Two-way multifunctional electromagnetic valve

A solenoid valve and multi-functional technology, applied in the field of solenoid valves, can solve problems such as high pull-in voltage, slow response, and system failure, and meet the requirements of small dynamic pressure changes, lower technical level, and shorten electromagnetic response time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

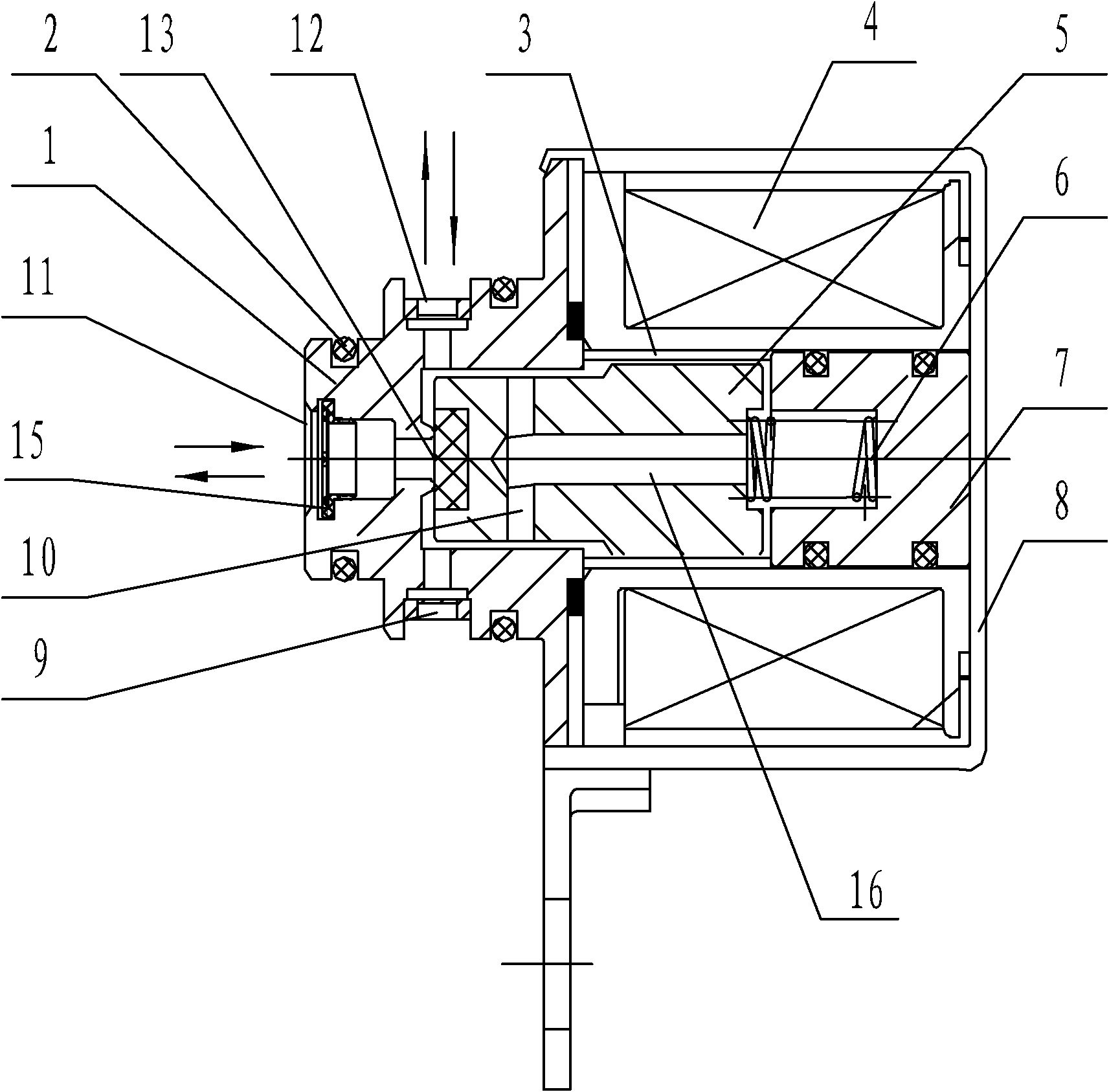

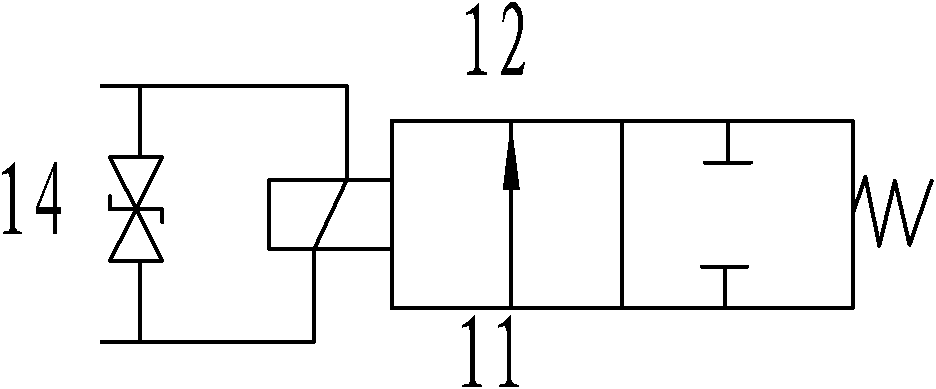

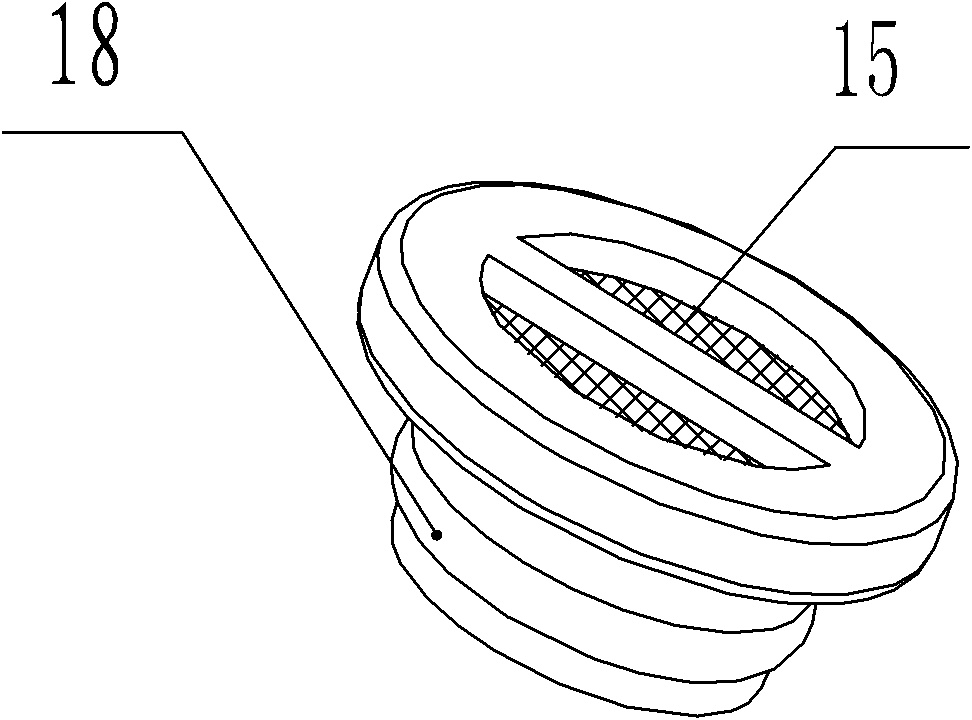

[0025] like figure 1 , figure 2 As shown, the present invention mainly includes a valve body 1 and an electromagnet part. The valve body 1 is provided with a medium inlet 11 and a medium outlet 12, which can be communicated with the gas / liquid source and the gas / liquid device respectively. The electromagnet part The valve core mainly includes coil 4, static magnetic core 7, and moving magnetic core 5. The coil injection molding assembly is adopted. The valve core is arranged in the coil assembly. TVS tube 14, lead wire and coil are also arranged in the coil injection molding assembly. 4 and the skeleton, the TVS tube 14 is connected in parallel with the coil 4, the lead head is connected and led out from the coil 4, and is fully encapsulated in the coil injection assembly. The setting of the TVS tube can effectively suppress the high voltage at the moment of rapid power failure, reduce the volume of the coil and related parts, shorten the electromagnetic response time, and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com