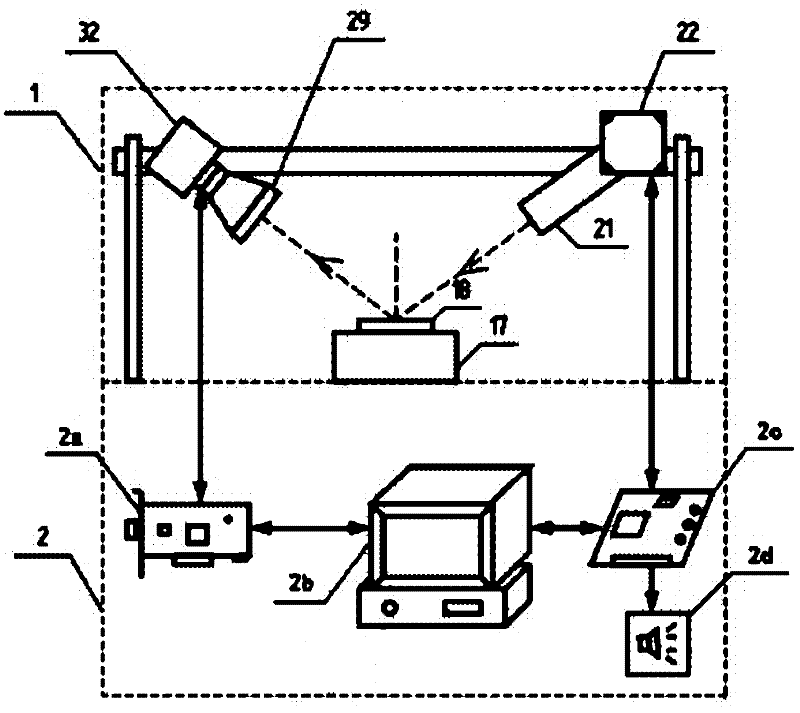

Device and method for detecting micro defects on bright and clean surface of metal part based on machine vision

A metal parts and machine vision technology, which is applied in the field of micro-defect detection devices for metal parts based on machine vision, can solve the problems of complex devices, inconspicuous features of coin micro-defects, affecting image processing effects, etc., and achieves the effect of easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

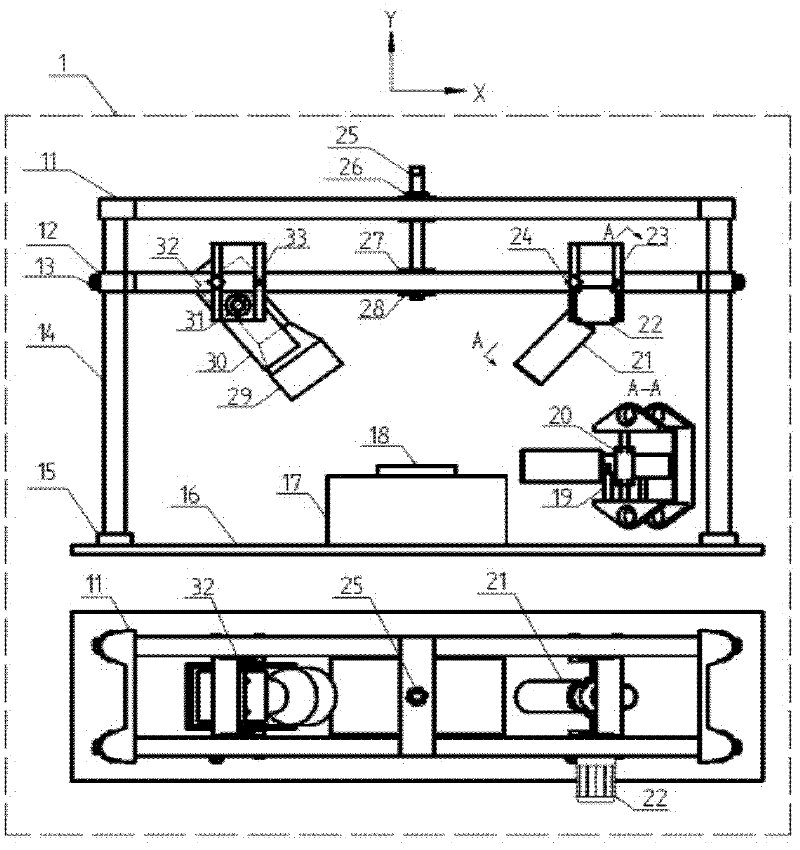

[0142] Embodiment: The detection object of this embodiment is a spectacle part of a certain specification, and the method for detecting micro-defects on the smooth surface of metal parts based on machine vision includes the following steps:

[0143] In the first step, a standard glasses part is placed on the inspection platform.

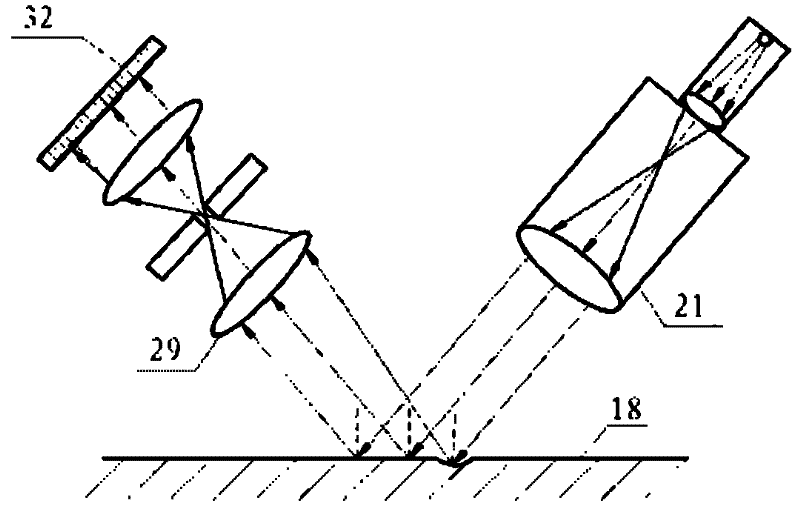

[0144] The second step, preliminary adjustment of imaging and coaxial illumination:

[0145] According to the position of the standard glasses parts, adjust the image of the CCD camera 32 and the parallel light source 21, turn the adjustment nut 27 to adjust the sliding bracket 12 to a suitable height along the Y axis, and tighten the bracket set screw 13. Then move the camera grooved sliding plate 33 to a suitable position along the X axis, and at the same time adjust the angle of the CCD camera 32 in the X-Y plane until the CCD camera 32 can clearly image, and tighten the sliding plate set screw 24 and the fastening knob 31. Then move the light s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com