Supersonic flame spraying iron aluminum and zinc composite board production line

A supersonic flame, production line technology, applied in the direction of coating, layered products, melt spraying, etc., can solve the problems of high pollution, high cost, shortage, etc., to achieve convenient manufacturing, good adhesion, smooth board surface. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

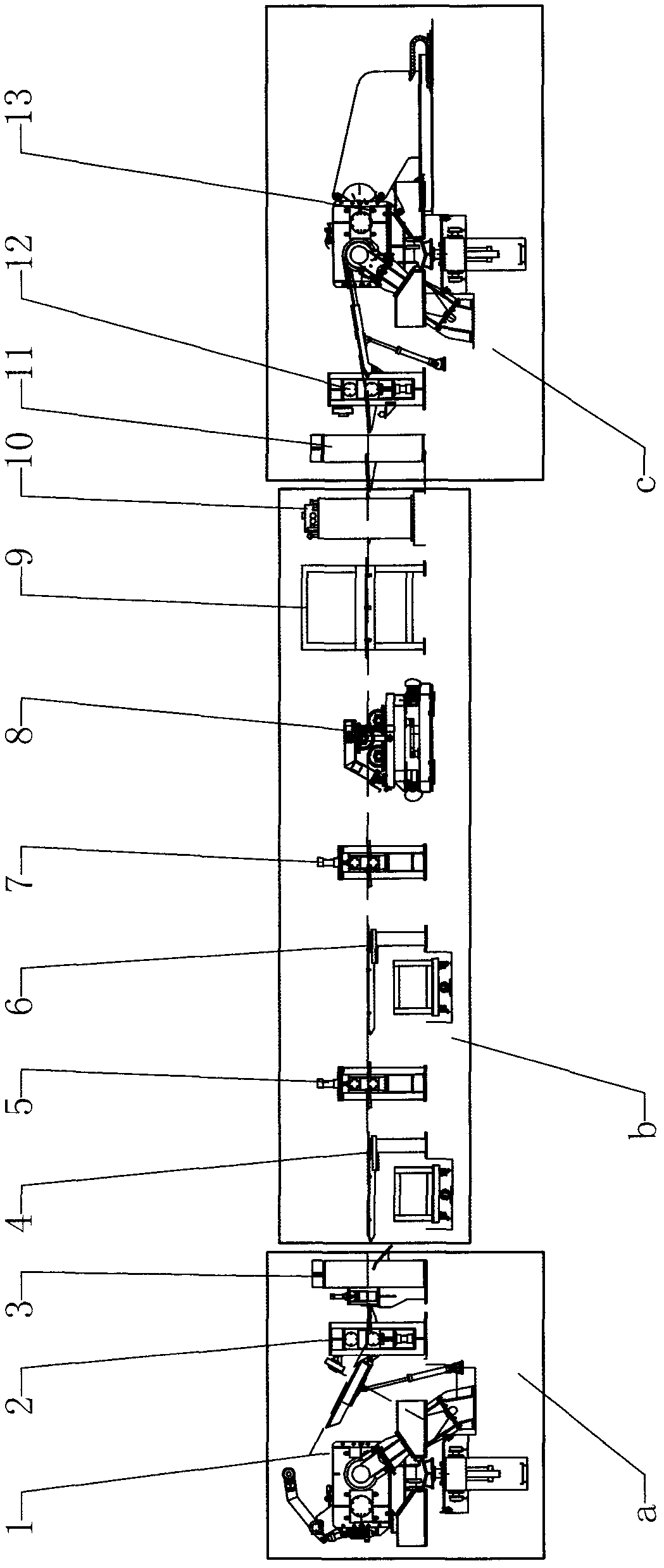

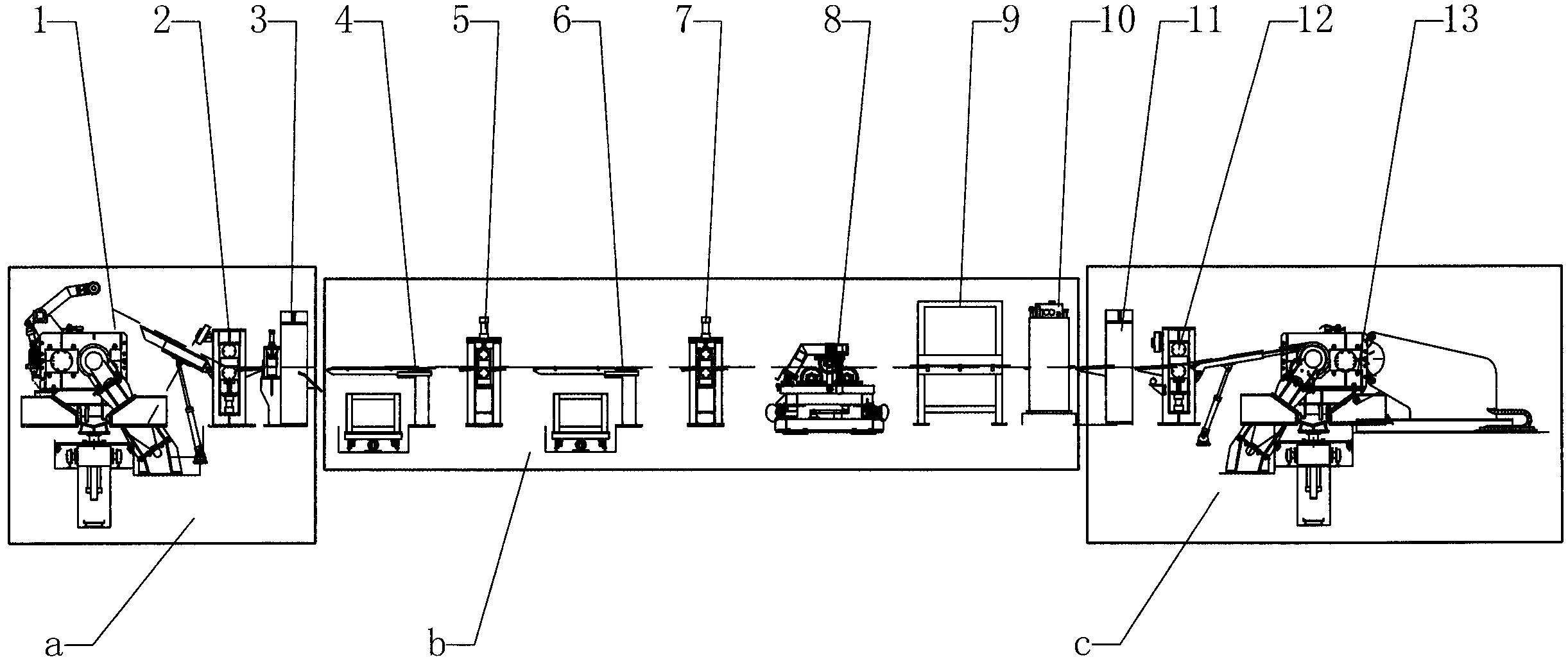

[0011] The specific implementation of the production line for supersonic flame spraying iron-aluminum-zinc composite panels of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] The invention relates to a multi-layer metal composite board, which uses an iron board as a substrate, zinc as a face plate, and aluminum as a core board to form an iron-aluminum-zinc composite board, that is, an iron-aluminum-zinc three-layer composite board.

[0013] When compounding aluminum and zinc powder on the iron plate, use a supersonic flame spraying machine (4, 6), that is, sprinkle aluminum and zinc powder on the iron plate in sequence, and use supersonic flame to compound aluminum and zinc powder on the iron plate, The aluminum and zinc powders are combined with the iron plate in turn to form the aluminum and zinc layers of the clad plate, which is then cold-rolled and leveled.

[0014] Such as figure 1 As shown, a supersonic fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com