Sorting machine for electronic component testing

A technology for electronic components and sorting machines, applied in sorting, measuring electricity, measuring devices, etc., can solve problems such as incorrect, unconsidered vibration, and electronic component damage test results, so as to prevent damage and improve reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Preferred embodiments according to the present invention will be described with reference to the accompanying drawings. Here, for the sake of brevity of description, descriptions on repeated or substantially identical configurations are omitted or compressed as much as possible.

[0045]

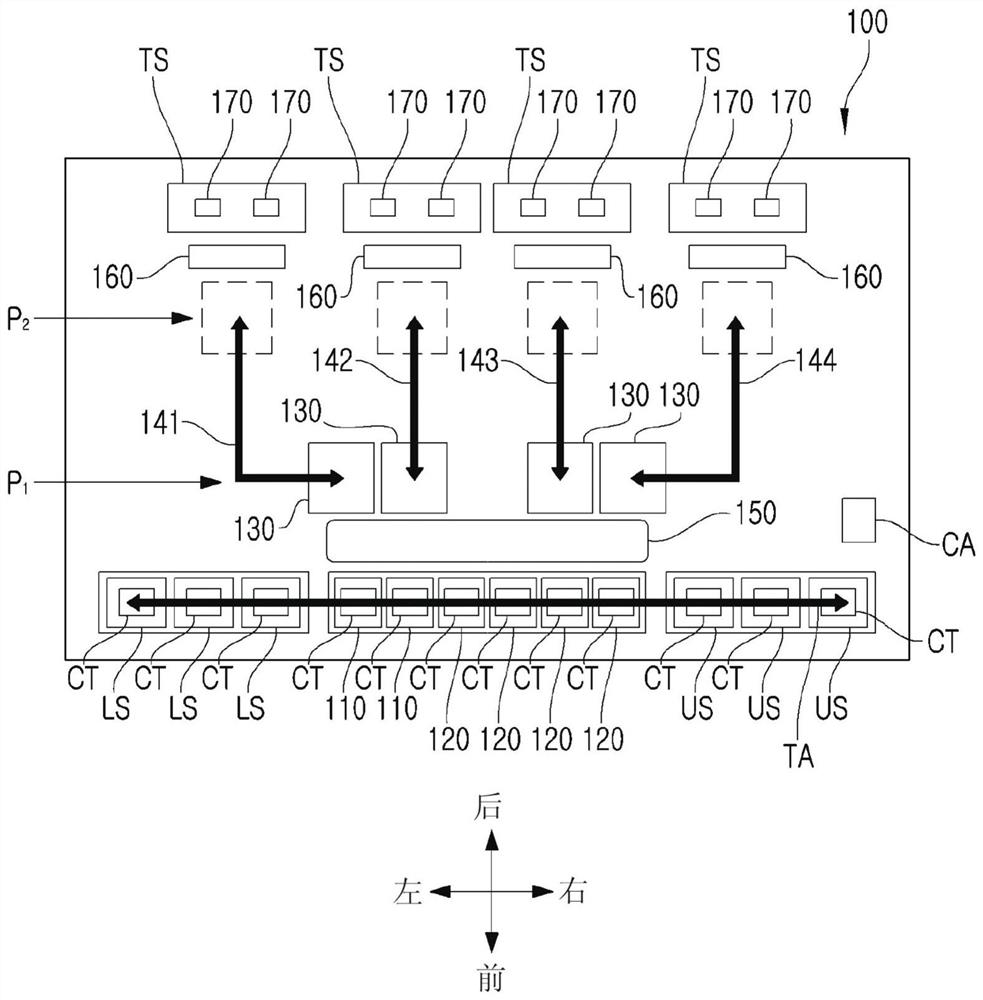

[0046] figure 1 It is a schematic plan view of a sorter (100, hereinafter abbreviated as 'sorter') for electronic component testing according to the most preferred embodiment of the application of the present invention.

[0047] like figure 1 As shown, the sorting machine according to the present invention includes: three loading stackers LS, two loading plates 110, four unloading plates 120, four loading platforms 130, four movers 141-144, the first pick-and-place 150, four second pickers 160, sixteen connectors 170, three unloading stackers US, conveyor TA and controller CA.

