Carbon oxide huff-n-puff, water control and oil increment method for horizontal well

A carbon dioxide, horizontal well technology, applied in the direction of earthwork drilling, wellbore/well components, production fluid, etc., can solve the problems of difficult operation, inability to achieve economical efficiency, high technical requirements, and achieve the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0064] 1. Well selection: an abnormal water-flooded well in a high-porosity and high-permeability conventional heavy oil reservoir with side-bottom water. For the structural location, see figure 2 . Porosity 30.75%, permeability 905.3md, reservoir depth 1730m; reservoir pressure 15.4MPa, formation pressure coefficient 0.89; reservoir temperature 63℃; crude oil viscosity 475mPa.s; crude oil density 0.94g / cm 3. The formation water salinity is 1037. Due to the communication between the well fluid and the bottom water during the production process, the water content is high immediately after production, which is an abnormally high water content. Production status image 3 . The thickness of the oil layer is 6m, and the production section of a single well is 44m / 1 section. The well trajectory is shown in Figure 4 . The controlled geological reserves are 2.5wt, the recoverable reserves are 0.5wt, the remaining recoverable reserves are 0.5wt, and the remaining oil saturation ...

example 2

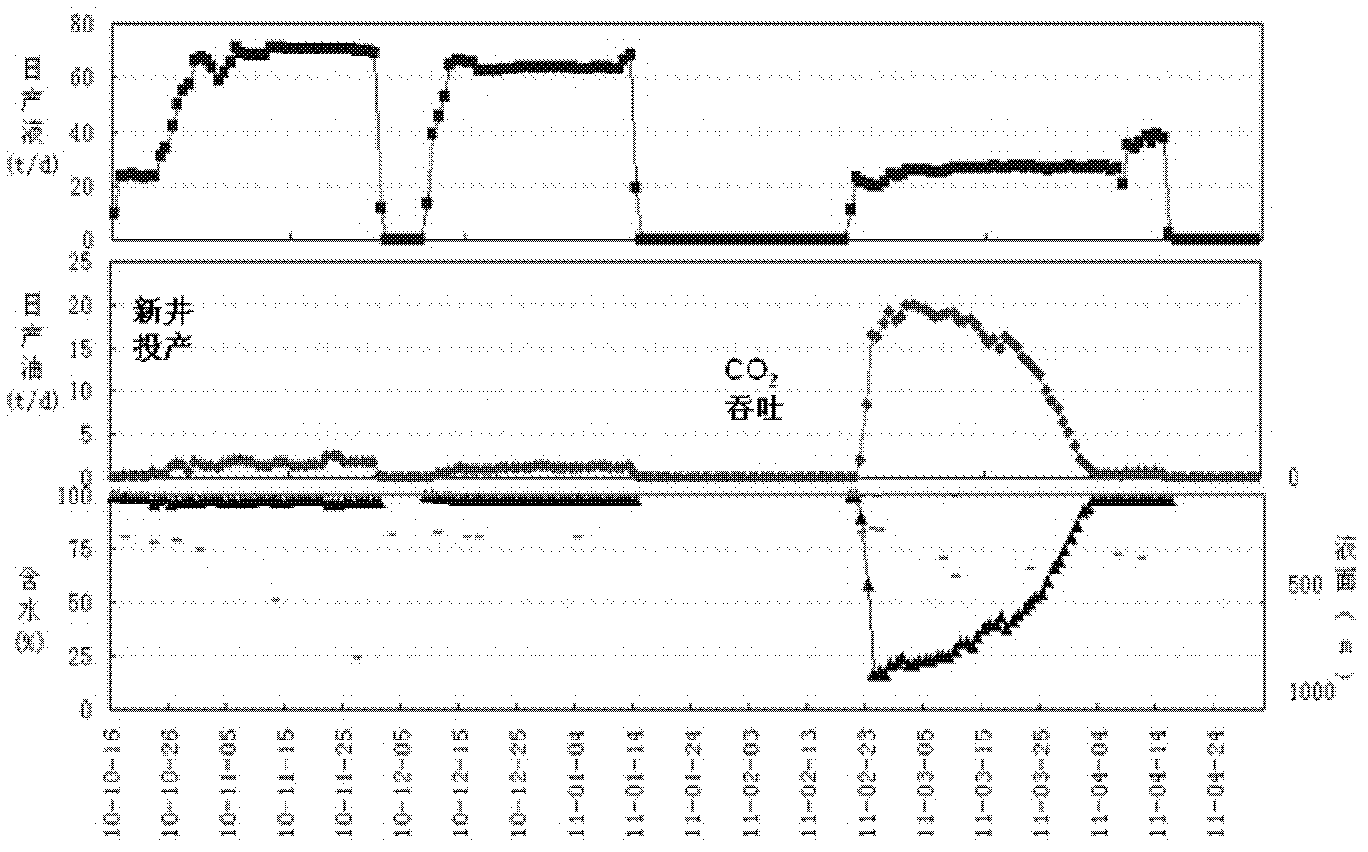

[0107] 1. Well selection: a horizontal well in a conventional heavy oil reservoir with edge and bottom water, located at a higher part of the fault root, see Figure 7 . The production well section is 173.7m / 2 sections; the thickness of the oil layer is 6m, see Figure 8 . Reservoir depth: 1530m; reservoir pressure: 14.8MPa; porosity 29.09%, permeability 148.8md; reservoir temperature: 60°C; crude oil viscosity: 116mPa·s (underground) / 240mPa·s (ground 50°C), Crude oil density: 0.9410g / cm 3 ; The geological reserves of the small layer are 7wt, the recovery degree is only 4.0%, and the calibrated water flooding recovery rate is 10.0%. The water cut rises rapidly in the early stage of production, and the water cut reaches 100% when the recovery rate is only 4%. The analysis shows that the initial liquid volume is high, and the high liquid production intensity causes local bottom water coning, see Figure 9 . Compliant with CO 2 Huff and puff control water increase oil well ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com