Manufacturing method of semiconductor device

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, manufacturing tools, etc., can solve the unavoidable problems of semiconductor device manufacturing cost, increase, cost increase, etc., and achieve the suppression of voids and poor connections Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

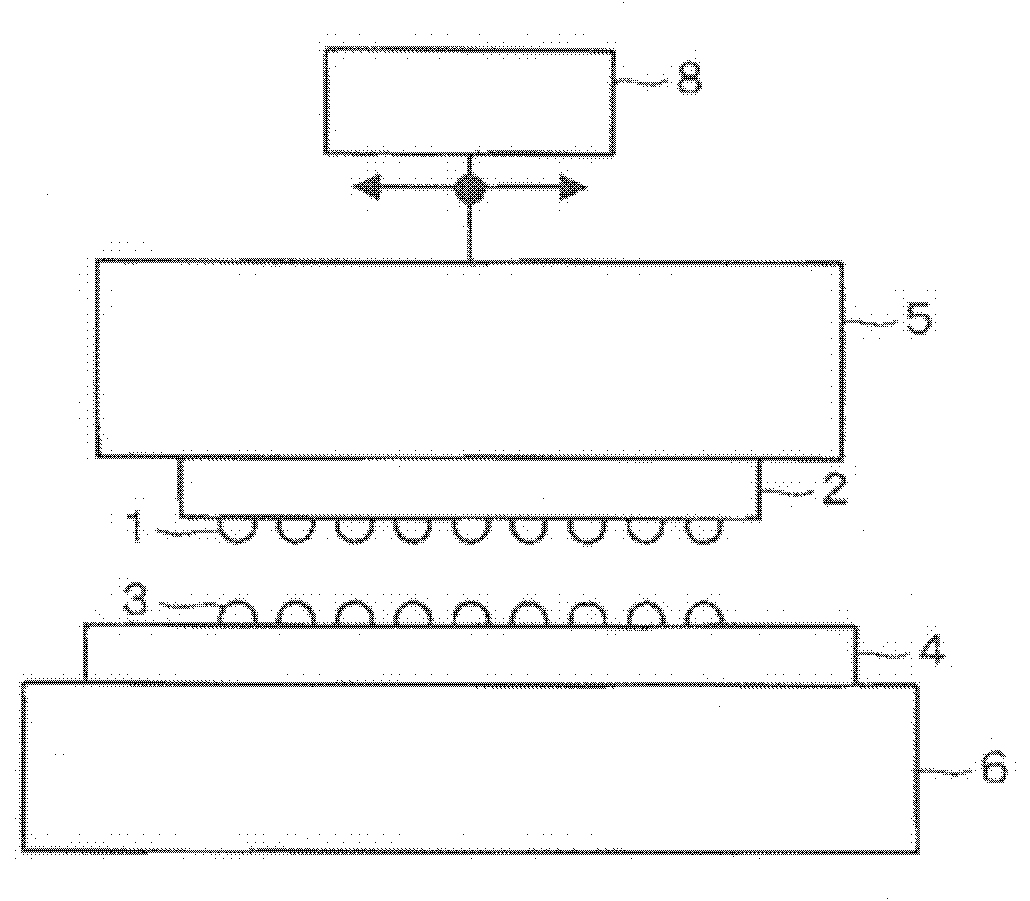

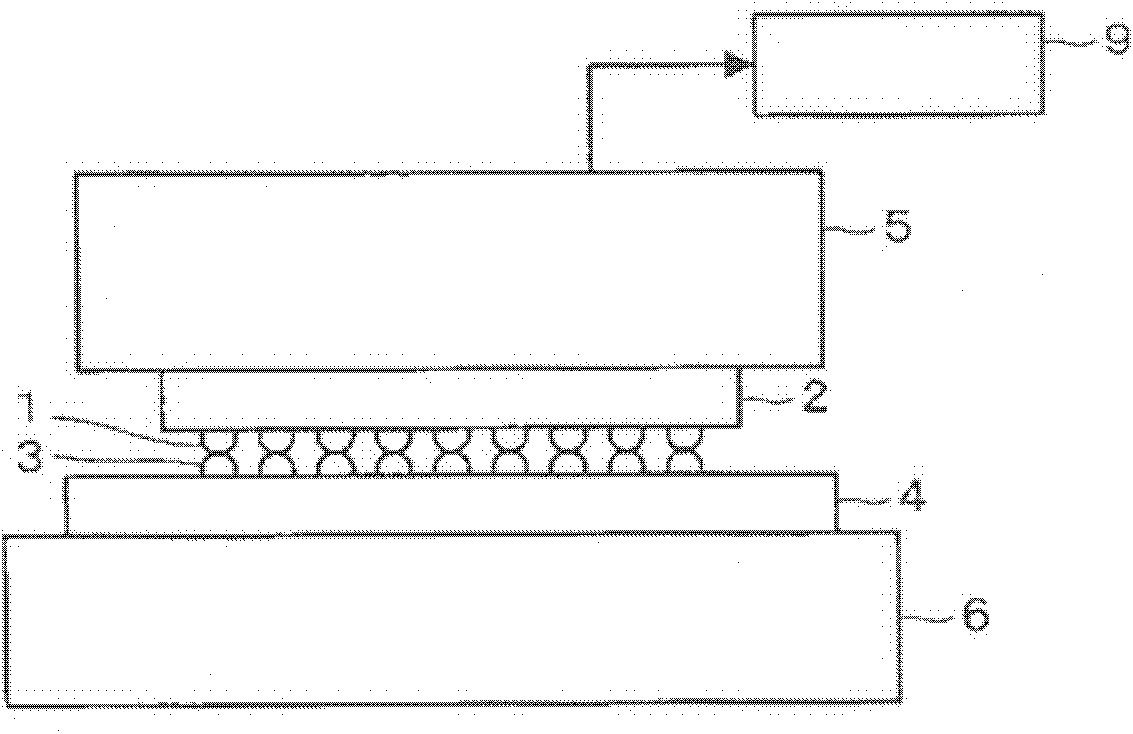

[0026] Figure 1 ~ Figure 4 It is a diagram showing the manufacturing process of the semiconductor device of the first embodiment. The first embodiment is a method of manufacturing a semiconductor device using flip chip connection without using flux. Such as figure 1 As shown, a first substrate 2 having first solder bumps 1 and a second substrate 4 having second solder bumps 3 are prepared. The first substrate 2 is sucked and held on the tool 5, for example. The second substrate 4 is arranged on the stage 6. From figure 1 The alignment process shown to image 3 The temporary connection process shown is implemented using a flip chip bonder having an alignment mechanism, a heating mechanism, and a height restriction mechanism.

[0027] The first substrate 2 and the second substrate 4 are, for example, semiconductor chips (silicon (Si) chips, etc.) or interposer chips (silicon (Si) interposers, etc.). The combination of the first substrate 2 and the second substrate 4 is, for exa...

