High-strength steel bar enhanced engineered cementitious composites (ECC)-hollow steel pipe ultra high performance concrete (UHPC) combination column member and manufacturing method thereof

A technology of high-strength steel bars and hollow steel pipes, applied in the field of heavy-duty, high-rise, and long-span pier column components, can solve problems such as steel pipe corrosion, column rigidity reduction, increased construction costs and construction difficulties, and achieve increased compression stability and improved Bending rigidity, good effect of high temperature curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the drawings.

[0034] As shown in the figure, the production process of the component is as follows:

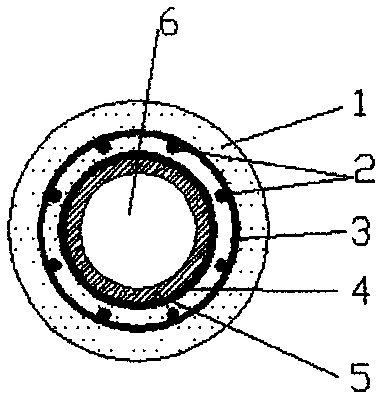

[0035] First select and make the steel pipe 1, and then use the centrifugal forming process to pour the UHPC material 5 on the inner surface of the steel pipe 1. After forming, pour out the excess slurry in the steel pipe 1, and steam at 90℃ and 90% relative humidity. After curing for 48 hours, store it for later use; during engineering construction, install the prefabricated hollow steel pipe UHPC in place according to the construction drawings, and then tie the steel bars around its periphery according to the drawings, and assemble the outer formwork, pour ECC material 1, and remove it after curing for the specified time External template.

[0036] It should be noted that the prefabricated hollow steel pipe UHPC can be used as a load-bearing member for the construction of the superstructure after be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com