CNC machine tool processing system based on cloud platform

A technology of CNC machine tools and processing systems, which is applied in general control systems, control/adjustment systems, program control, etc., can solve the problems of inability to realize remote monitoring of CNC machine tool processing, cloud control of CNC machine tool processing, etc., to achieve convenient learning, Realize cloud processing and realize the effect of cloud manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

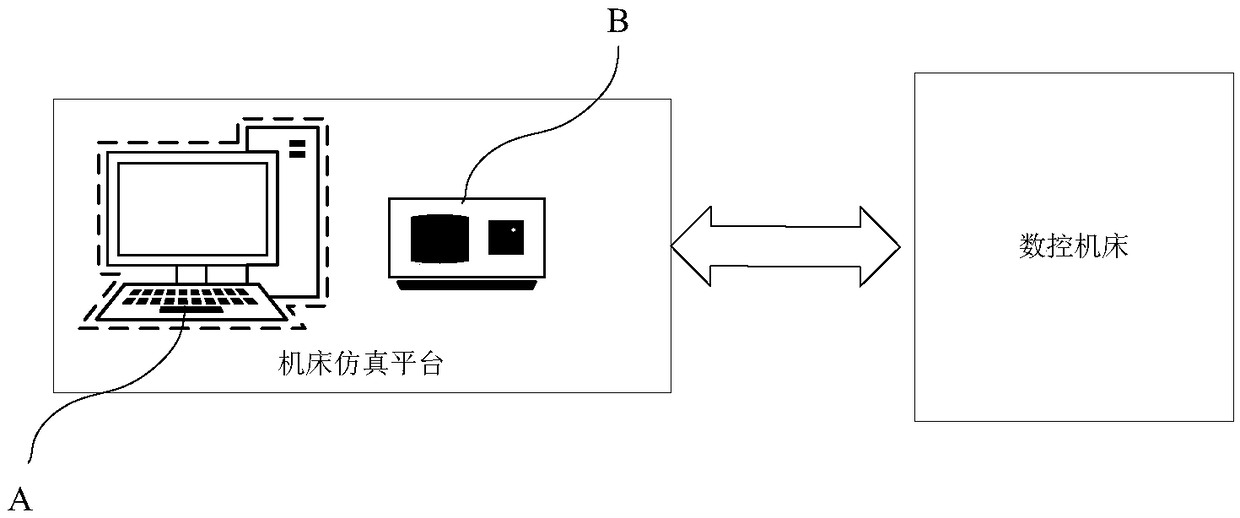

[0041] Embodiment 1: as figure 1 As shown, a kind of CNC machine tool processing system includes: CNC machine tool; a machine tool simulation platform that is connected with the data of the CNC machine tool and can carry out data communication with the CNC machine tool; the machine tool simulation platform can simulate the workpiece processing program, and The workpiece processing program is sent to the CNC machine tool, and the CNC machine tool processes the workpiece. At the same time, various state information and parameters during the CNC machine tool processing process can be displayed through the machine tool simulation platform; or the machine tool simulation platform sends the workpiece processing program to the CNC machine tool, and the CNC machine tool The workpiece is processed, and various state information and parameters in the process of CNC machine tool processing can be displayed through the machine tool simulation platform. The machine tool simulation platform...

