Auxiliary material and method for preparing sliced dried beef by aid of auxiliary material

A technology of beef jerky and auxiliary materials, applied in the fields of application, food preparation, food science, etc., can solve the problems of destroying the flavor and taste of beef, high energy consumption in production, poor chewiness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

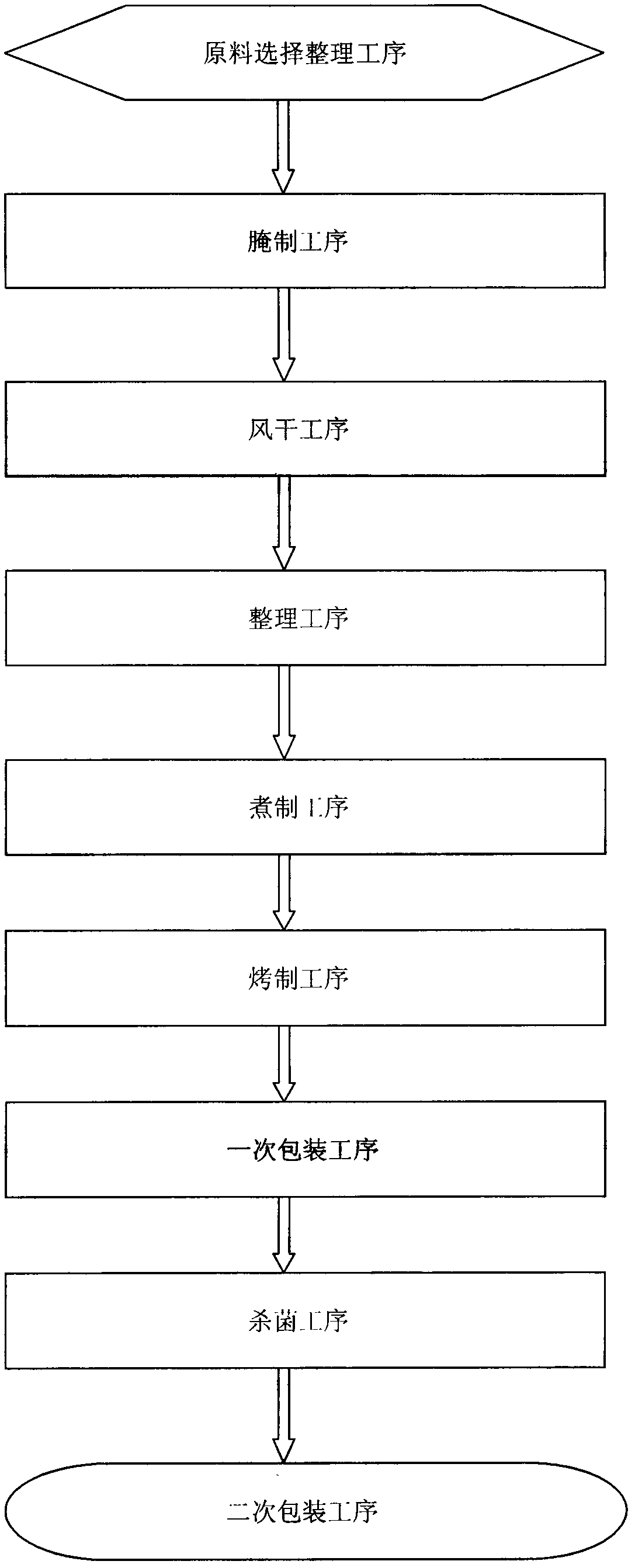

[0098] We utilize above-mentioned auxiliary material to make a kind of original flavor beef jerky, the method for making this beef jerky comprises the following steps:

[0099] A. Raw material selection and finishing process

[0100] Select 50,000 grams of frozen beef that has passed the health and quarantine, and thaw it completely after 24 hours; after thawing, remove the fascia, blood stains, fat and other sundries of the beef, and clean it; cut the beef into strips of 2*3*N cm, 10 Centimeter≤N≤30cm, as uniform as possible;

[0101] B. Pickling process

[0102] Put the beef strips prepared in step A in the curing tank, pour the seasoning soup prepared with 60,000 grams of water, 440 grams of salt, 30 grams of auxiliary materials, 50 grams of monosodium glutamate, 25 grams of white sugar, and 25 grams of white wine into the curing tank. Stir well, and marinate at room temperature for 10 hours;

[0103] C. Air drying process

[0104] Hang the marinated beef strips in step...

