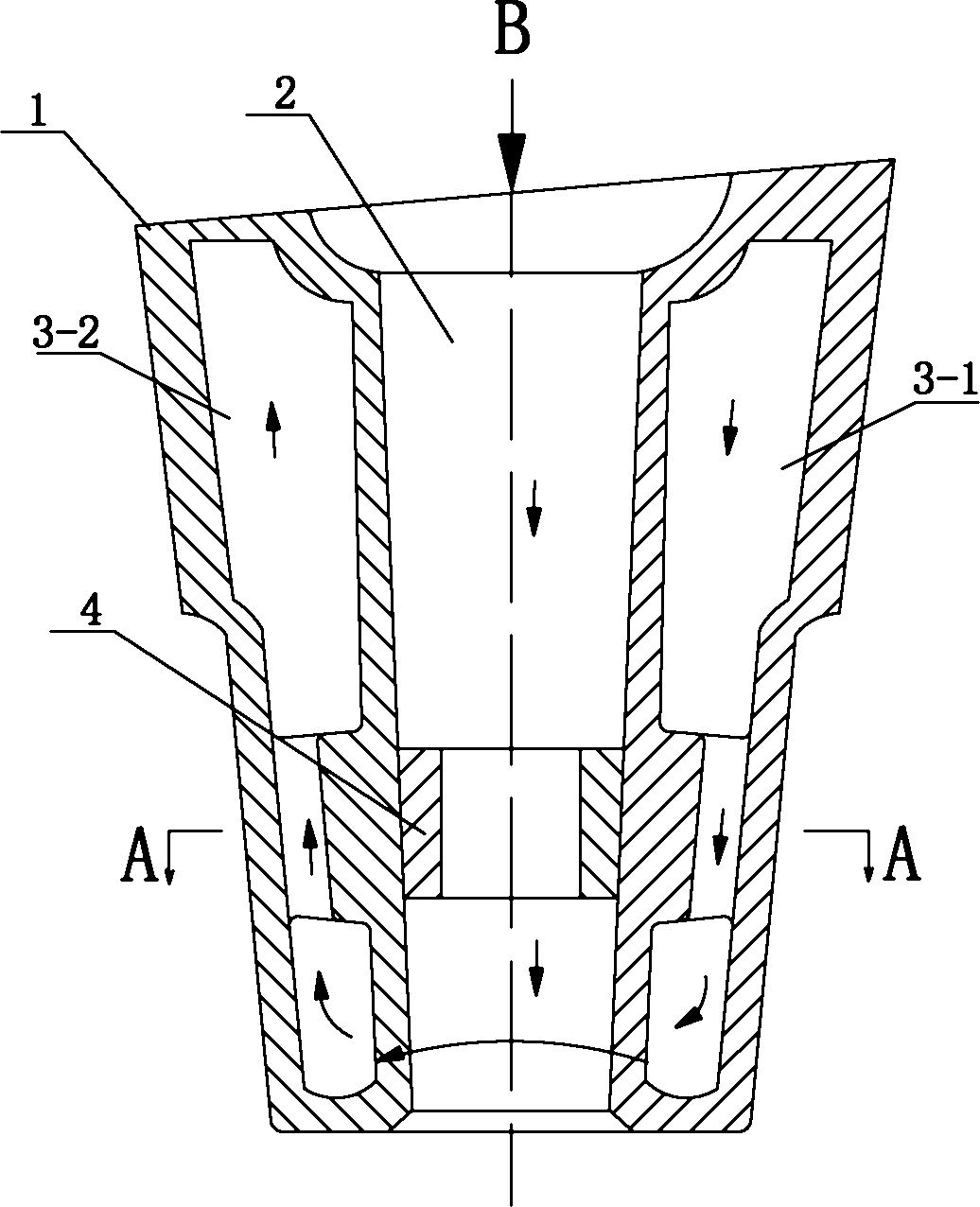

[0016] The basic structure of the blast furnace variable diameter tuyere small sleeve of the present embodiment is as follows: figure 1 As shown, it includes a small sleeve body 1 made of copper or ferrous metal that is basically in the shape of a circular table and has inlet and outlet ends. The tuyere is basically a circular platform-shaped