no. 2 Embodiment approach

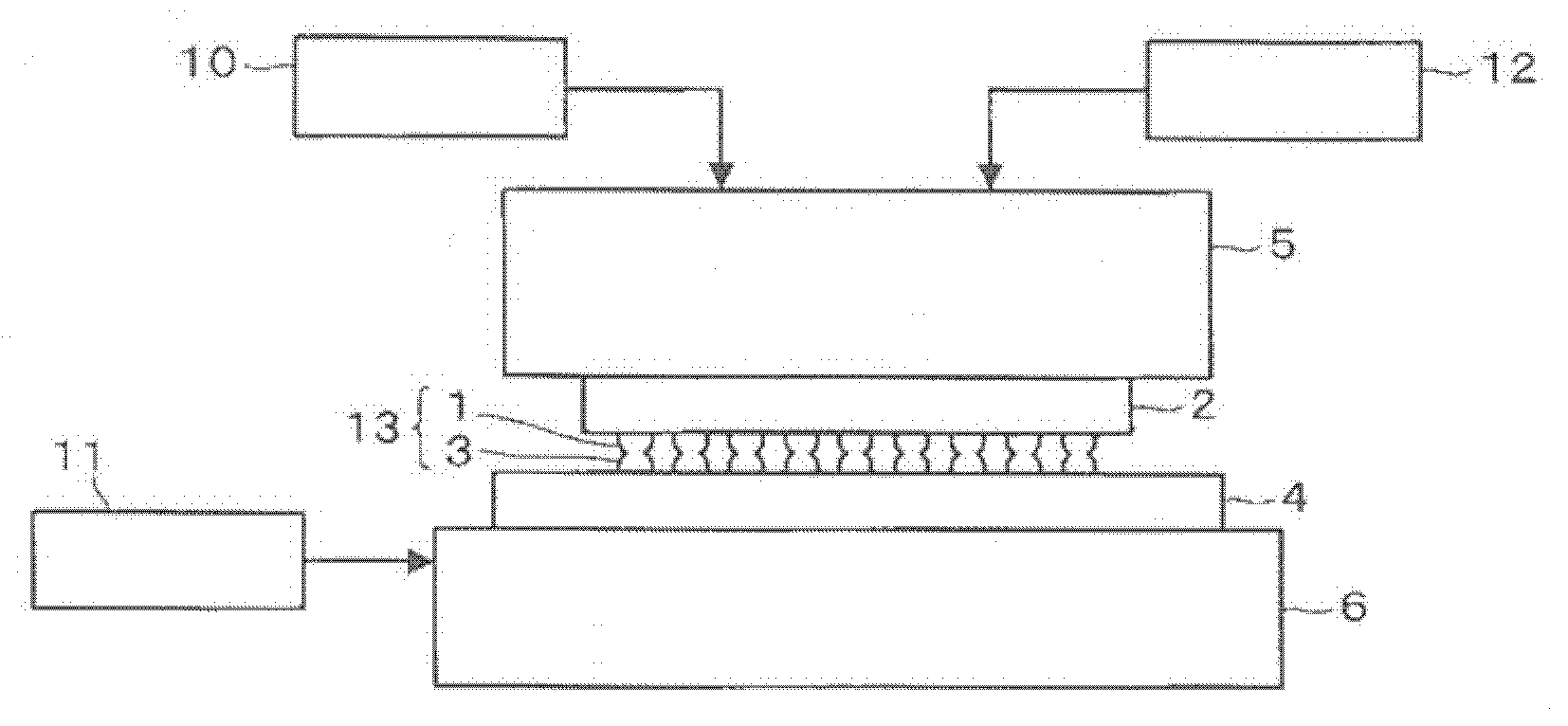

[0043] Figure 6 ~ Figure 9 It is a diagram showing the manufacturing process of the semiconductor device of the second embodiment. In the manufacturing process of the semiconductor device of the second embodiment, first, according to the same method as in the first embodiment, a first substrate 2 having first solder bumps 1 and a second substrate having second solder bumps 3 are prepared 4, such as Image 6 As shown, the first solder bump 1 and the second solder bump 3 are aligned. The specific examples of the substrates 2 and 4, the constituent materials of the solder bumps 1, 3, the alignment method of the solder bumps 1, 3, etc. are the same as those in the first embodiment. In addition, from Image 6 The alignment process shown to Picture 8 The temporary connection process shown is implemented using a flip chip bonder having an alignment mechanism, a pressure mechanism, a heating mechanism, an ultrasonic generating mechanism, and the like.

[0044] Then, like Figure 7 As...

Embodiment 1

[0052] First, a first semiconductor chip on which a solder bump composed of Sn-0.7% by mass Cu is formed on an electrode terminal by a plating method, and a second semiconductor chip on the connected side where the first solder bump is mounted are prepared. A solder bump composed of Sn-0.7% by mass Cu is formed on the electrode terminal of the second semiconductor chip as in the first semiconductor chip 1. The electrode terminals of the first semiconductor chip and the electrode terminals of the second semiconductor chip are arranged at corresponding predetermined positions so that they can be connected to each other. The number of terminals is approximately 2000, the height of the solder bumps is 20 μm, and the minimum distance between adjacent terminals is 60 μm. No flux is used.

[0053] For these semiconductor chips, a flip chip bonder equipped with an alignment mechanism, a heating mechanism, a pressing mechanism, and a tool height control mechanism is used to make the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com