Self-supporting flexible carbon nano-tube paper composite electrode material for lithium ion battery

A technology of carbon nanotube paper and lithium-ion batteries, which is applied in the fields of chemical engineering and energy and chemical engineering, to achieve the effects of promoting progress and development, improving performance, and avoiding capacity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

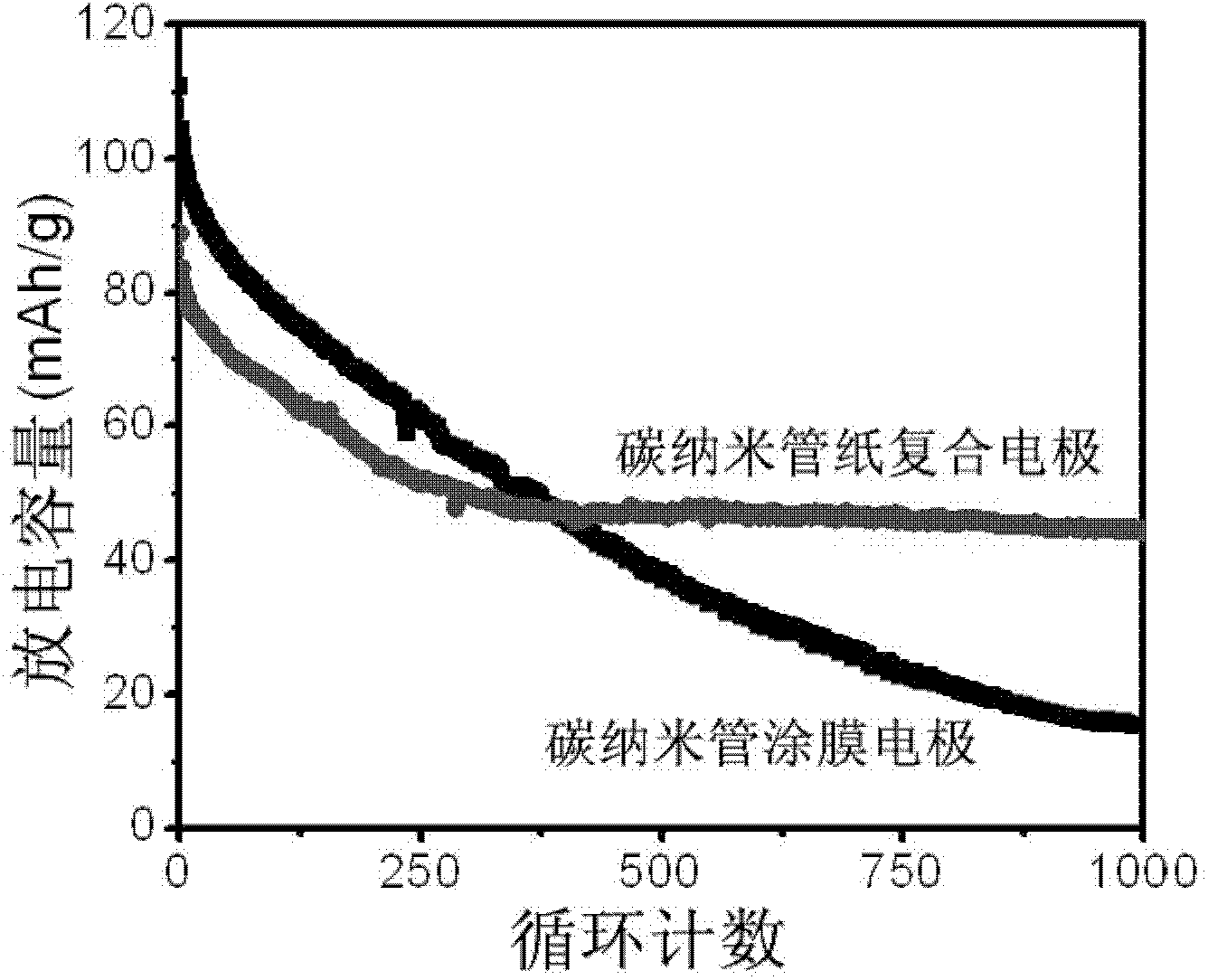

[0028] Carbon nanotubes with a diameter of 10 nanometers and a length of 50 micrometers prepared by the fluidized bed chemical vapor deposition process and vermiculite as a catalyst are used as raw materials; commercial LiFePO 4(particle size is 100 nanometers) is a positive electrode active material assembly carbon nanotube paper composite electrode material. Carbon nanotubes and lithium iron phosphate (LiFePO 4 ) particles were shear dispersed in 100mL N-methylpyrrolidone (carbon nanotube concentration 1mg / mL, LiFePO 4 Particle concentration 4mg / mL). Carbon nanotube paper / LiFePO was obtained on filter paper by vacuum filtration 4 The particle composite material can remove the carbon nanotube paper from the filter paper by drying. The carbon nanotube paper composite electrode has good flexibility and can undergo large elastic deformation under external force. The mass ratio of carbon nanotubes to active materials in the electrodes is 1:4. Scanning electron microscope obse...

Embodiment 2

[0030] The carbon nanotubes obtained by the planktonic chemical vapor deposition process are used as raw materials, with a diameter of 100 nanometers and a length of 1000 microns; cobalt oxide and lithium carbonate are used as raw materials, weighed according to the molar ratio of Li:Co=1:1, and mixed with carbon nanotubes Tube mixing for air shear dispersion. Perform high-temperature solid-phase synthesis at a high temperature of 800-900°C to obtain lithium cobaltate (LiCoO 2 ) particle / carbon nanotube composite structure, LiCoO 2 The particle size is 1 micron. The carbon nanotube composite material is placed in dimethylformamide for liquid phase shear dispersion, and the carbon nanotube paper material is obtained by filtering, and the carbon nanotube paper composite electrode material can be removed from the filter paper after drying. Next, the carbon nanotubes and LiCoO in the composite electrode 2 The mass ratio of the particles is 1:0.1, which exhibits excellent mechan...

Embodiment 3

[0032] The carbon nanotube obtained by thermal chemical vapor deposition process is used as a raw material, and the diameter of the carbon nanotube is 1 nanometer and the length is 0.5 micrometer. The carbon nanotubes were dispersed in FeSO through a liquid phase shearing process 4 In the solution, in an environment with a pH of about 10, oxygen induction and air oxidation are successively adopted to obtain ferric oxide (Fe 3 o 4 ) / carbon nanotube composite, wherein the particle size of ferric oxide is 50 nanometers, obtained through suction filtration and washing with ferric oxide as the carbon nanotube paper composite electrode of the negative active material, carbon nanotubes and carbon nanotubes in the electrode material The mass ratio of ferroferric oxide is 1:10, and the capacity can still maintain 400mAh / g after 100 cycles at a discharge intensity of 0.1C, and the capacity decay is less than 25% compared with the initial capacity, showing good cycle performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com