Embodiment 2

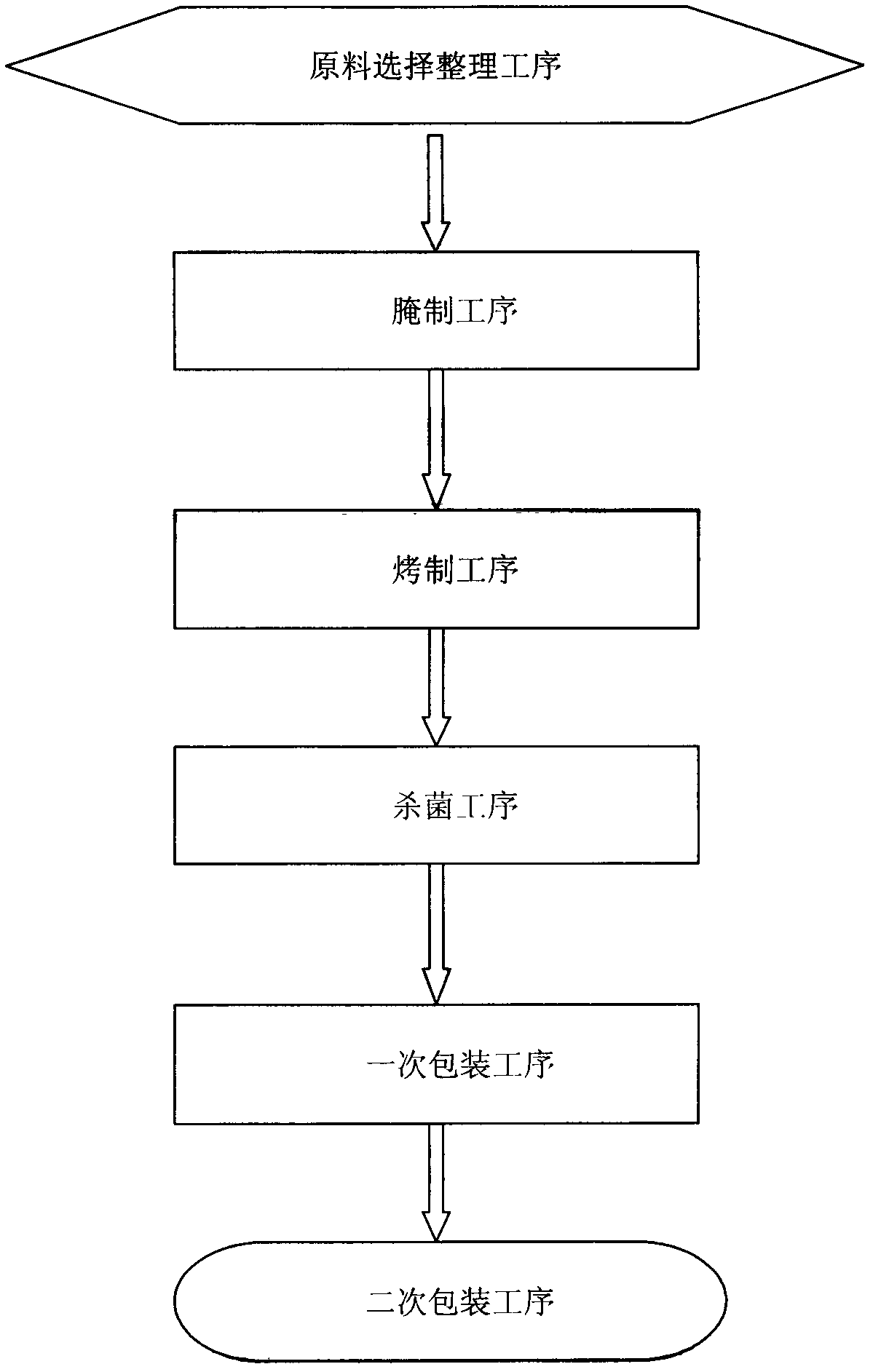

[0121] We utilize above-mentioned auxiliary material to make a kind of roast beef jerky, the method for making this beef jerky comprises the following steps:

[0122] A. Raw material selection and finishing process

[0123] Select 50,000 grams of frozen beef that has passed the sanitary quarantine, and thaw it completely for 24 hours; remove the fascia, blood stains, fat and other sundries of the beef, and clean it; cut the beef into strips of 1.5*2*N cm, 3 cm ≤ N≤3.5cm;

[0124] B. Pickling process

[0125] Put the prepared beef in step A in the marinating tank, pour 60,000 grams of water, 440 grams of salt, 30 grams of auxiliary materials, 50 grams of monosodium glutamate, 25 grams of white sugar, and 25 grams of white wine into the marinating tank. Stir well and marinate at room temperature for 10 hours;

[0126] C. Baking process

[0127] Hang the marinated beef strips in step B into the drying room for high-temperature baking. The baking temperature is set at 68°C for...

