Numerical control solvent oil recovering and refining instrument

A solvent oil and oil technology, which is applied in the petroleum industry, hydrocarbon oil distillation control/regulation, hydrocarbon distillation, etc., can solve the problems of lack of micro (small) recovery equipment and difficult recovery of waste solvent oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

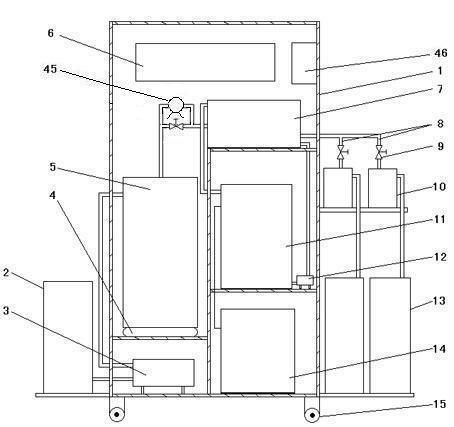

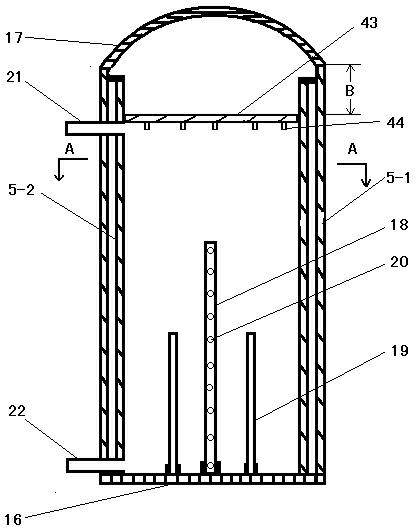

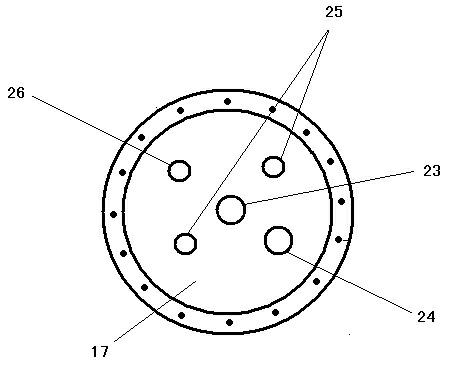

[0027] refer to figure 1 — Figure 8, a kind of numerical control solvent oil recovering and refining instrument, comprises the working system in the body 1 and the electronic control system 6 that cooperates thereof, is provided with the roller 15 that is convenient to move under the body; , Vacuum negative pressure pump 45, condensate liquefier 7, product oil output oil classification treatment device, harmful gas explosion-proof and monitoring and alarm system 46. Among them, the raw material oil liquid device includes a raw material oil liquid metering tank 2 and an oil inlet pump 3; the distillation vessel 5 is a double-layer vacuum insulation stainless steel structure (including an outer cylinder 5-1 and an inner cylinder 5-2), and its bottom plate 16 is made of 430 stainless steel. A heat pipe 18 and four heat-extending heat conduction rods 19 are arranged on the top, and a plurality of heat conduction holes 20 are distributed on the heat pipe 18; a liquid inlet 21 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com