Device for rapidly treating ring formation of rotary kiln and method

A processing device and rotary kiln technology, applied in the fields of metallurgy, chemical industry, building materials, refractory rotary kiln, can solve the problems of lack of control device, inconvenient operation, small impact force, etc., achieve direct energy transfer, improve ring cleaning efficiency, The effect of high impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

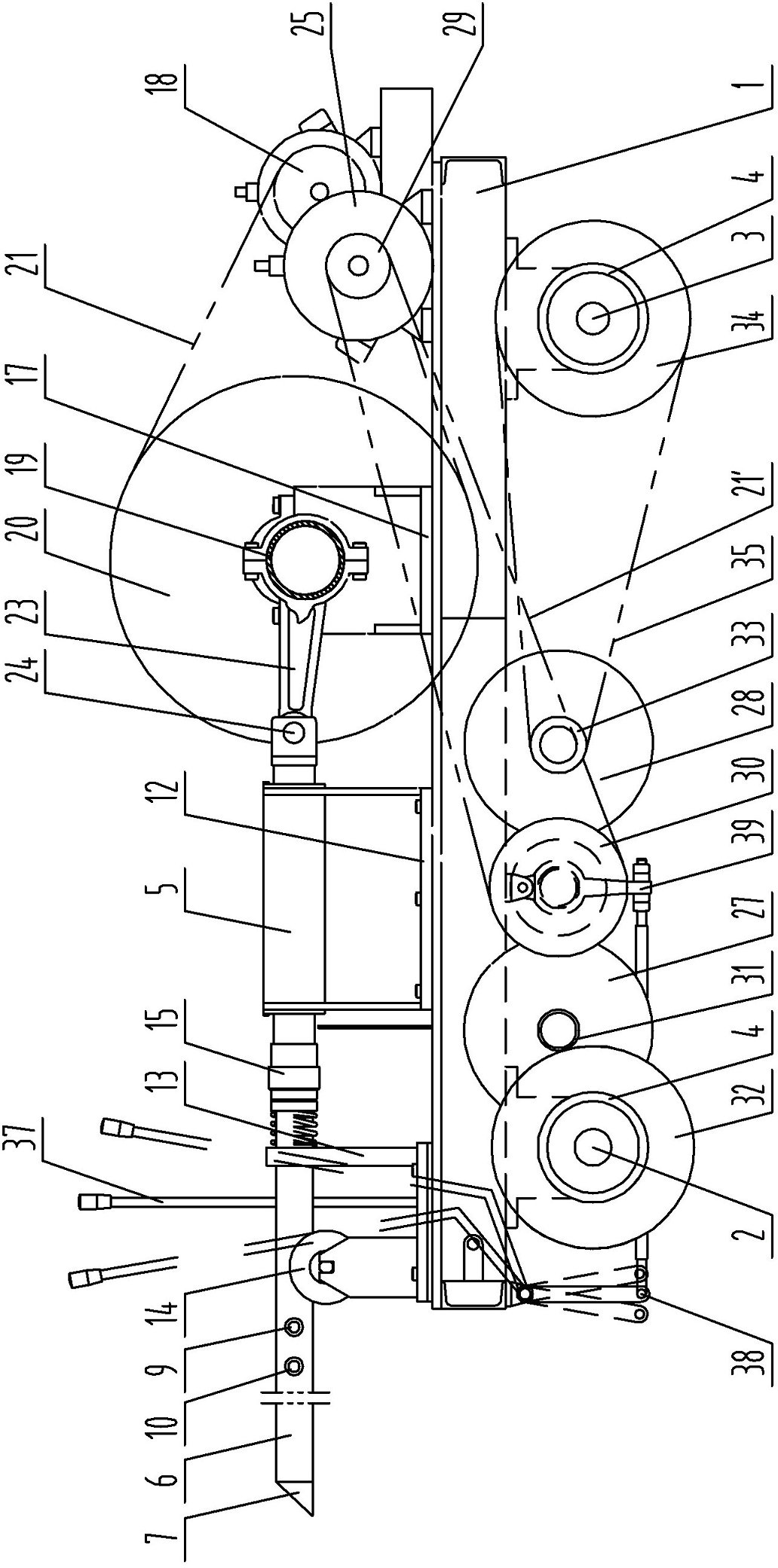

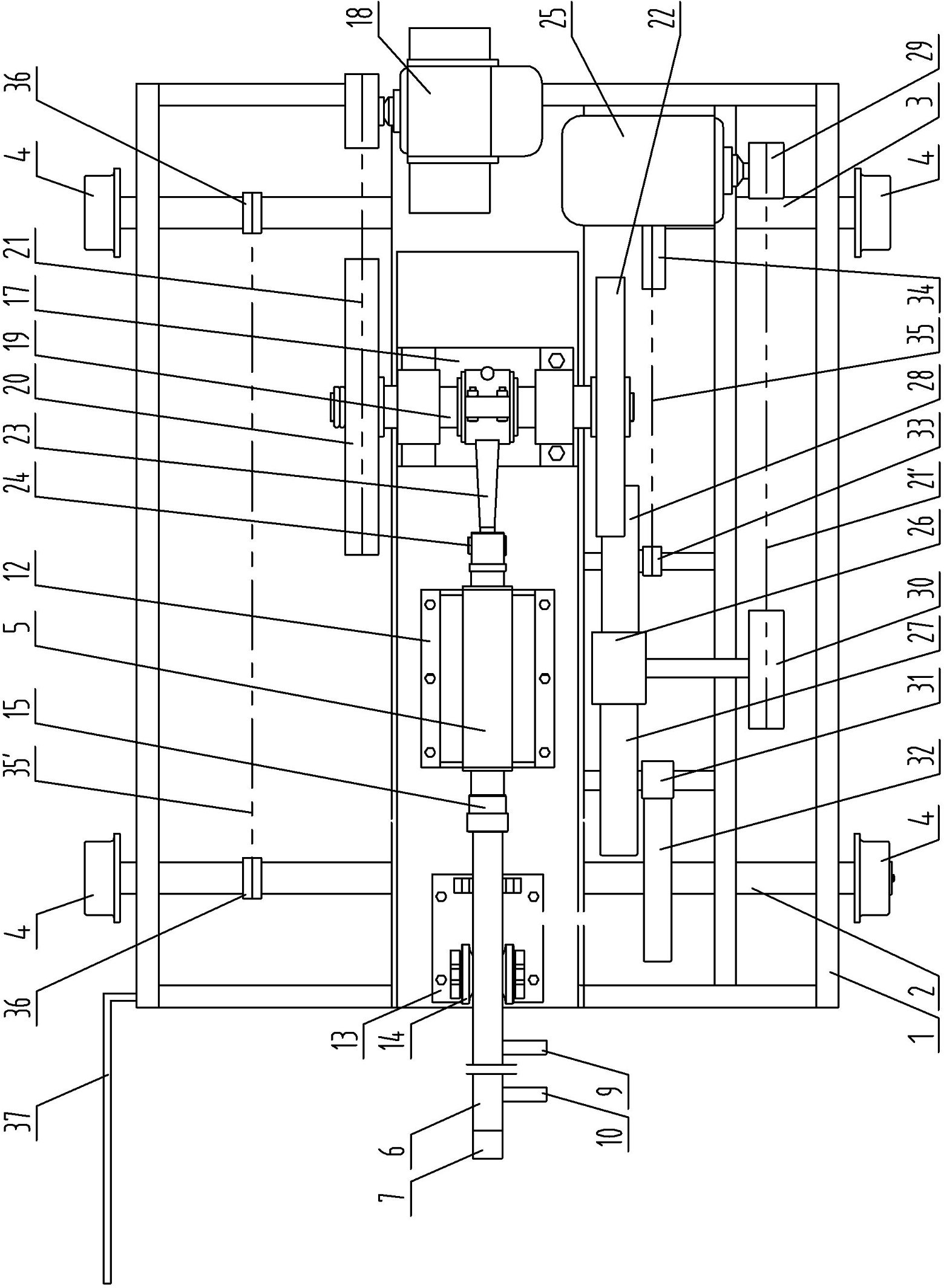

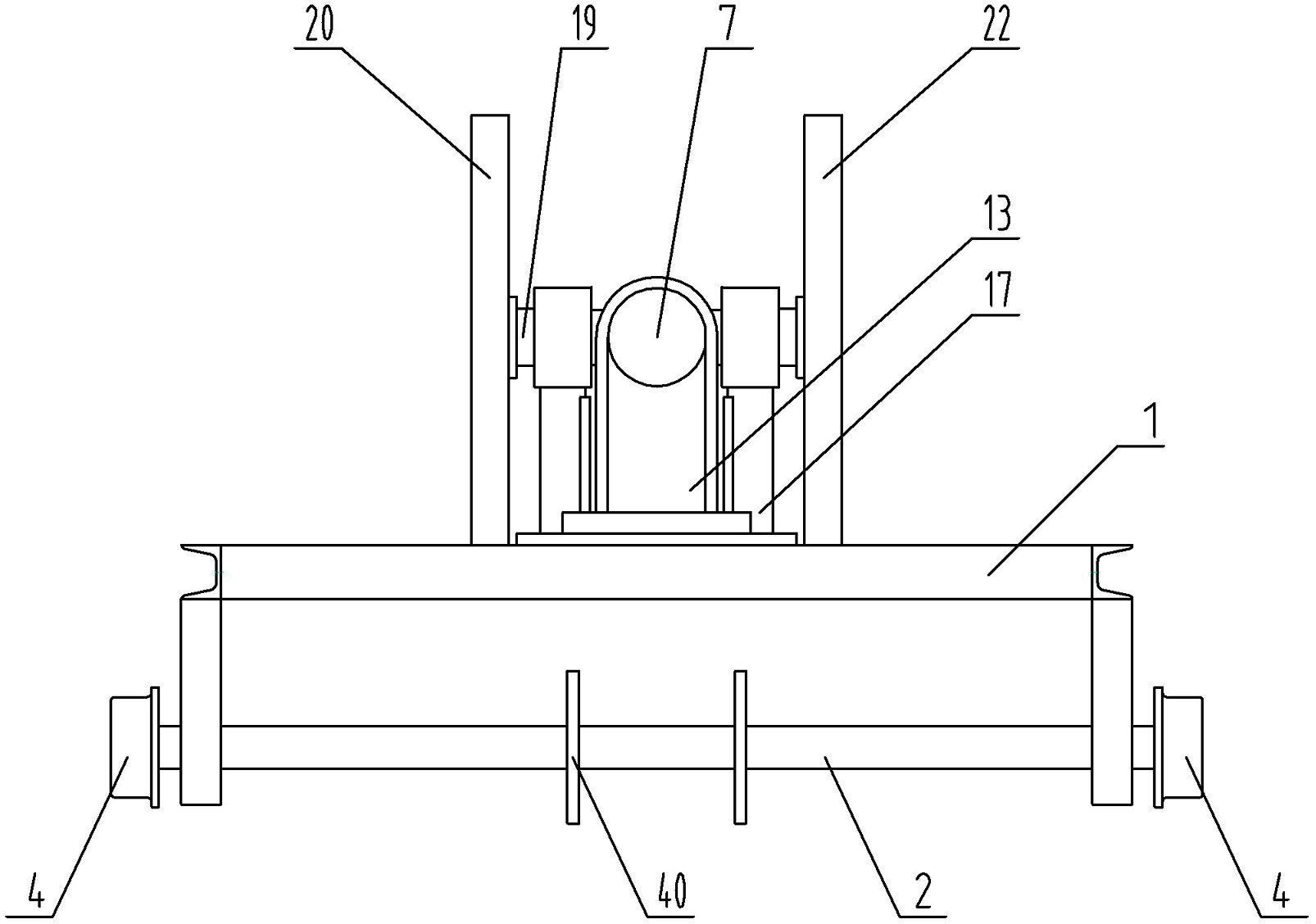

[0032] see Figure 1 to Figure 5 , Figure 7 , in the figure, the rotary kiln ring fast processing device of the present invention comprises a kiln car, an impact bar 5 arranged on the kiln car, an impact bar support device below the impact bar 5 and an impact bar driving device connected to the impact bar 5 tail. The kiln car includes a vehicle frame 1, a front axle 2 and a rear axle 3, and wheels 4 installed on both sides of the front axle 2 and the rear axle 3. The front end of the impact rod 5 is movably connected with a hollow shovel 6, and through the shovel The support device is fixed on the kiln car, the front end of the shovel bar 6 is fixed with the shovel head 7, and the interior of the shovel bar 6 is fixed with a cooling water pipe 8, and the water inlet 9 of the cooling water pipe 8 is fixed at the rear end of the shovel bar 6, and the rear end of the shovel bar 6 is separately A water outlet pipe 10 is fixedly installed, and the water outlet pipe 10 communicate...

Embodiment 2

[0038] see Figure 6 , the meanings represented by the same numbers in this embodiment are the same as in Embodiment 1, and will not be repeated here. The difference is that the cooling water pipe 8 in this embodiment is fixed on the inner wall of the shovel rod 6 through two four-sided support rods 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com