air duct 2, and the air inlet and outlet of the air duct 2 correspond to the air inlet and outlet respectively. The cross-sectional area of the air inlet of the air duct 2 is larger than the cross-sectional area of the air outlet;

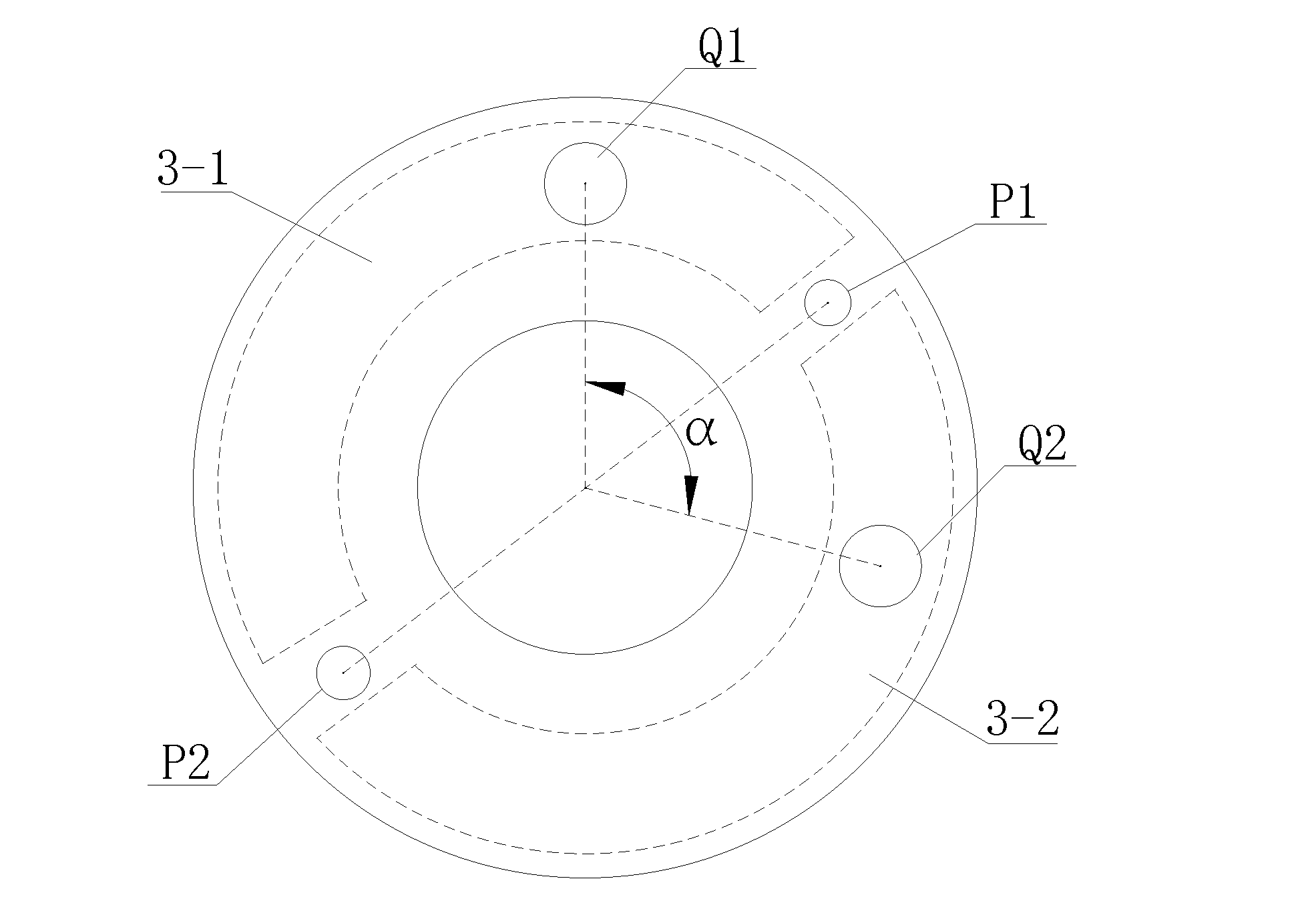

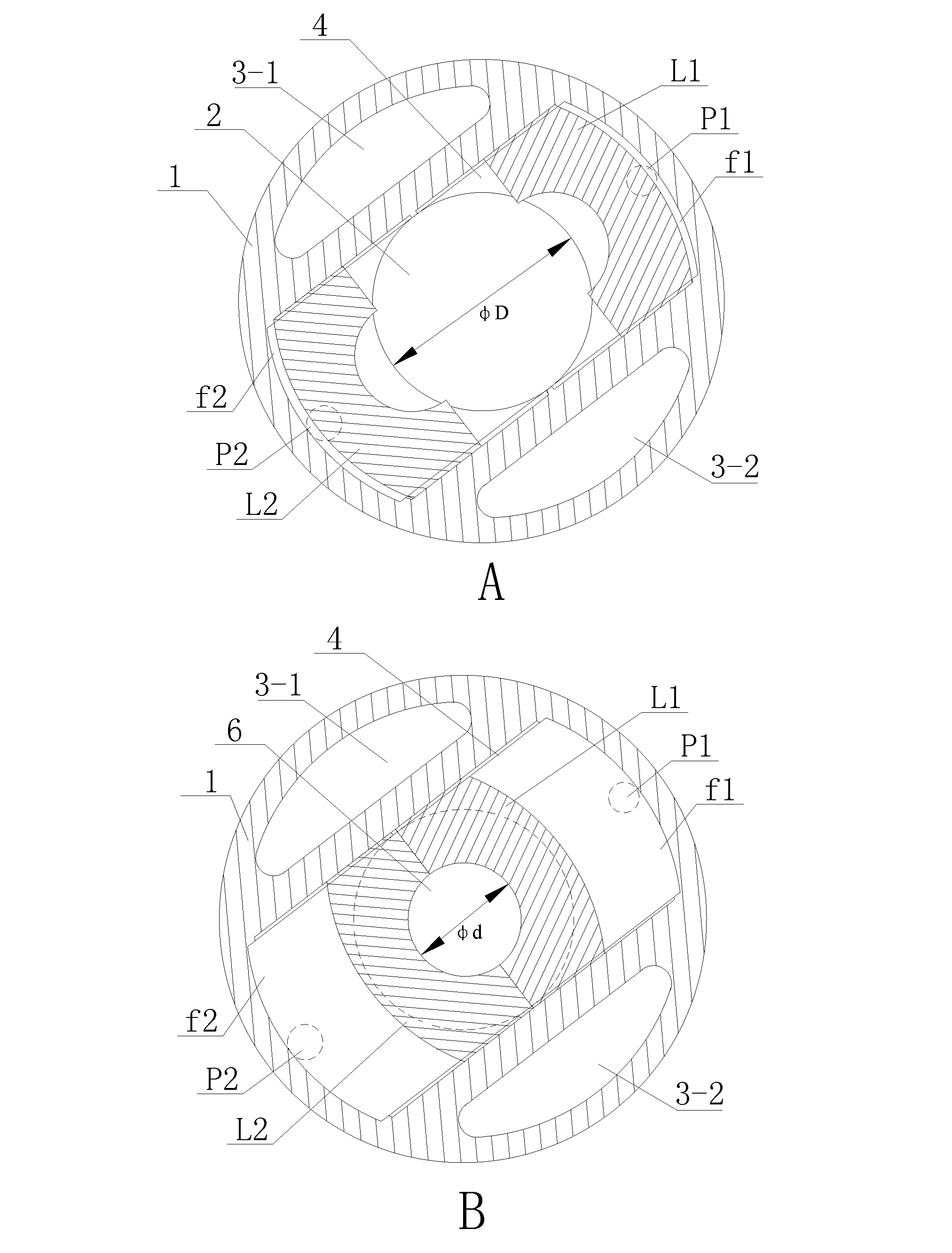

[0017] A valve cavity 4 is provided between the middle part of the small sleeve main body 1 and the air outlet end. Such as figure 2 As shown, the valve cavity 4 is formed by the air duct 2 expanding radially towards the small sleeve body 1 at the same time. The two control holes P1 and P2 at the end; the valve cavity 4 is equipped with a pair of throttle valve cores L1 and L2 respectively located on b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com