Mercury vapor continuous monitoring device and monitoring method based on diode laser

A diode laser and monitoring device technology, which is used in measurement devices, material analysis by optical means, and testing of moving fluids/granular solids, etc., can solve the problems of complex system structure and poor real-time monitoring of mercury emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

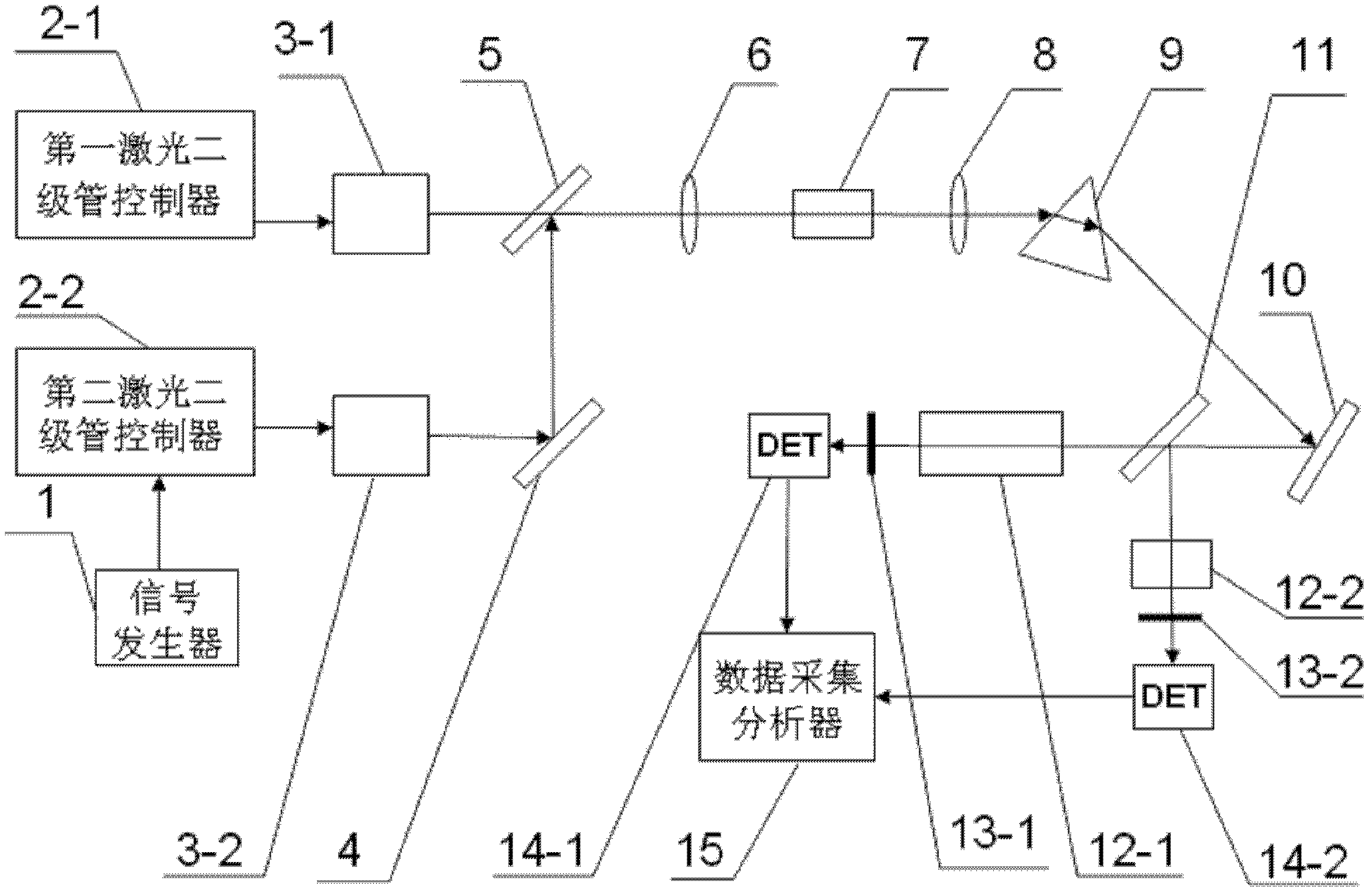

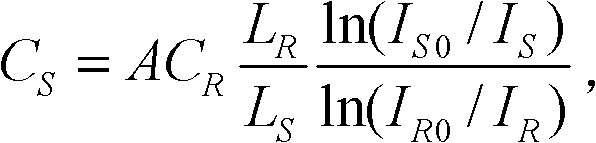

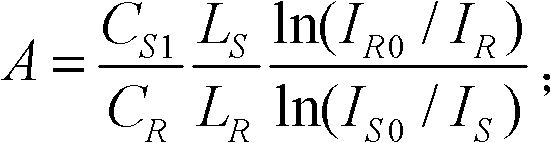

[0042] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the mercury gas continuous monitoring device based on diode laser described in this embodiment, it is made up of signal generator 1, the first laser diode controller 2-1, the second laser diode controller 2-2 , the first laser diode 3-1, the second laser diode 3-2, the first reflector 4, the dichroic mirror 5, the first convex lens 6, the BBO crystal 7, the second convex lens 8, the dichroic prism 9, the second reflection Mirror 10, beam splitter 11, sample cell 12-1, reference cell 12-2, first optical filter 13-1, second optical filter 13-2, first detector 14-1, second detector 14 -2 and a data acquisition analyzer 15,

[0043] The control signal output end of the first laser diode controller 2-1 is connected to the control signal input end of the first laser diode 3-1, and the laser beam emitted by the first laser diode 3-1 is incident on the front of the dichroic mirror 5 ...

specific Embodiment approach 2

[0052] Embodiment 2: This embodiment is a further description of Embodiment 1. The wavelength of the laser beam emitted by the first laser diode 3-1 is λ 1 and the laser beam wavelength λ emitted by the second laser diode 3-2 2 satisfy 1 / λ 1 +1 / λ 2 =1 / 254 relationship, the unit of the wavelength is nm;

[0053] The transmittance of the dichroic mirror 5 to the laser beam emitted by the first laser diode 3-1 is greater than 90%, and the reflectivity of the dichroic mirror 5 to the laser beam emitted by the second laser diode 3-2 is greater than 90%.

specific Embodiment approach 3

[0054] Specific embodiment three: this embodiment is a further description of embodiment one or two, the product of the concentration of mercury vapor in the reference cell 12-2 and the optical path length in the reference cell is 50 μg / m 2 ~500μg / m 2 .

[0055] The concentration of mercury vapor in the reference cell 12-2 can make the maximum absorption rate of light near the wavelength of 254nm reach 5%-50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com