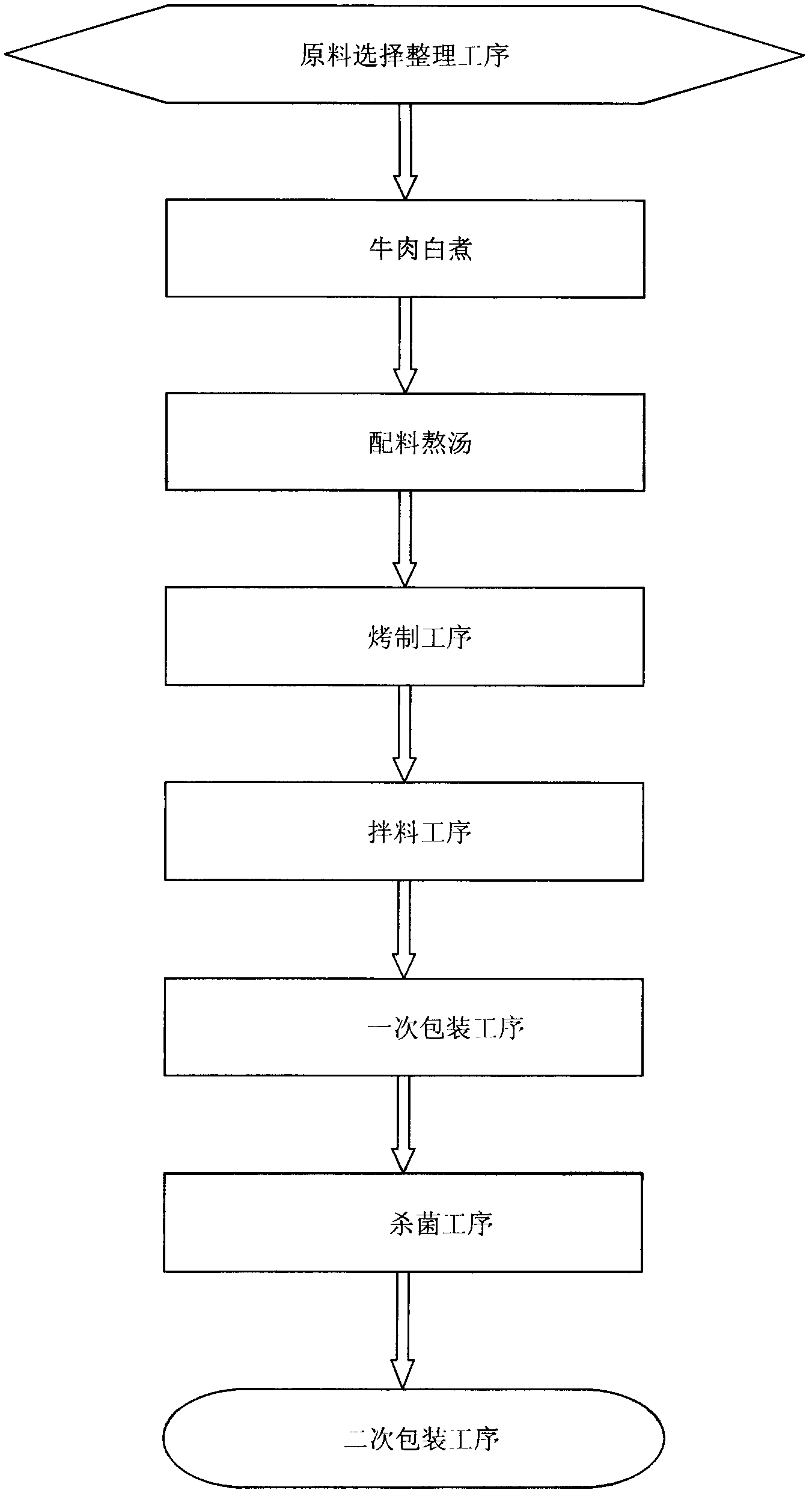

Embodiment 3

[0137] We utilize above-mentioned auxiliary material to make a kind of hot and spicy beef jerky, the method for making this beef jerky comprises the following steps: in this method, the weight ratio of beef and auxiliary material; when beef is calculated according to 100000 grams, use auxiliary material 30 grams;

[0138] A. Raw material selection and finishing process

[0139] Choose 100,000 grams of frozen beef that has passed the health and quarantine, and thaw it completely within 24 hours; remove fascia, blood stains, fat and other sundries from the thawed beef, and clean it; cut the beef into 500-1000 grams of beef cubes, and try to be as uniform as possible;

[0140] B. Precooked beef

[0141] Boil the beef that has been cut into pieces in step A with clean water, skim off the foam and floating oil, boil for 10 minutes, remove, and after the beef is completely cooled, cut into cubes and remove the fat;

[0142] C. Cook soup with ingredients

[0143] The weight ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com