Sulfoacid/carboxylic acid type hydrophilic chain extender and preparation method thereof

A technology of hydrophilic chain extender and carboxylic acid type, which is applied in the field of water-based polyurethane hydrophilic chain extender and its preparation, can solve the problems of few types and single performance, and achieve cheap price, easy raw materials and simple process route Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

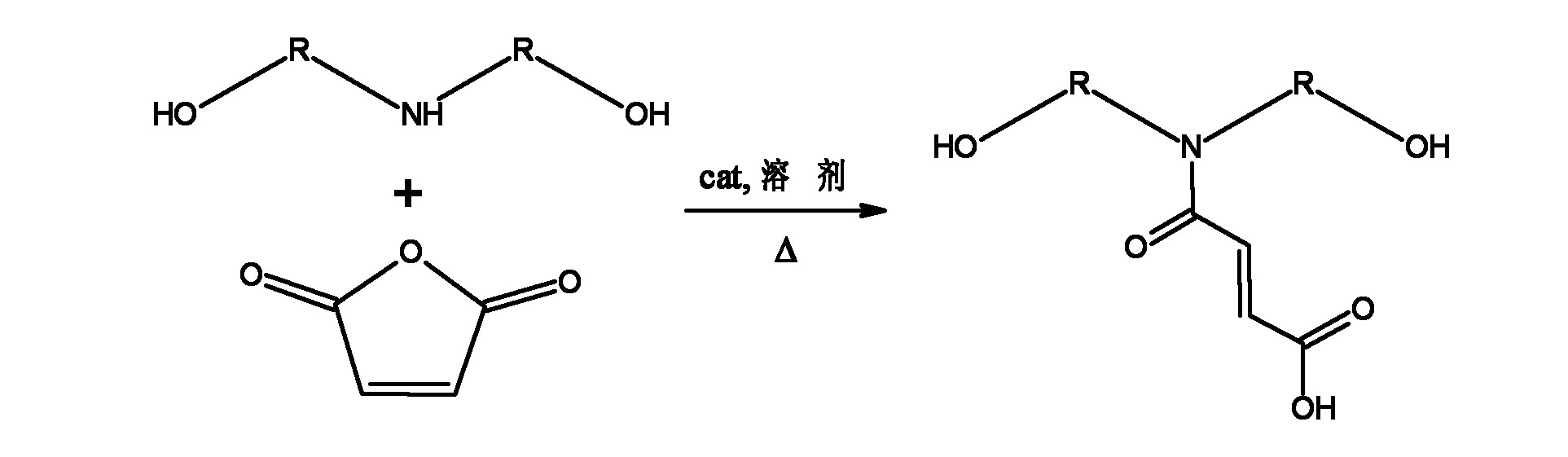

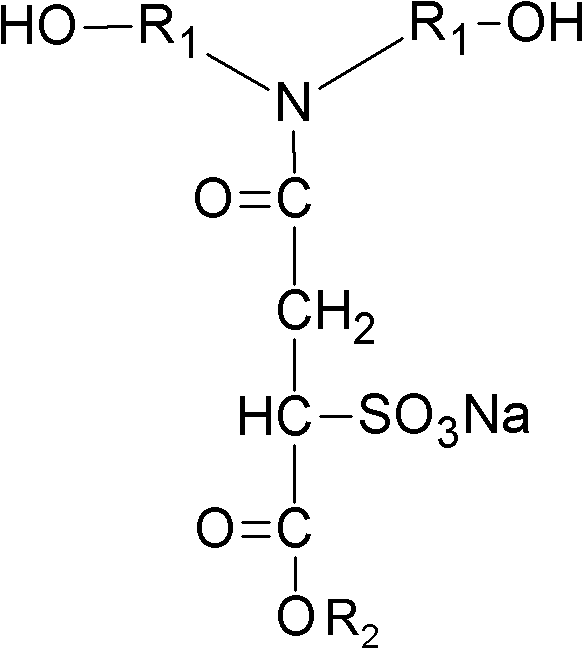

[0022] 1) Amidation reaction:

[0023] see figure 1 99 parts by mass of maleic anhydride are dissolved in 45 parts of acetone to make solvent A, 107 parts by mass of diethanolamine are dissolved in 40 parts of acetone to make solution B, and the solution A is added to the reactor with nitrogen protection, reflux condenser, stirrer, and dropping funnel, and 0.5 parts of catalyst N,N-lutidine is added to the reactor, and the reaction temperature is controlled at 50°C , slowly add solution B into the reactor, fully react under stirring, then distill off the solvent under reduced pressure to obtain a white powder, then recrystallize with ethanol, then filter and dry the crystal to obtain a white powder, the white powder is Amidation intermediate for the reaction of sulfonic acid / carboxylic acid type hydrophilic chain extender;

