Long-service-life lining material for whole pipeline of large and medium sized blast furnace hot blast stove

A hot blast stove and long-life technology, applied in the field of blast furnace pipe lining materials and refractory materials, can solve the problems of easy cracking, deformation, and collapse of lining materials, and achieve good thermal shock stability, good toughness and expansion stability , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

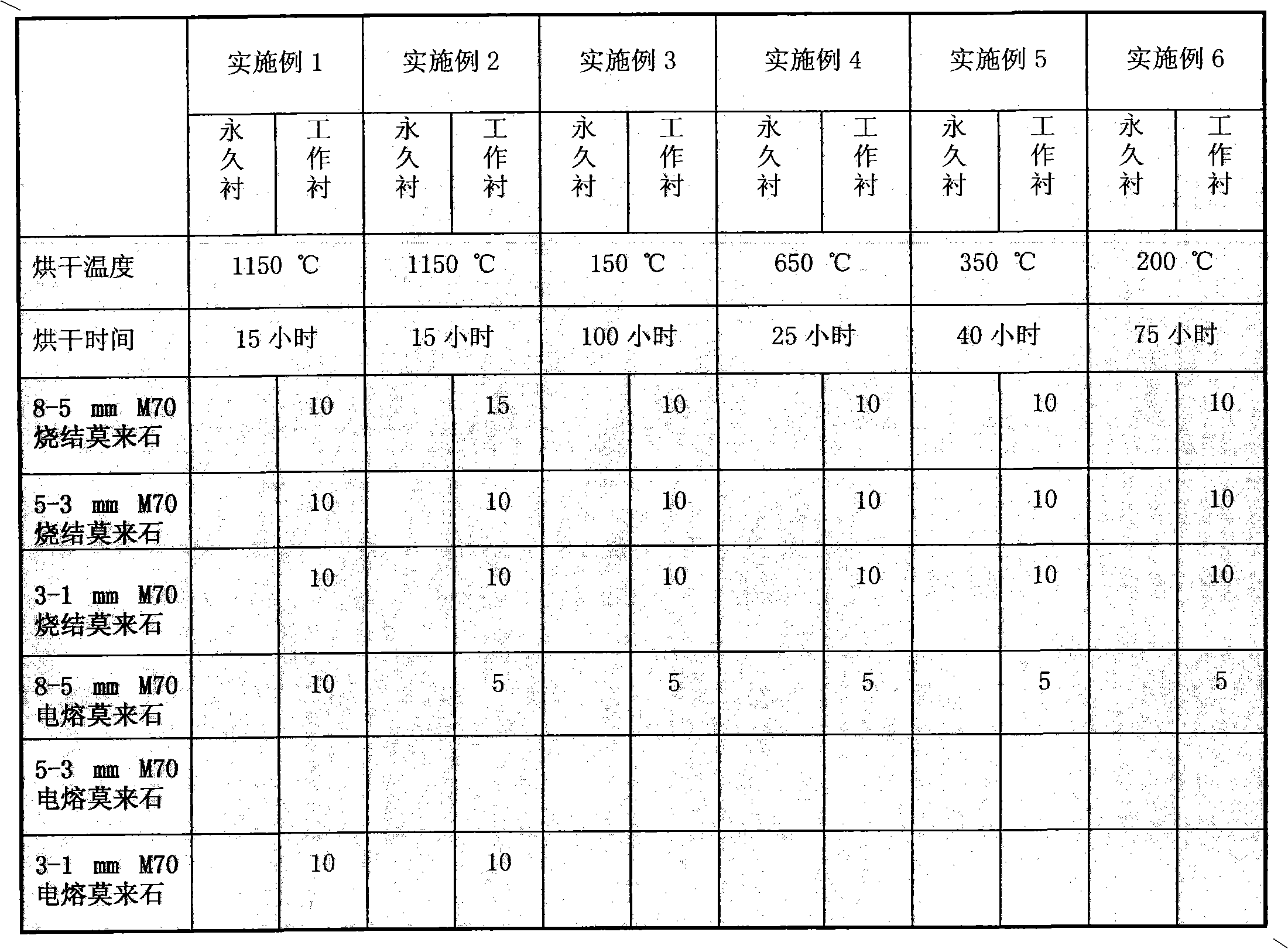

Embodiment 1

[0027] A long-life integrated pipeline lining material for large and medium-sized blast furnace hot blast stoves, which includes a permanent lining and a working lining. The permanent lining is formed by pouring the base material with the following components and contents and baking at 150°C for 100 hours , the base material contains 40wt% of microporous aggregate with a particle size of 5mm or less, 10wt% of polypropylene balls with a particle size of 0.2mm or less, 20wt% of primary alumina with a particle size of 0.074mm or less, and α-oxidized spheres with a particle size of 0.001mm or less. 6wt% aluminum, 6wt% silica powder with a particle size below 0.001mm, 10wt% calcined kaolin with a particle size below 0.074mm, and 8wt% CA80 cement;

[0028] The working lining is formed by pouring the base material with the following components and content and baking at 150°C for 100 hours. The base material contains 10wt% of 8-5mm M70 sintered fused mullite with a particle size of 5 ...

Embodiment 2

[0030] A long-life integrated pipeline lining material for large and medium-sized blast furnace hot blast stoves, which includes a permanent lining and a working lining. The permanent lining is formed by pouring the base material with the following components and contents and baking at 1150°C for 15 hours , the base material contains 50wt% of microporous aggregate with a particle size of 5mm or less, 10wt% of polypropylene balls with a particle size of 0.2mm or less, 10wt% of primary alumina with a particle size of 0.074mm or less, and α-oxidized spheres with a particle size of 0.001mm or less. 6wt% of aluminum, 6wt% of silica powder with a particle size of 0.001mm or less, 10wt% of calcined kaolin with a particle size of 0.074mm or less, 7.97wt% of CA80 cement and 0.03wt% of sodium tripolyphosphate;

[0031] The working lining is made by pouring the base material with the following components and content and baking at 1150°C for 15 hours. The base material contains 15 wt% of 8...

Embodiment 3

[0033] A long-life integrated pipeline lining material for large and medium-sized blast furnace hot blast stoves, which includes a permanent lining and a working lining. The permanent lining is formed by pouring the base material with the following components and contents and baking at 150°C for 100 hours , the base material contains 55wt% of microporous aggregate with a particle size of 5mm or less, 12wt% of polypropylene balls with a particle size of 0.2mm or less, 13wt% of primary alumina with a particle size of 0.074mm or less, and α-oxidized spheres with a particle size of 0.001mm or less. 3wt% of aluminum, 5wt% of silica powder with a particle size of 0.001mm or less, 7wt% of calcined kaolin with a particle size of 0.074mm or less, 4.97wt% of CA80 cement and 0.03wt% of sodium tripolyphosphate;

[0034] The working lining is formed by pouring the base material with the following components and content and baking at 150°C for 100 hours. The base material contains 10wt% of 8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com