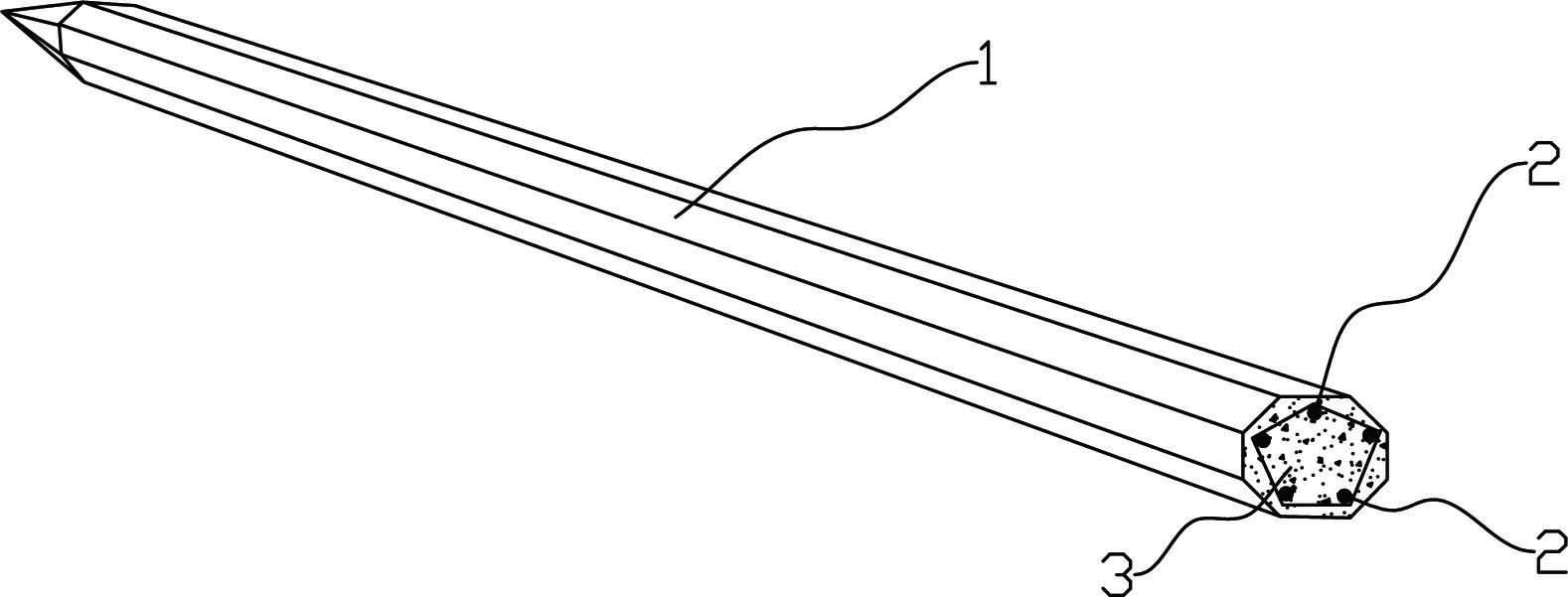

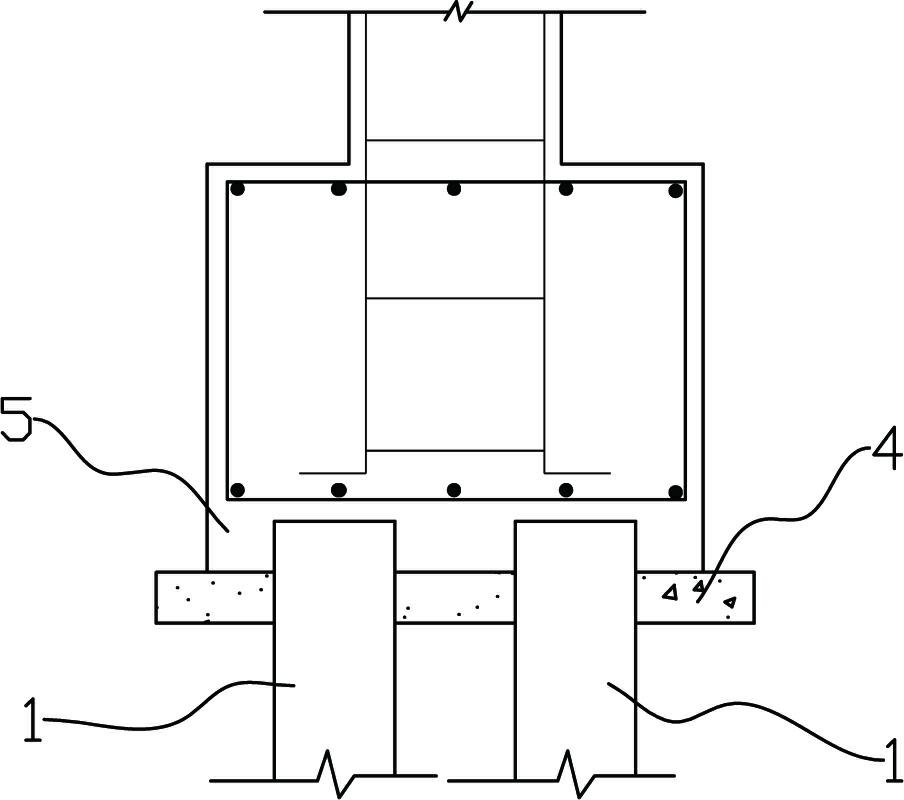

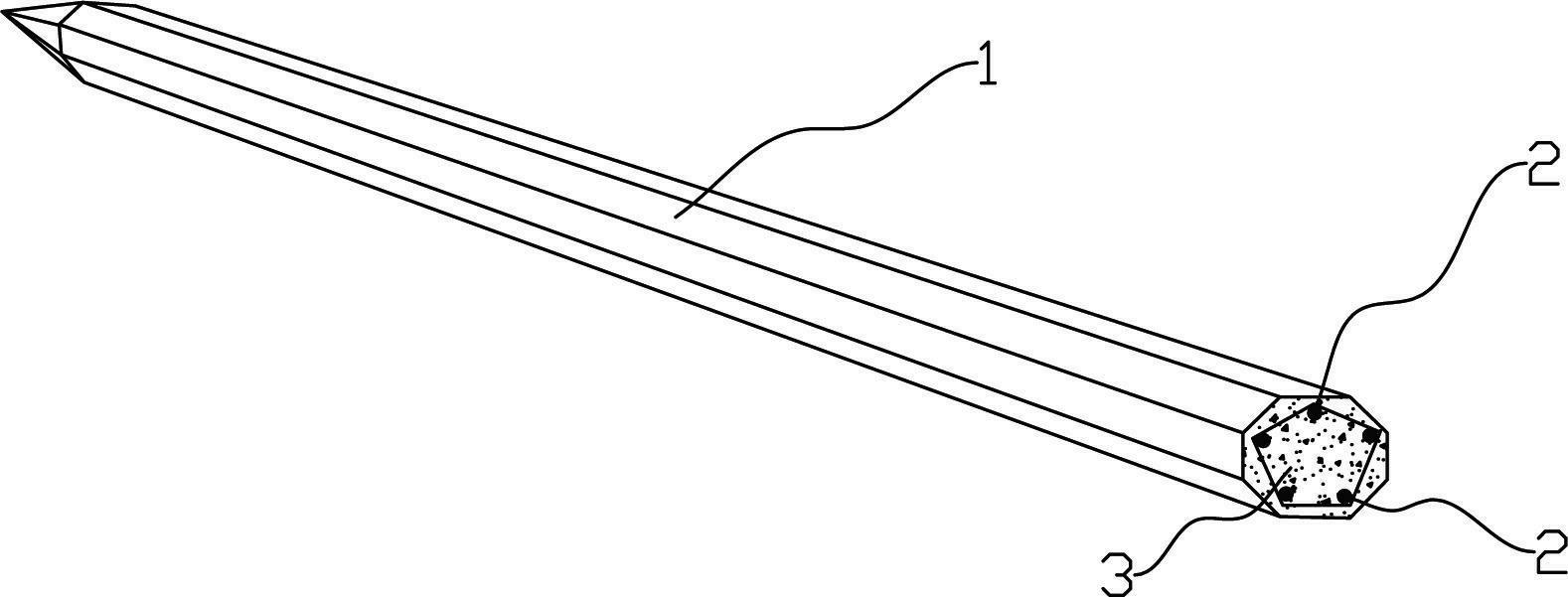

Octagonal pile and foundation structure applying octagonal pile

A technology of octagonal piles and foundations, which is applied to foundation structure engineering, sheet pile walls, buildings, etc., can solve problems such as poor reliability and durability, increased construction costs, and waste of land, so as to achieve flexible and fast construction, reduce construction costs, and save space. less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Located in a substation in Yunfu City, the substation has a 292-meter-long 180mm-thick wall and 59 equipment. The weight of the equipment ranges from 0.7 tons to 1.0 tons; the 180 mm thick brick wall is used as foundation beams, and there are 60 pillars every 5 meters. Since the surface ranges from 1 to 3 meters as backfill, it is not feasible to directly build a natural foundation, and foundation treatment is required. Moreover, one side of the power station is adjacent to a fish pond, and pile drivers cannot enter. In this case, we thought of octagonal piles with lower requirements on the construction site and more flexible construction methods.

[0026] At the same time, we also compared the economic advantages and disadvantages of the two foundation treatment methods:

[0027] ① 250x250 prefabricated concrete square piles: only considered as friction piles, only one is needed under each wall column, but considering the requirements of bending moment, two are requi...

Embodiment 2

[0031] A temporary mixing plant located in Desheng area of Shunde requires foundation treatment. The geological condition of this area is poor and the surface layer is covered with thick soft soil. In the feasibility study stage, we make the following assessments:

[0032] If powder-spraying piles are to be processed, 100 piles are needed per square meter, and each pile is 6 meters long. Considering the cost of powder-spraying piles at 50 yuan per meter, an investment of 30,000 yuan is required; There are 4 piles per square meter, and the length of the piles is also 6 meters. Considering the cost of 55 yuan per pile, an investment of 22,000 yuan is required. It can be seen that under the condition of equal utility, choosing octagonal piles is relatively economical in investment and reliable. In the piling process, the effect of foundation treatment can be known immediately, and the number and length of piles can be increased or reduced on site, and there is no need to do in...

Embodiment 3

[0034] It is located in a small electric house in Shunde, which needs foundation treatment. Let’s compare two feasible solutions:

[0035] If the natural foundation is used to push down the wooden piles, 60 5-meter-long φ120 pine piles are required, calculated at 70 yuan per 5-meter wooden pile, and 4,200 yuan is required to purchase piles; if octagonal piles are used instead, each 5-meter-long octagonal pile is required Calculated at 50 yuan, it takes 3,000 yuan to buy piles. It can be seen that the investment in piles alone has saved 29%. Moreover, termites in this area have serious erosion of wooden piles, and the phenomenon of wooden piles being corroded by other factors cannot be ignored. In contrast, the quality of the pile body of octagonal piles is much more stable and stronger than wooden piles, and it saves The use of wood is also the green environmental protection advocated today.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com