Automatic preparation and supply system and method for emulsion

A technology of emulsion and emulsion pumping station, which is applied in the direction of chemical instruments and methods, earthwork drilling, mixer accessories, etc., can solve the problems of hydraulic system not working normally, low precision of emulsion, soaping reaction, etc., and achieve strong promotion Application value, elimination of low precision, and effect of reducing liquid return resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings.

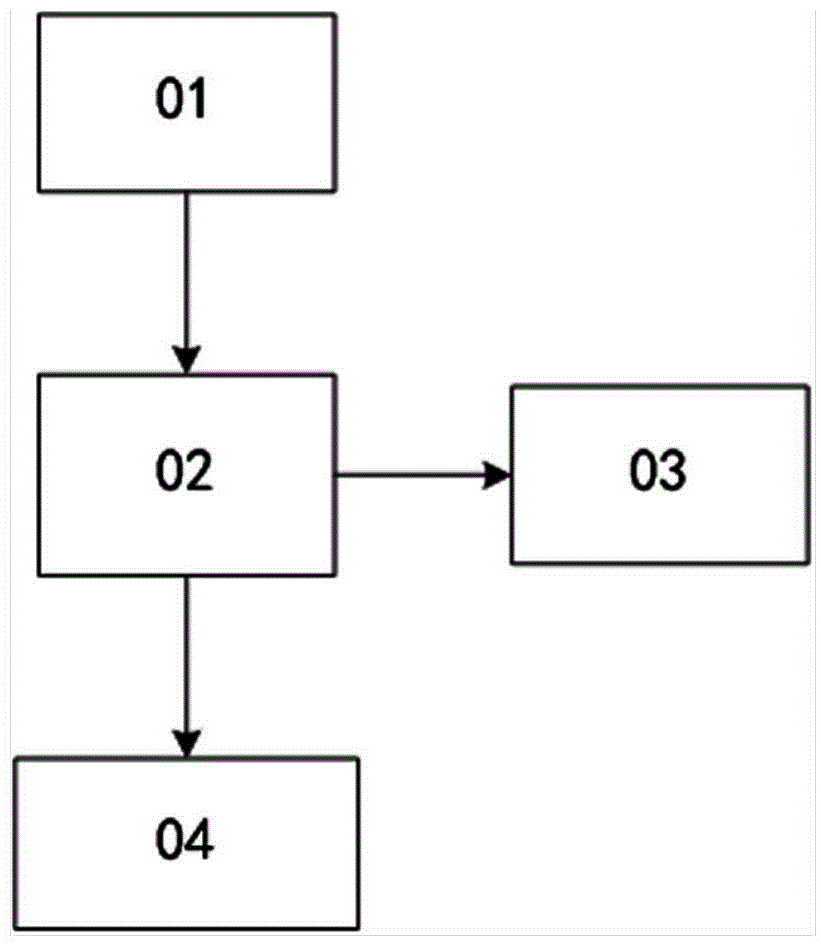

[0038] figure 1 It is a structural schematic diagram of an embodiment of an emulsion automatic dispensing system disclosed in the present invention, as figure 1 As shown, an automatic emulsion distribution system disclosed in the present invention includes: a ground centralized liquid distribution system 01, a horizontal buffer water tank 02, and an emulsion pump station 03 in the mining area. The ground centralized liquid distribution system 01 and the horizontal buffer water tank 02 pass through Pipelines plated with stainless steel, zinc or nickel are connected. The horizontal buffer tank 02 and the emulsion pump station 03 in the production area are also connected through sub-pipelines plated with stainless steel, zinc or nickel. According to the actual demand for the emulsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com