Method for preparing silicon oxide (SiOx) / carbon (C) composite materials and prepared silicon carbon cathode materials for lithium ion battery

A negative electrode material, lithium battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of reducing the decomposition degree of electrolyte, and achieve the effect of improving electronic conductivity, broad market prospects, and high cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

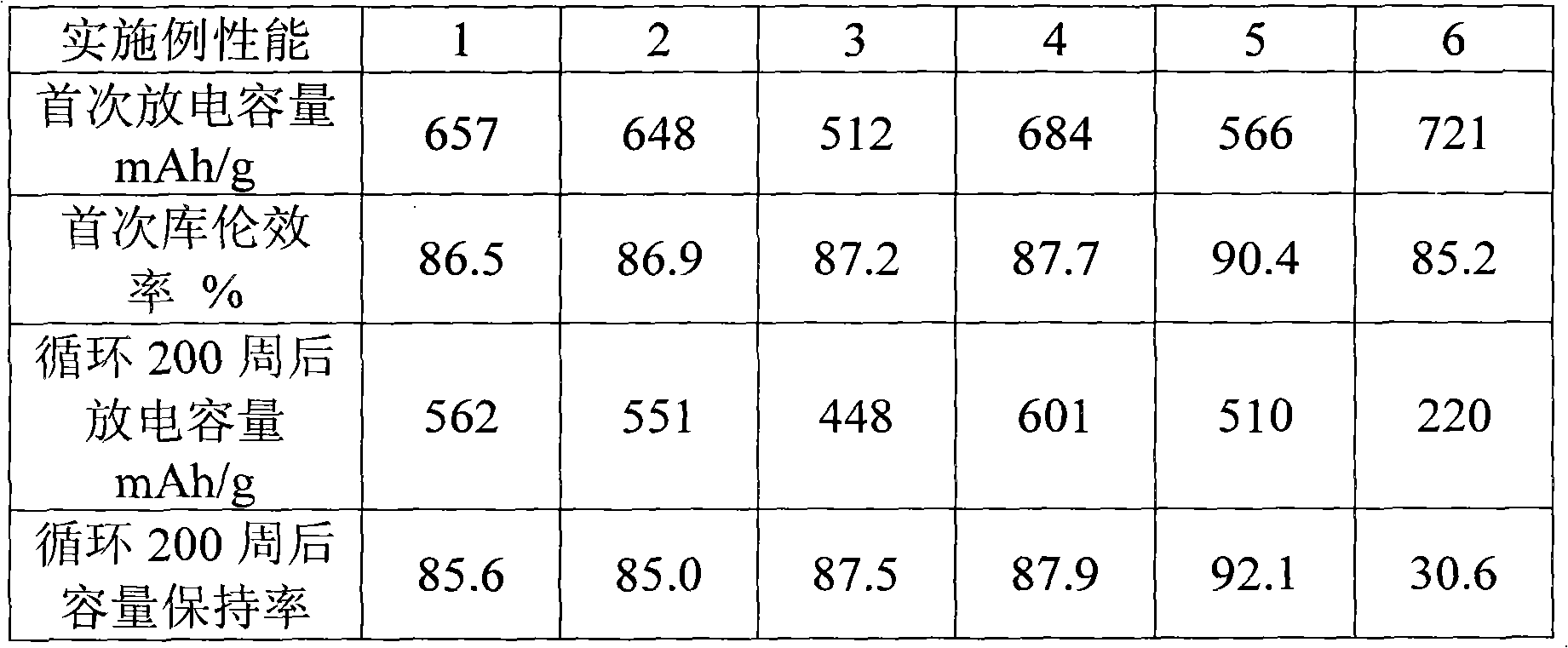

Examples

Embodiment 1

[0029] According to the following ratios: the molar ratio of absolute ethanol, deionized water and ammonia water is 2:2:1, the molar ratio of tetraethyl orthosilicate and absolute ethanol is 1:3, nano silicon powder, tetraethyl orthosilicate and The molar ratio of ammonia water is 1:6:3, prepare two solutions of a and b respectively, mix and stir at constant temperature for 12 hours to obtain sol, wash with absolute ethanol, and centrifuge to obtain SiO x Microspheres. Add asphalt to pyridine at a mass volume ratio of 0.1 g / mL. Prepared SiO x The microspheres were slowly added to the organic solution of bitumen, SiO x The mass ratio of microspheres and asphalt is 4:1. React at 70°C for 3 hours and dry in air. Under the protection of nitrogen, the asphalt-coated SiO x The microspheres were placed in a tube furnace, heated to 800°C at a heating rate of 2°C / min, carbonized at a constant temperature for 3 hours, and cooled naturally to obtain SiO x / C material.

[0030] Pre...

Embodiment 2

[0032] According to the following ratios: the molar ratio of absolute ethanol, deionized water and ammonia water is 2:2:1, the molar ratio of tetraethyl orthosilicate and absolute ethanol is 1:3, nano silicon powder, tetraethyl orthosilicate and The molar ratio of ammonia water is 1:8:4, prepare two solutions of a and b respectively, mix and stir at constant temperature for 12 hours to obtain sol, wash with absolute ethanol, and centrifuge to obtain SiO x Microspheres. Add asphalt to pyridine at a mass volume ratio of 0.1 g / mL. Prepared SiO x The microspheres were slowly added to the organic solution of bitumen, SiO x The mass ratio of microspheres and asphalt is 4:1. React at 70°C for 3 hours and dry in air. Under the protection of nitrogen, the asphalt-coated SiO x The microspheres were placed in a tube furnace, heated to 800°C at a heating rate of 2°C / min, carbonized at a constant temperature for 3 hours, and cooled naturally to obtain SiO x / C material.

[0033] Pre...

Embodiment 3

[0035] According to the following ratios: the molar ratio of absolute ethanol, deionized water and ammonia water is 2:2:1, the molar ratio of tetraethyl orthosilicate and absolute ethanol is 1:3, nano silicon powder, tetraethyl orthosilicate and The molar ratio of ammonia water is 1:6:3, prepare two solutions of a and b respectively, mix and stir at constant temperature for 12 hours to obtain sol, wash with absolute ethanol, and centrifuge to obtain SiO x Microspheres. Add asphalt to pyridine at a mass volume ratio of 0.1 g / mL. Prepared SiO x The microspheres were slowly added to the organic solution of bitumen, SiO x The mass ratio of microspheres and asphalt is 1:1. React at 70°C for 3 hours and dry in air. Under the protection of nitrogen, the asphalt-coated SiO xThe microspheres were placed in a tube furnace, heated to 800°C at a heating rate of 2°C / min, carbonized at a constant temperature for 3 hours, and cooled naturally to obtain SiO x / C material.

[0036] Prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com