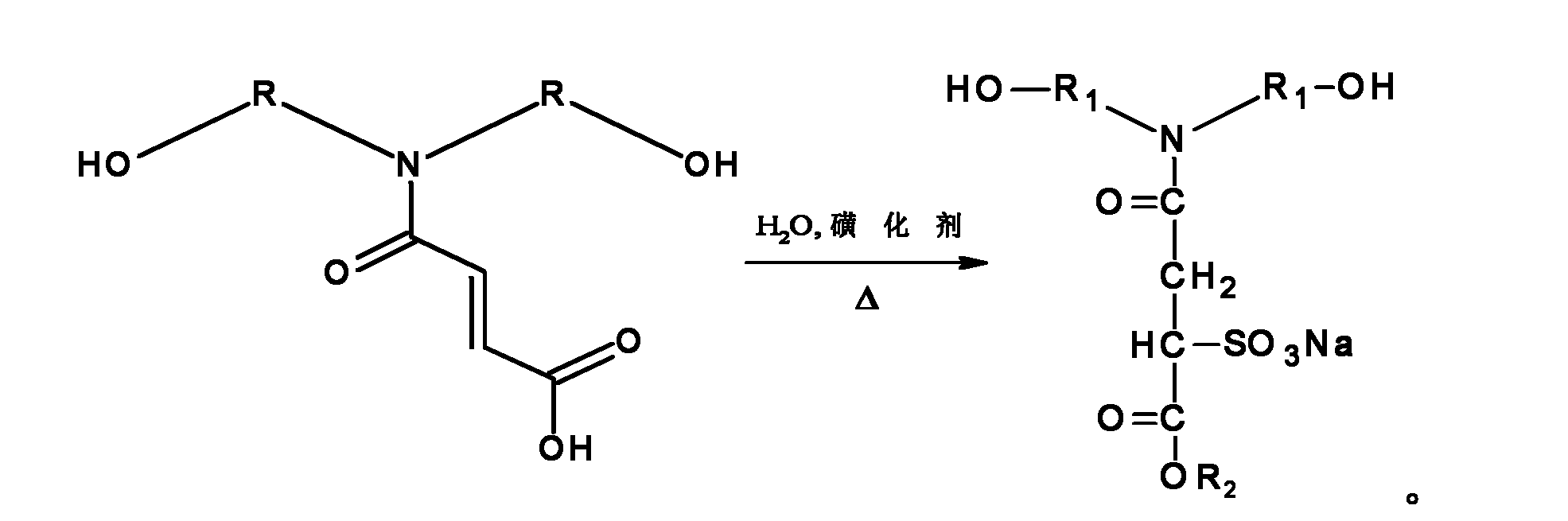

[0024] 2) Sulfonation reaction:

[0025] see figure 2 , take 100 parts of white powder amidation reaction intermediate and 62 parts of sulfonating ag...

Embodiment 2

[0030] 1) Amidation reaction:

[0031] Get 99 parts by mass of maleic anhydride and dissolve in 50 parts of butanone to make solvent A, get 134 parts by mass of diisopropanolamine and dissolve in 45 parts of butanone to make a solution B. Add solution A to the reactor with nitrogen protection, reflux condenser, stirrer, and dropping funnel, control the reaction temperature at 60°C, slowly add solution B to the reactor, and stir it moderately After sufficient reaction under reduced pressure, the solvent was distilled off to obtain a white powder, which was recrystallized with ethanol, and then the crystal was filtered and dried to obtain a white powder, which was the reaction of sulfonic acid / carboxylic acid type hydrophilic chain extender. amidation intermediates;

[0032] 2) Sulfonation reaction:

[0033] Take 100 parts of white powder amidation reaction intermediate and 45 parts of sulfonating agent sodium bisulfite dissolved in water, add to the reactor, stir well, raise ...

Embodiment 3

[0035] 1) Amidation reaction:

[0036] Get 99 parts by mass of maleic anhydride and dissolve in 190 parts of chloroform to make solvent A, get 107 parts by mass of diethanolamine and dissolve in 180 parts of chloroform to make solution B, and dissolve solution A Add to the reactor with nitrogen protection, reflux condenser, stirrer, dropping funnel, and add 0.5 parts of catalyst N, N-lutidine to the reactor, the reaction temperature is controlled at 80 °C, Slowly add solution B into the reactor, fully react under moderate stirring, and then distill off the solvent under reduced pressure to obtain a white powder, then recrystallize with ethanol, then filter and dry the crystal to obtain a white powder, the white powder is Amidation intermediate for the reaction of sulfonic acid / carboxylic acid type hydrophilic chain extender;

[0037] 2) Sulfonation reaction:

[0038] Take 100 parts of white powder amidation reaction intermediate and 45 parts of sulfonating agent sodium bisul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com