Synthetic method and application of epoxy vinyl ester resin with high bromine content

A technology of epoxy vinyl ester and synthesis method, which is applied in the field of synthetic resin flame retardant additives, can solve the problems of reduced mechanical properties, unstable flame retardant effect of additive type flame retardants, difficult molding, etc., and achieves convenient operation and thermal deformation. Effect of elevated temperature, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

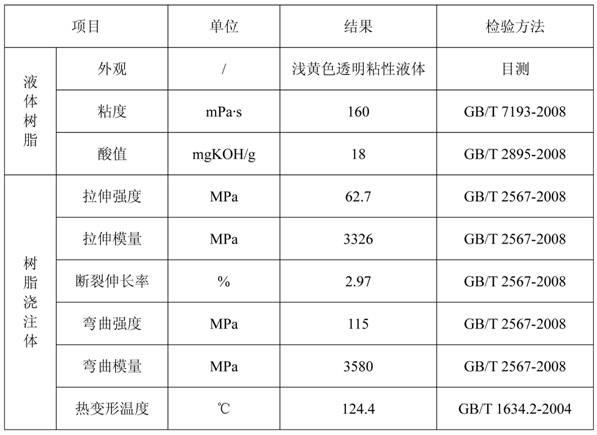

Embodiment 1

[0025] Drop into high bromine content EX-48 bisphenol A epoxy resin 600g in 1000ml there-necked flask with thermometer, stirrer, condenser, methacrylic acid 105g, fumaric acid 11.6g, hydroquinone 0.35g, N, 3.5g of N'-dimethylaniline, heated to 80°C-90°C, stirring at the same time, measuring the acid value at intervals, until the acid value is less than 30mgKOH / g as the end point of the reaction, stop the reaction. Cool the reaction product below 100°C, add 320g of styrene, stir and cool to room temperature to obtain epoxy vinyl ester resin with high bromine content.

Embodiment 2

[0027] Put 600g of high bromine content EX-48 bisphenol A epoxy resin, 120g of methacrylic acid, 0.35g of hydroquinone, and 3.5g of tetramethylammonium chloride into a 1000ml three-necked flask equipped with a thermometer, agitator and condenser , heat up to 90°C to 100°C while stirring, measure the acid value at intervals until the acid value is less than 30mgKOH / g as the end point of the reaction, stop the reaction. Cool the reaction product below 100°C, add 160g of styrene and 160g of vinyl toluene, stir and cool to room temperature to obtain epoxy vinyl ester resin with high bromine content.

Embodiment 3

[0029] In a 1000ml three-necked flask equipped with a thermometer, a stirrer and a condenser, 500g of high bromine content CYDB-400 bisphenol A epoxy resin, 101g of methacrylic acid, 11.6g of fumaric acid, 0.35g of methyl p-phenol, benzyl Triethylammonium chloride 3.0g, heat up to 90°C-100°C, stir at the same time, measure the acid value at intervals, until the acid value is less than 30mgKOH / g as the end point of the reaction, stop the reaction. Cool the reaction product to below 100°C, add 350g of styrene, stir and cool to room temperature to obtain epoxy vinyl ester resin with high bromine content.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com