X-spiral-flow wound membrane diversion screen

A roll-type membrane and separator technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., to achieve the effects of enhancing the mass transfer capacity of the raw liquid, reducing the contact, and increasing the effective use area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

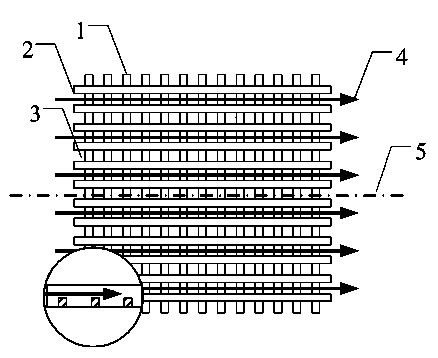

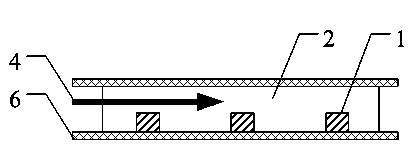

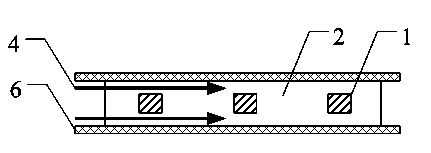

[0032] The embodiment will be further described in conjunction with the accompanying drawings, as Figure 5 to Figure 9 As shown, the X swirl roll membrane diversion screen of the present invention is composed of a lower flow channel 9 and an upper flow channel 10, the upper flow channel 10 is composed of a plurality of upper longitudinal ribs 8 parallel to each other, and the lower flow channel 9 is composed of multiple The lower longitudinal ribs 7 of the strips are parallel to each other. The flow direction of the raw liquid in the flow channel constitutes the vector direction of the flow channel. The axial line 5 is the projection of the central axis of the roll film on the diversion screen. The axial line 5 is parallel to the central axis of the roll film, which is used to illustrate the flow guide The virtual line of the grid structure. The angle between the lower longitudinal rib 7, the upper longitudinal rib 8 and the axial line 5 are greater than and less than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com