Embodiment 2

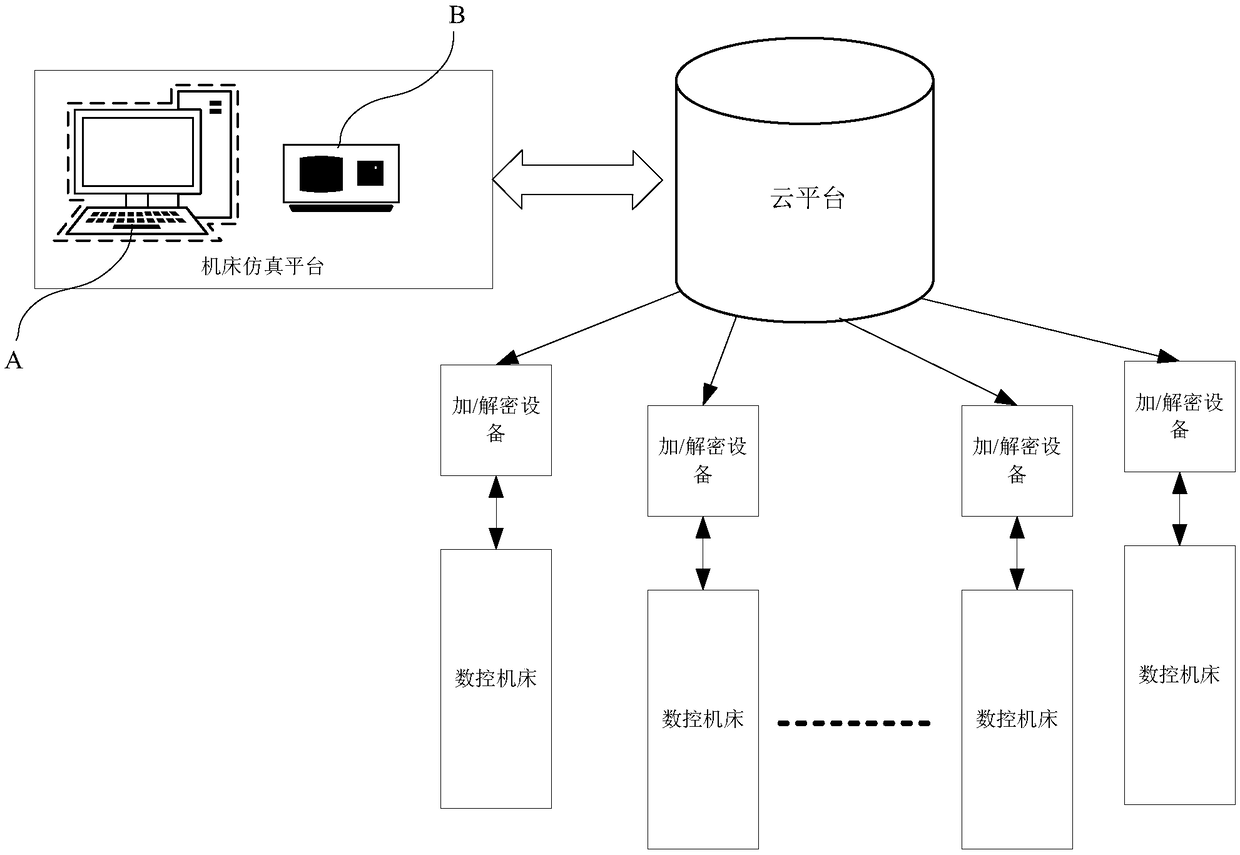

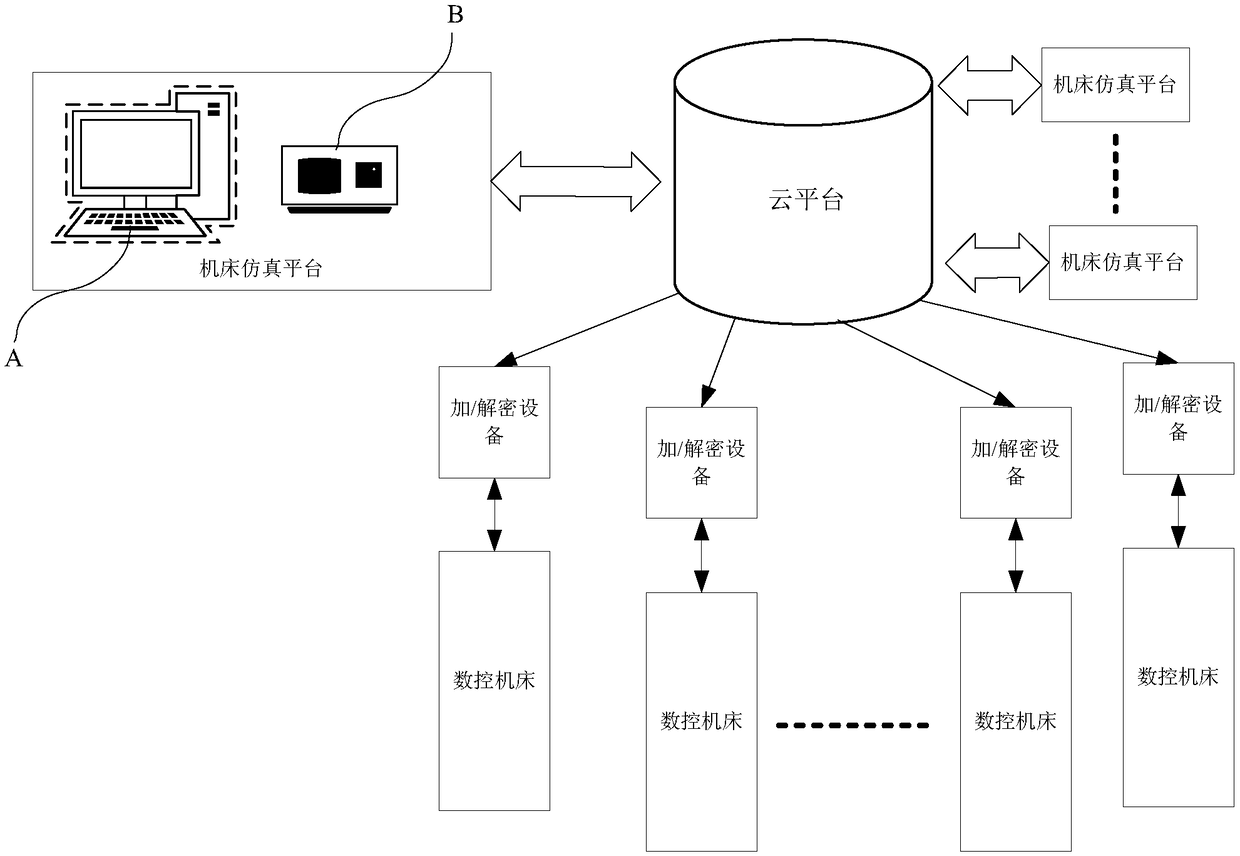

[0044] Embodiment 2: as figure 2 and image 3 As shown, a CNC machine tool processing system based on a cloud platform includes: a CNC machine tool; it can simulate the workpiece processing program, and send the workpiece processing program that has been successfully verified by simulation to the cloud platform, and the verified processing program can be updated. Stable and safer; or directly send the workpiece processing program to the cloud platform (some processing programs are verified, there is no need to re-verify again to ensure efficiency), and at the same time, various state information during the CNC machine tool processing process A machine tool simulation platform for displaying parameters; it is respectively connected with the machine tool simulation platform and the CNC machine tool data, used to receive the workpiece processing program sent by the machine tool simulation platform, and send various status information and parameters during the CNC machine tool pr...

Embodiment 3

[0047] Embodiment 3: The other parts of the system are the same as Embodiment 2, and will not be repeated here, only the differences will be described. like Figure 5 As shown, when the cloud platform sends the workpiece processing program to the CNC machine tool, it will judge whether the CNC machine tool can work normally. The specific process is as follows:

[0048] After the cloud platform receives the workpiece processing program and tasks sent by the machine tool simulation platform, it sends the workpiece processing program to the CNC machine tool A selected by the cloud platform for verification and processing. The cloud platform monitors and judges in real time whether the CNC machine tool A has processing abnormalities , if the processing of CNC machine A is successful, the cloud platform will send the processing task of CNC machine A to CNC machine A, and CNC machine A will process the workpiece according to the assigned task; if the processing of CNC machine A is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com