Micro-voltage high-overload sensor chip of beam membrane single island structure

A sensor chip, high overload technology, applied in the direction of microstructure technology, microstructure devices, piezoelectric devices/electrostrictive devices, etc., can solve problems such as staying, not being able to adapt to the working environment in the aerospace field, and not being able to meet the precise measurement requirements in the aerospace field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

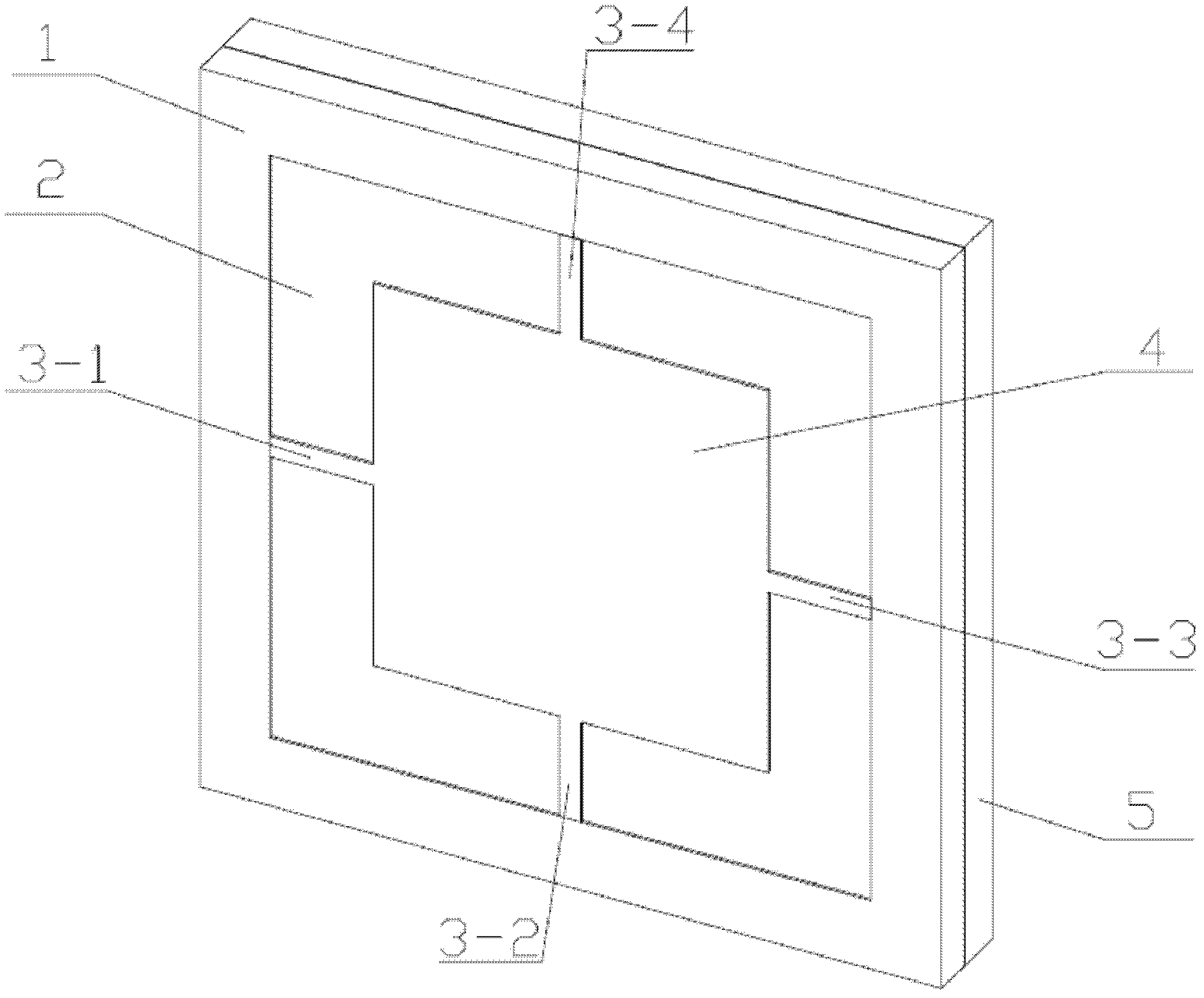

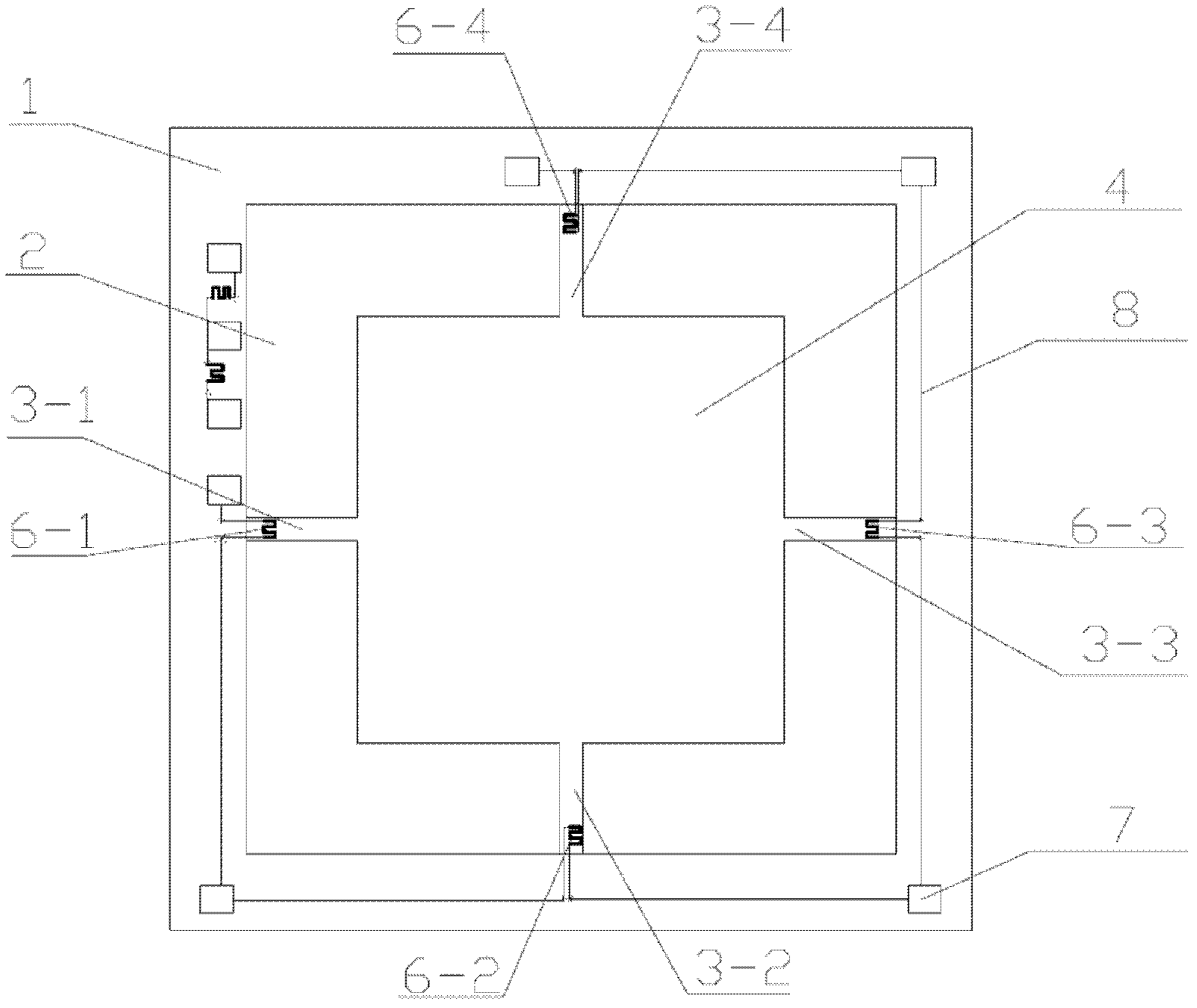

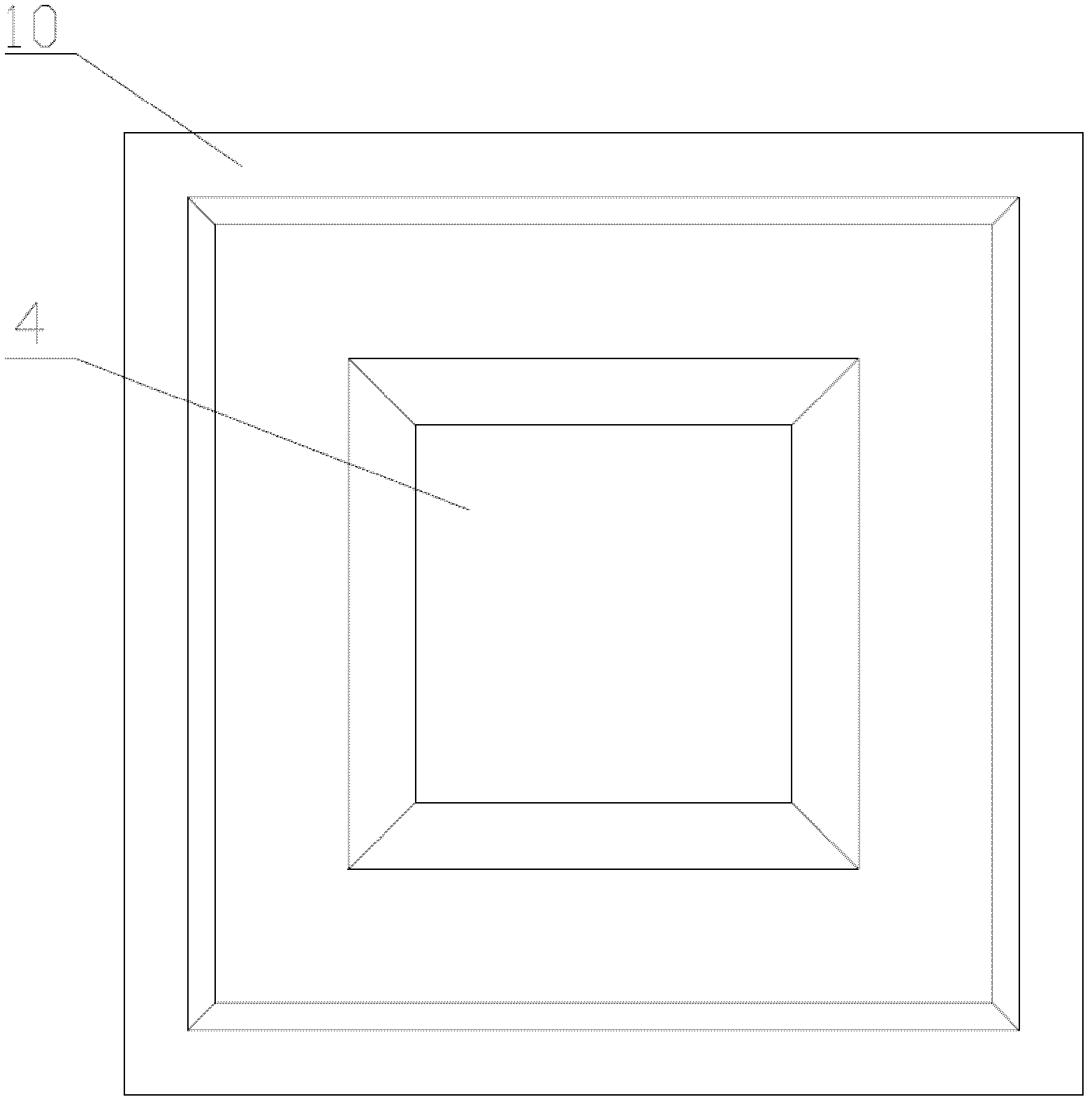

[0021] refer to figure 1 and figure 2 , a beam-membrane single-island structure micro-pressure high overload sensor chip, comprising a silicon substrate 1, and a mass block 4 and four single beams 3-1, 3-2, 3-3, 3-4 are processed in the middle of the silicon substrate 1 , the mass block 4 is connected to the silicon substrate 1 through four single beams 3-1, 3-2, 3-3, 3-4, and the silicon substrate 1, the mass block 4 and the four single beams 3-1, 3-2 are connected , 3-3, 3-4 are processed into a thin film 2 with a thickness of 10-30 μm, the back of the silicon substrate 1 is bonded with the Pyrex7740 glass 5, and the back of the mass 4 is thinned to make the mass 4 and Pyrex7740 glass 5 Leave a gap of 5-10μm in the vacuum environment, refer to image 3 and Figure 4 , insert the anti-adsorption electrode 9 on the Pyrex7740 glass 5 into the bonding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com