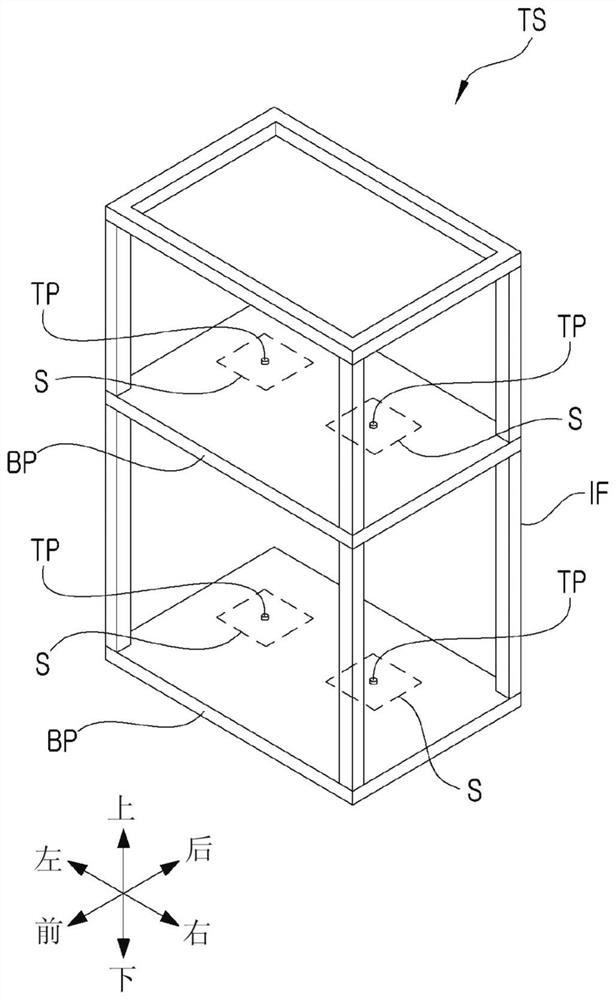

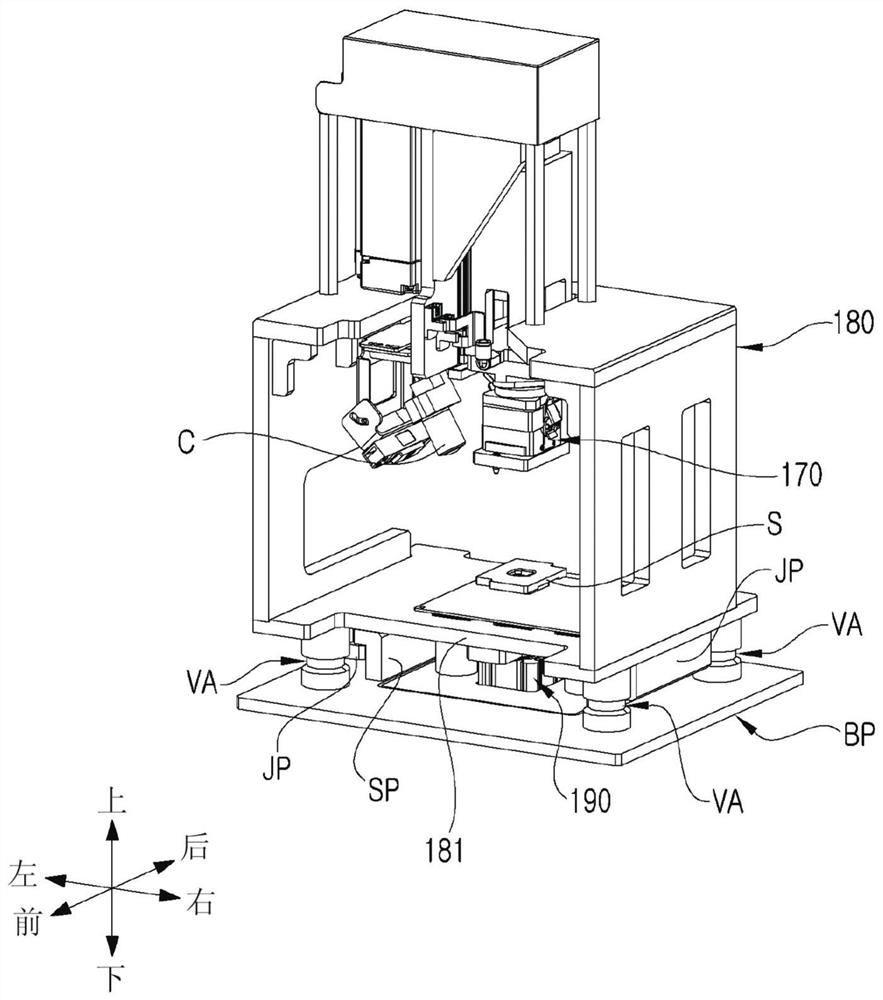

[0048] Before explaining the above configuration, first, the test station TS of the sorter will be exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com